Kamoa-Kakula to begin copper production within a month

Kamoa-Kakula to begin copper production within a month

Mining crews deliver a record 409,000 tonnes of ore grading 5.71% copper in April, including 121,000 tonnes grading 8.40% copper from the centre of the Kakula Mine

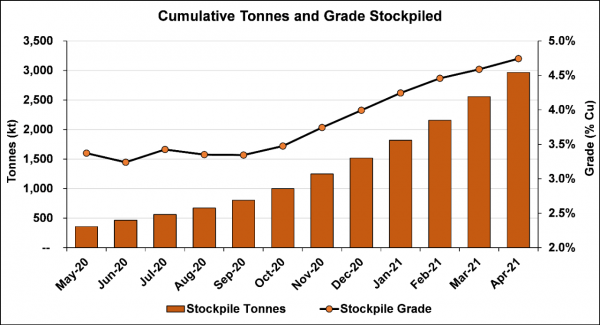

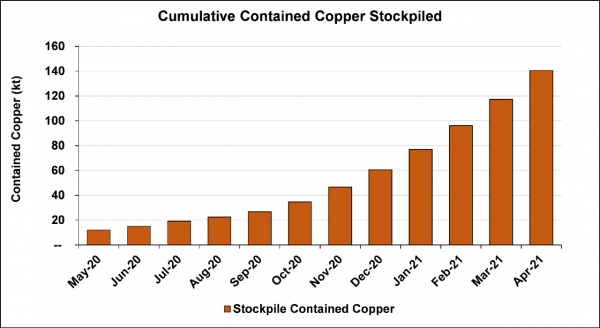

Pre-production ore stockpiles now hold three million tonnes grading 4.74% copper, containing more than 140,000 tonnes of copperKamoa-Kakula’s first phase, 3.8-Mtpa concentrator 98% complete, with advanced-stage commissioning underway

Phase 2 expansion to 7.6 Mtpa progressing well toward a Q3 2022 start-up; study work underway for Phase 3 expansion to 11.4 Mtpa

Agreement signed for an additional 162 MW of hydropower, providing Kamoa-Kakula ample power for future expansions and smelting operations – while supporting the DRC government to bring clean electricity to its people

Executive Co-Chair Robert Friedland to participate in a virtual fireside discussion at the 2021 Goldman Sachs Copper Day on May 5

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce accelerated construction and commissioning progress at the Phase 1 Kamoa-Kakula concentrator plant. The target date for C4 commissioning (milling of ore and first copper concentrate production) has been advanced to the end May or early June –several months ahead of schedule.

Overall construction of the project’s first phase 3.8-Mtpa concentrator plant is essentially complete, with the majority of the C1 (construction complete) certificates signed off. The plant is energized with permanent power and C2 commissioning, which involves electrical, control and instrumentation checks, is well advanced. Water is being circulated in certain areas of the plant, marking the beginning of C3 commissioning. C3 commissioning involves checking for leaks, certain instrument calibration, control loop checks, and is the precursor to C4 commissioning (hot commissioning), which involves processing ore through the plant to produce a copper concentrate.

Overall plant commissioning is running well ahead of schedule, with the first ore expected to be added to the mill by the end of May 2021. Lower-grade ore will be fed into the plant during the C4 commissioning phase, to ensure plant performance and copper recovery are satisfactory before increasing the head grade.

The 409,000 tonnes mined in April comprised 357,000 tonnes grading 5.70% copper from the Kakula Mine, including 121,000 tonnes grading 8.40% copper from the mine’s high-grade centre, and 51,000 tonnes grading 5.85% copper from the Kansoko Mine.

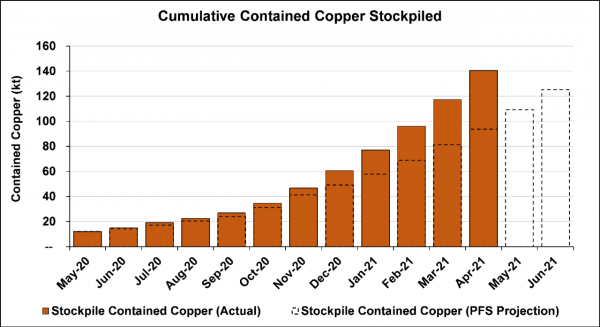

The project’s pre-production surface stockpiles now contain approximately 3.0 million tonnes of high-grade and medium-grade ore at an estimated blended average of 4.74% copper. Kamoa-Kakula now has reached the 3.0-million-tonne target of mined high-grade and medium-grade ore, several months ahead of the timeline estimated in the 2020 pre-feasibility study.

Contained copper in the stockpiles increased by approximately 23,000 tonnes in April – to a cumulative total of more than 140,000 tonnes (the current copper price is approximately US$9,950 a tonne).

Some of the approximately 7,000 employees and contractors who helped to build the Phase 1, 3.8-Mtpa concentrator plant ahead of schedule and within budget.

April’s underground mine development shatters all previous records with advancement of more than 3,625 metres

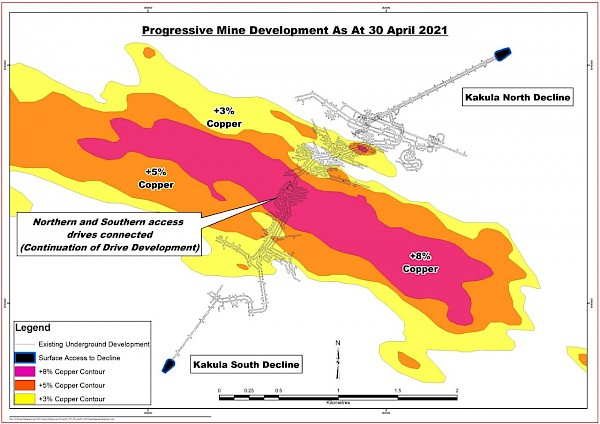

Kamoa-Kakula also set another monthly mine development record in April, with an advancement of more than 3,625 metres, bringing total underground development to approximately 42.2 kilometres – more than 15 kilometres ahead of schedule.

Drift-and-fill stoping operations are progressing well at the Kakula Mine, with the majority of the ore production coming from stoping operations and the remainder coming from mine development activities. Drift-and-fill stoping is a highly-productive mining method of extracting underground ore, where a single tunnel, known as a stope, is extracted leaving an open void that is subsequently backfilled to allow for the extraction of the neighbouring stope in sequence. The backfill plant, which will mix tailings from the processing plant with cement to produce paste backfill, will begin pumping backfill to the underground operations in July.

Mark Farren, Kamoa Copper’s CEO, remarked: “April was another month of great performance by our mining teams, who continue to produce well above plan. We now have reached our 3.0-million-tonne pre-production stockpile target. This stockpile likely is to grow further as our monthly mining rate currently exceeds the Phase 1 milling rate, and only should be drawn down once the Phase 2 concentrator begins operation in mid-2022.

“Even more exciting is the fact that we have been able to significantly bring forward the Phase 1 concentrator commissioning. We now expect to produce our first copper concentrate by the end of May or early June, months ahead of the original schedule.

“We have fantastic people on site, who continue to achieve very tough milestones. We expect to see the same kind of progress during our next challenge of ramping up the plant to nameplate capacity and design recovery. Many of the key contractors have been retained for Phase 2 to ensure continuity and to carry over learnings from Phase 1. Phase 2 construction is moving along nicely and is tracking slightly ahead of plan.”

Mr. Friedland added: “We are proud of the entire Kamoa-Kakula team for their remarkable dedication and accomplishments to deliver our Phase 1 production ahead of schedule and on budget, despite the challenges presented by the COVID-19 pandemic. We would especially like to extend our deepest gratitude to the Kamoa-Kakula leadership team. Their unwavering passion, vision and commitment to excellence is critical to the ongoing transformation and growth of our business.

“The start of production at Kakula marks the beginning of a multi-generational copper mining district, consisting of numerous high-grade mines. We now turn our focus to scaling up this expansive copper region in a manner that is ethically- and socially-responsible, and setting a new global benchmark for the elimination of greenhouse gases in the production of copper that the world urgently needs.”

Robert Friedland to participate in a virtual fireside chat at the 2021 Goldman Sachs Copper Day on May 5 at 11:45 AM ET

Mr. Friedland will discuss Kamoa-Kakula’s expansion plans, the company’s Western Foreland exploration plans, his views on the global copper market and copper’s role in the green energy transition. He also will provide his thoughts on the inevitable differential pricing for all commodities based on their ESG production characteristics as blockchain technology is integrated and smarter markets are established. The Goldman Sachs Copper Day conference is by invitation only for institutional clients.

“Given that Goldman Sachs’ metals strategists recently called copper the “new oil” and predicted copper prices could reach US$15,000 a tonne by 2025, I expect it to be a lively discussion,” said Mr. Friedland.

Members of Ivanhoe’s and Kamoa-Kakula’s multinational senior management teams at Kakula’s Phase 1 concentrator’s pneumatic control valves. L-R: Abraham Li (Director & Deputy General Manager, Kamoa Copper); Steve Amos(Head of Projects, Kamoa Copper); Annebel Oosthuizen (Executive, Finance, Kamoa Copper); Ben Munanga (Chairman, Kamoa Copper); Marna Cloete (President and CFO, Ivanhoe Mines); Mark Farren(CEO, Kamoa Copper); Rochelle de Villiers(Co-CFO, Kamoa Copper);Minty Cai (Co-CFO, Kamoa Copper); and Olivier Binyingo (VP Public Affairs DRC, Ivanhoe Mines).

Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated early average feed grade of more than 6.0% copper, ramping up to 7.6 Mtpa in Q3 2022.

Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, and Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

Given the current copper price environment, Ivanhoe and its partner Zijin are exploring the acceleration of the Kamoa-Kakula Phase 3 concentrator expansion from 7.6 Mtpa to 11.4 Mtpa, which may be fed from expanded mining operations at Kansoko, or new mining areas at Kamoa North (including the Bonanza Zone) and Kakula West.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%).

A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

Kamoa-Kakula is connected to one of the world’s greenest power grids, including power supplied from the newly upgraded Mwadingusha hydropower plant.

Pre-production ore stockpiles total 3.0 million tonnes grading 4.74% copper

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to April 2021.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to April 2021.

Chart 3: Growth in contained copper in surface stockpiles at Kamoa-Kakula to July 2021. Dotted lines denote projections from the 2020 pre-feasibility study.

The ore being mined from the northern portion of the Kakula Mine is transported to surface via the conveyor system and placed on a blended surface stockpile that now contains approximately 1.64 million tonnes grading an estimated 4.93% copper. Additional pre-production ore stockpiles are located at the Kakula southern decline (987,000 tonnes at a blended grade of 4.75% copper) and the Kansoko decline (339,000 tonnes at blended grade of 3.78% copper).

Low-grade ore from surface stockpiles being conveyed to the run-of-mine ore stockpile, to be used in early commissioning of the concentrator plant.

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 1.64 million tonnes grading 4.93% copper. The run-of-mine stockpile in the previous picture is circled in red.

Watch a new Kamoa-Kakula fly-over video showcasing the impressive progress made over the last month: https://vimeo.com/544085443/17f43e0193

Kakula southern decline blended ore stockpiles containing approximately 987,000 tonnes grading 4.75% copper (consisting of 448,000 high-grade tonnes @ 6.55% copper and 538,000 medium grade tonnes @ 3.25% copper).

Kansoko decline blended ore stockpiles containing 339,000 tonnes grading 3.78% copper (consisting of 83,000 high-grade tonnes @ 6.19% copper and 255,000 medium-grade tonnes @ 3.00% copper).

Figure 1: Underground development completed at Kakula Mine to April 30, 2021 (in black).

Construction of the initial 3.8-Mtpa concentrator plant 98% complete; final checks and testing in progress

Overall construction of the project’s first phase, 3.8-Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 98% complete (as of end of April), up from 92% complete at the end of March. The concentrator plant is essentially mechanically complete, with first copper concentrate production scheduled for later this month or early June.

Painting of pipes is underway at Kakula’s Phase 1, 3.8-Mtpa concentrator plant. Foundations for the Phase 2 flotation cells and ball mills are on the right.

Structural steel erection, platework installation and piping and valve installation for the first concentrator plant is effectively complete, as is electrical, controls and instrumentation installation.

The main mine 220-kilovolt (kV) Kamoa Consumer Substation (KCS) has been energized on grid power, as has the 33kV KCS substation. The main plant 33kV substation and all the plant medium-voltage and low-voltage substations also have been energized, and the plant now is electrically live.

Construction complete (C1) sign off is nearing completion with approximately 75% of the certificates signed off and handed over from construction to commissioning. C2 (pre commissioning) commissioning is well underway with some areas (crushing and screening, milling) more than 90% complete. Early C3 activities (checking for leaks, certain instrument calibration, control-loop checks) have started with water being circulated around certain areas in the plant.

Electrical installation at the backfill plant is ongoing and the backfill plant is scheduled to be completed in July, well before paste backfill is required for mining operations.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage. Construction of the tailings storage facility is progressing well and is scheduled to be completed on time to receive tailings from the processing plant.

Phase 1 concentrator plant now energized with permanent hydroelectricity.

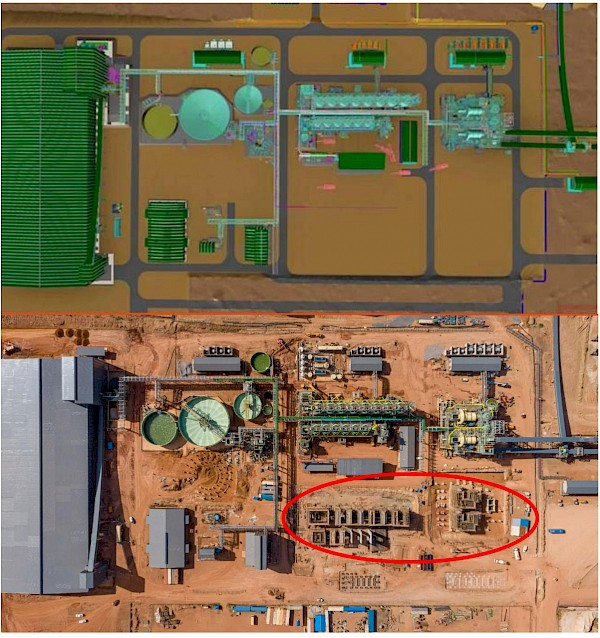

A 3D overhead illustration of the finished Phase 1, 3.8-Mtpa concentrator plant. The picture below shows that construction is essentially complete. Foundations for the Phase 2 concentrator ball mills and flotation cells are circled in red

Kelebogile Choku, Process Engineer with DRA, overseeing the commissioning of the new crushing and screening plant vibrating screen. DRA, a diversified global engineering group headquartered in Perth, Australia, is the Engineering, Procurement and Construction Management (EPCM) contractor for Kamoa-Kakula’s Phase 1 construction.

Kembo Mzemba, Instrument Technician with T3 Projects, wiring a control panel at the high-pressure-grinding-rolls feed bin.

Commissioning of the crushing and screening plant vibrating screen. L-R: Ernest de la Hunt (Mechanical Engineer, DRA); Morne Kruger (Project Manager, DRA); Kelebogile Choku (Process Engineer, DRA); Aldo Groenewald (Commissioning Manager, DRA); and Thys de Beer (Senior Project Manager, DRA).

Newly-trained operators at the Outotec concentrate filtration plant. L-R: Prince Mwenilungena; Teddy Kangwe Kangombe; Sakisa Mazau Papy; Katsmiza Tshisonk; Kazadi Mwyombe Jordan; and Makungu Mushika Idris.

Earthworks and civil works progressing well for the second 3.8-Mtpa concentrator plant, with the first structural steel expected on site in June

Construction of the second 3.8-Mtpa concentrator plant (Phase 2) is progressing well with the current focus on earthworks and civil works. Both earthworks and civil works are tracking slightly ahead of schedule.

Engineering and procurement activities are progressing well. The first two shipments of structural steel and the first three shipments of platework have left the fabricator and are on route to site. The first steel and platework is expected on site in June 2021. The first of the long-lead items of equipment (cone crusher) has arrived on site.

The structural steel, mechanical, piping and plate erection contract has been awarded and the tender document of the electrical, control and instrumentation installation contract will be issued shortly.

Foundations for the Phase 2 flotation cells advancing rapidly.

Watch a short time-lapse video of a day’s construction of the foundations of the Phase 2 concentrator flotation cells: https://vimeo.com/542354139/4847e933e8

Construction of foundations for the Phase 2 ball mills.

Construction of foundations for the Phase 2 high pressure grinding rolls.

Four new large-scale disk filters from FLSmidth, a Danish multinational engineering company, installed in the backfill plant. The filters are used for tailings filtration prior to mixing.

Kamoa-Kakula close to finalizing agreements for the sale of its copper concentrates during Phase 1 operations

Kakula is expected to produce an extremely high-grade, clean copper concentrate (containing over 55% copper) that will be highly coveted by smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Offtake agreements for copper concentrates produced during Phase 1 operations are nearing final, and include arrangements to utilize local smelter capacity to produce blister copper ingots, and also to export concentrates directly.

Upon receipt of final documentation and board approvals from Kamoa-Kakula’s joint-venture partners, as well as from Kamoa Copper SA, Ivanhoe plans to issue a news release providing details of the marketing arrangements.

Contractors constructing a massive parking lot for the transport trucks that will haul Kamoa-Kakula’s copper concentrates to smelters in the DRC and to ports for shipping to international markets.

Kamoa-Kakula’s main 220-kV substation energized with clean, renewable hydropower; upgrading work at the Mwadingusha hydropower plant nearing completion

In December 2020, the 35-kilometre-long double circuit 220-kilovolt (kV) power line to Kamoa-Kakula was connected to the national electrical grid through theNew Western Dispatch substation in Kolwezi. Kamoa-Kakula’s main 220-kV substation was energized with 220-kV power from the national power grid on March 25 and the first of two 33-kV transformers on March 29.

Three of the six new turbines at the Mwadingusha hydropower plant now have been synchronized to the national electrical grid, with each generating unit producing approximately 13 megawatts of power. The completion and commissioning of the hydropower plant’s remaining generating units, in sequence, is in progress.

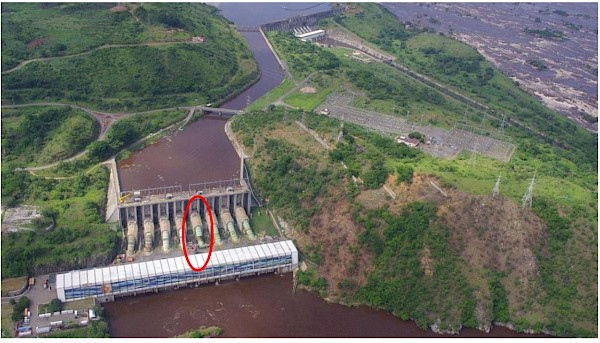

In April, Kamoa-Kakula’s energy company signed an agreement with the DRC’s state-owned power company to upgrade Turbine 5 at the Inga II hydropower complex. Turbine 5 is expected to produce 162 megawatts of renewable hydropower, providing the Kamoa-Kakula Copper Complex and associated smelter with abundant, sustainable electricity for future expansions.

The Mwadingusha hydropower plant soon is expected to deliver 78 megawatts of clean power to the national electrical grid.

Turbine 5 (penstock circled in red) at the Inga II hydropower complex is expected to generate an additional 162 megawatts of clean power after upgrading.

COVID-19 prevention and treatment initiatives successfully maintained, with focus on personnel staying vigilant about COVID safety protocols

Kamoa-Kakula has successfully focused on prevention, preparation and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensured that positive cases were quickly identified, isolated and treated, with cross contamination kept to a minimum. Maintaining this high standard of risk management remains a daily focus, to prevent future cases.

The Kamoa COVID-19 hospital continues to treat patients when required, as construction progresses for the expansion and upgrade of the primary healthcare wing of the hospital. Kamoa-Kakula’s highly experienced doctors and nurses apply the latest medical treatments, supported by a world-leading emergency response and paramedic team.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of the workforce and community members.

Contractor Elie Ngox Tbhisola working on the new primary healthcare wing of the Kamoa hospital.

Overhead view of the Kakula Village workers’ accommodations at dusk.

Kamoa-Kakula constructing an additional 100 fish ponds to expand sustainable aquaculture for increased food security and economic prosperity for local residents

Kamoa-Kakula is constructing another 100 fish ponds in the area surrounding the Kamoa-Kakula Mine, bringing the current number of fish ponds to 137. An additional 25 fish ponds are planned to be constructed, bringing the combined total to 162. The project is anotherKamoa-Kakula Sustainable Livelihoods initiative to further increase food security and economic prosperity in the region.

20 new companies have been created for local ownership of these additional ponds, with each company comprising five residents from local communities.

The Kamoa-Kakula Sustainable Livelihoods Project, established in 2012 by Ivanhoe Mines with the support of U.K.-based Eco-Livelihoods, is significantly contributing to the economic empowerment of residents in 14 communities in the vicinity of Kamoa-Kakula.

Watch a short video of ongoing construction work at the 100 new fish ponds: https://vimeo.com/542348642/9db311dae7

Serge Lumbal, a cook at the Kamoa staff kitchen, with fresh vegetables produced from local community farms – one of Kamoa-Kakula’s local procurement initiatives.

![]()