Kamoa-Kakula Phase 1 concentrator plant produced first copper concentrate on May 25

Kamoa-Kakula Phase 1 concentrator plant produced first copper concentrate on May 25; ramp up toward nameplate capacity of 3.8 million tonnes of ore per year progressing smoothlyFirst copper concentrates shipped to nearby Lualaba Copper SmelterMining crews deliver 406,000 tonnes of ore grading 5.77% copper in May, including 103,000 tonnes grading 8.58% copper from the centre of the Kakula Mine71,000 tonnes of ore grading 4.07% copper delivered directly from Kakula Mine to the concentrator plant to be used during plant ramp upSurface ore stockpiles now hold 3.3 million tonnes grading 4.87% copper, containing more than 160,000 tonnes of copperEngineering and procurement for Phase 2 expansion to 7.6 Mtpa are more than 50% complete; well on track for a Q3 2022 start-upCOVID-19 vaccination program underway for Kamoa Copper’s employees, contractors and local residents

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that commissioning and ramp up of the Kamoa-Kakula Phase 1, 3.8 million-tonne-per-annum (Mtpa) concentrator plant have progressed safely and quickly toward nameplate capacity. Kamoa-Kakula’s initial copper concentrate was produced on May 25th.

First ore was introduced into the concentrator plant on May 20th and the start of copper concentrate production occurred on May 25th, several months ahead of schedule. As of May 27th, 71,000 tonnes of ore grading 4.07% copper had been conveyed directly from Kakula’s underground operations to the concentrator. The team currently is busy with hot commissioning and ramp up of the concentrator.

A total of 406,000 tonnes grading 5.77% copper was mined in May and comprised 365,000 tonnes grading 5.89% copper from the Kakula Mine, including 103,000 tonnes grading 8.58% copper from the mine’s high-grade centre, and 41,000 tonnes grading 4.68% copper from the Kansoko Mine.

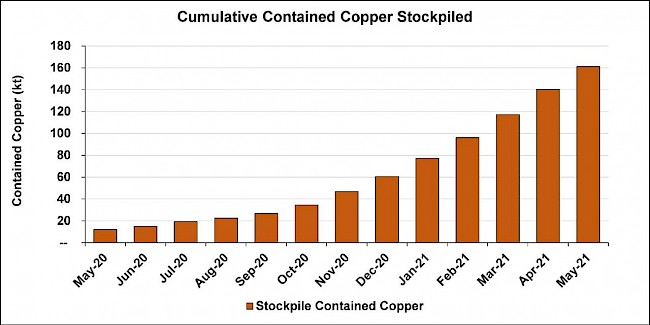

The ore mined in May contained a record 23,400 tonnes of copper. Approximately 20,600 tonnes of contained copper was delivered to the surface stockpiles and the balance was delivered directly to the concentrator plant.

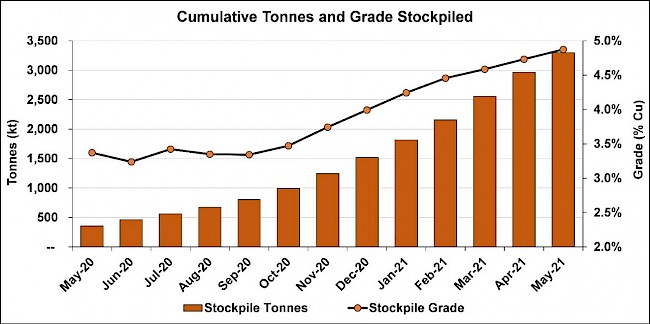

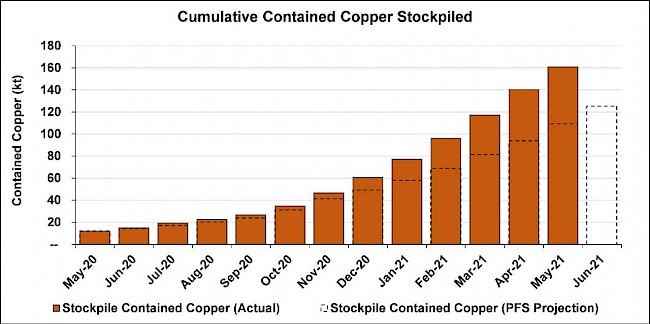

The project’s pre-production surface stockpiles now contain approximately 3.3 million tonnes of high-grade and medium-grade ore at an estimated, blended average of 4.87% copper. Contained copper in the stockpiles at the end of May now totals more than 160,000 tonnes (the current copper price is approximately US$10,200 a tonne).

Watch a new video showcasing the start of production at Kamoa-Kakula: https://vimeo.com/557991671/7e6d5c4ffa

Members of Kamoa Copper’s management team celebrating the first copper concentrate production with members of the DRA team. DRA, a diversified global engineering group headquartered in Perth, Australia, is the Engineering, Procurement and Construction Management (EPCM) contractor for Kamoa-Kakula’s Phase 1 construction.

Moving the copper concentrate for transportation to a local smelter near Kolwezi.

Kamoa-Kakula’s Phase 1 concentrator plant (now in hot commissioning) and the foundations for the Phase 2 plant module are in the red circle. The process water pond and concentrate storage shed are in the foreground.

Mark Farren, Kamoa Copper’s CEO, remarked: “We are delighted with the progress we have made at the Phase 1 concentrator. As promised at the end of April, we have managed to move into full C4 concentrator commissioning ahead of plan, and we now are producing copper concentrate. The next challenge for the processing team is to ramp up the concentrator to nameplate capacity and reach our planned recovery targets.

“The mining team has continued to perform really well, with volumes consistently around the 400,000-tonne-per-month mark. This remains above the steady-state requirements of the Phase 1 concentrator. We will continue to monitor our mining performance against the ramp-up plan of the Phase 2 concentrator to ensure a smooth and efficient ramp up to steady-state production during 2022.”

Steve Amos, Kamoa Copper’s Head of Projects, commented: “We have been very pleased with the smooth start-up and performance of the Phase 1 plant to date. Our in-country construction, commissioning and operations personnel from both the contractor’s and owner’s teams have done a great job of completing construction and cold commissioning of the plant in a timely manner. We now are in the final process of hot commissioning and ramp up.”

Ivanhoe’s guidance for contained copper in concentrate expected to be produced by Kamoa-Kakula for the balance of 2021 is 80,000 to 95,000 tonnes. The figures are on a 100%-project basis and metal reported in concentrate is prior to refining losses or deductions associated with smelter terms.

Kamoa-Kakula’s Phase 1 concentrator plant in operation, with the foundations for the Phase 2 plant on the right.

Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated, early average feed grade of more than 6.0% copper, ramping up to 7.6 Mtpa in Q3 2022.

Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, and phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

Given the current copper price environment, Ivanhoe and its partner Zijin are exploring the acceleration of the Kamoa-Kakula Phase 3 concentrator expansion from 7.6 Mtpa to 11.4 Mtpa, which may be fed from expanded mining operations at Kansoko, or new mining areas at Kamoa North (including the Bonanza Zone) and Kakula West.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%).

A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

In May, members of Kamoa-Kakula’s mine development team witnessed the completion of reaming the Kansoko Mine’s first raise-bored, 5.5-metre-diameter ventilation shaft.

Agreement signed with nearby Lualaba Copper Smelter to produce 99% blister copper in the Democratic Republic of Congo; first delivery of copper concentrates on June 1st

On May 31, 2021, Kamoa Copper signed a 10-year agreement with the Lualaba Copper Smelter (LCS), located outside the town of Kolwezi, for the processing of a portion of Kamoa’s copper concentrate production. Kamoa Copper delivered its first copper concentrates to the Lualaba smelter on June 1st.

LCS is 60%-owned by China Nonferrous Metal Mining Group (CNMC) of Beijing, China. Yunnan Copper of Kunming, China, owns the other 40%.

The agreement follows Ivanhoe Mines and CNMC entering into a strategic partnership with LCS on August 18, 2020, and concludes a negotiation that took place over the last year.

Mark Farren, Kamoa Copper’s CEO (seated right) and Yang Wei, LCS’ CEO (seated left), sign the 10-year agreement to produce 99% blister copper from Kamoa Copper’s concentrate. Joining them at the contract signing are (L-R) Lui Fang, LCS’ Assistant Marketing Manager; Zhang Yu, LCS’ Marketing Contract Controller; Dong Ming, LCS’ Deputy General Manager; Meng Zhiguo, LCS’ Deputy General Manager; Rochelle de Villiers, Kamoa Copper’s CFO; Ben Munanga, Kamoa Copper’s Chairman; Steve Amos, Kamoa Copper’s Head of Projects; and Minty Cai, Kamoa Copper’s CFO.

The smelter, which began operations in early 2020, will treat up to 150,000 wet metric tonnes of copper concentrates from Kamoa-Kakula, in return for a treatment charge and market-based realization fee, and produce blister copper ingots containing approximately 99% copper that will be collected by Kamoa Copper from a storage area at the LCS site.

LCS is the first modern, large, pyro-metallurgical copper smelter built in the Democratic Republic of Congo, and is approximately 40 kilometres from Kamoa-Kakula via the recently-constructed, dedicated by-pass road.

Rochelle de Villiers, Kamoa Copper’s CFO, who is leading the concentrate off-take and marketing negotiations on behalf of the Kamoa Copper joint venture, commented: “Kamoa Copper is pleased to have concluded an agreement with LCS, which will account for just under 40% of the total volumes of concentrates produced by Phase 1, making the most of available in-country smelter capacity. We made our first concentrate deliveries to LCS on June 1st, and we are looking forward to a long-term, mutually beneficial relationship with our new local partner.”

Convoy of trucks departing Kamoa-Kakula on June 1st with the first shipment of copper concentrate, enroute to the Lualaba Copper Smelter approximately 40 kilometres away.

Kakula is expected to produce an extremely high-grade, clean copper concentrate (containing over 55% copper) that will be highly coveted by smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Offtake and export agreements for the balance of the copper concentrates produced during Phase 1 operations are nearing finalization, and include arrangements to export concentrates directly. The company plans to provide an update on Phase 1 copper concentrate off-take arrangements in the near term.

Kamoa Copper also is evaluating the construction of a smelting complex for the production of blister and anode copper. A downstream processing facility has a compelling rationale, significantly reducing the overall volumes of copper concentrate shipped from the mine and the cost of transportation and logistics, export taxes and concentrate treatment charges, as well as producing sulphuric acid as a by-product. There is a strong demand and market for sulphuric acid in the Democratic Republic of Congo to recover oxide copper ores. Copper mines in the Democratic Republic of Congo currently import significant volumes of sulphur and sulphuric acid for the treatment of oxide copper ores.

Blister copper ingots, containing approximately 99% copper, produced at the Lualaba Copper Smelter.

Pre-production ore stockpiles total 3.3 million tonnes grading 4.87% copper

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to May 2021.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to May 2021.

Chart 3: Growth in contained copper in surface stockpiles at Kamoa-Kakula to July 2021. Dotted lines denote projections from the 2020 pre-feasibility study.

Piemme Bukas Amakay, SGS Lab Coordinator, performing chemical analysisin the new on-site assay lab at Kamoa-Kakula.SGS of Geneva, Switzerland is the world’s leading inspection, verification, testing and certification company.

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 1.80 million tonnes grading 5.08% copper.

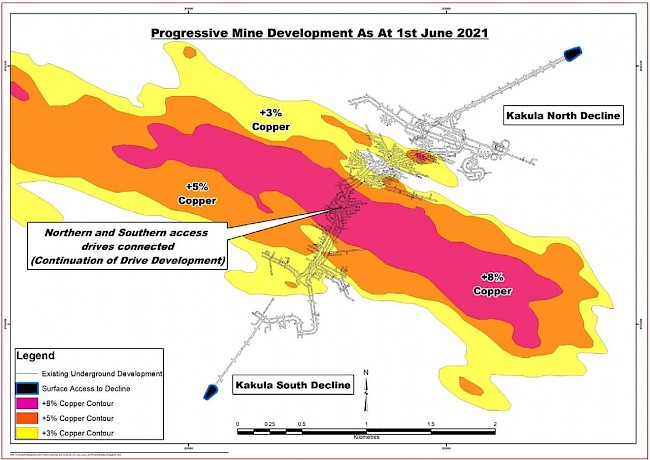

Kamoa-Kakula achieved an advancement of more than 3,525 metres in May, bringing total underground development to approximately 45.7 kilometres – more than 16.5 kilometres ahead of schedule.

Drift-and-fill stoping operations are progressing well at the Kakula Mine, with the majority of the ore production coming from stoping operations and the remainder coming from mine development activities. Drift-and-fill stoping is a highly-productive mining method of extracting underground ore, where a single tunnel, known as a stope, is extracted leaving an open void that is subsequently backfilled to allow for the extraction of the neighbouring stope in sequence. The backfill plant, which will mix tailings from the processing plant with cement to produce paste backfill, will begin pumping backfill to the underground operations in July.

At both the Kakula South and Kansoko declines, high-grade ore of +6% copper is being stored in separate surface stockpiles that will provide the operating team with tremendous flexibility for optimizing the high-grade ore processed in the Phase 1 and Phase 2 concentrator plants.

Kakula southern decline high-grade and medium-grade ore stockpiles containing a combined 1.12 million tonnes grading 4.89% copper (consisting of 516,000 high-grade tonnes @ 6.69% copper and 605,000 medium-grade tonnes @ 3.35% copper), with the Kakula northern decline and the Kamoa-Kakula concentrator plant in the background.

Kansoko decline blended high-grade and medium-grade ore stockpiles containing a combined 380,000 tonnes grading 3.86% copper (consisting of 104,000 high-grade tonnes @ 6.18% copper and 275,000 medium-grade tonnes @ 2.99% copper). Kansoko is located approximately 10 kilometres north of the Kamoa-Kakula concentrator plant.

Figure 1: Underground development completed at Kakula Mine to June1, 2021 (in black).

(L-R) Clive Kabalibali, Surveyor; Pierrot Kasongo, Shift Boss; and Yannick Tshala Ntambwe, Surveyor, in one of the Kakula Mine’s large, high-grade mining drifts.

Leandro Sanga, Underground Supervisor (left), and Mack Mwambu, underground worker, installing drive belts for a water pump at the Kakula Mine.

Construction and pre-commissioning of the project’s first phase, 3.8-Mtpa concentrator plant and associated facilities essentially complete, with C4 (hot commissioning) activities underway

First ore was introduced into the ball mills on May 20th, marking the start of C4 commissioning. This was followed by the tailings dam receiving tailings on May 21st and first concentrate production on May25th. The initial 48-hour run test has been completed, which included ramping up the mill throughput to 90% of nameplate capacity. The next step includes running the plant for 72 hours as part of the final performance run. This will conclude the C4 commissioning activities.

The concentrator plant currently is being operated and maintained by the Kamoa operations and engineering teams with assistance from the project commissioning engineers. The operations team has been on site for the last few months receiving classroom and on-the-job training.

Electrical installation at the backfill plant is ongoing and the backfill plant is scheduled to be completed in July, well before paste backfill is required for mining operations.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage. Construction of the tailings storage facility is progressing well and is scheduled to be completed on time to receive tailings from the processing plant.

Toussaint Tshipamba, IT Technician, installing fiber-optic cables for the concentrator’s plant control room.

Aerial view of the contractors’ accommodations at Kamoa-Kakula.

Earthworks and civil works progressing well for the second 3.8-Mtpa concentrator plant, with the first structural steel expected on site in June

Construction of the second 3.8-Mtpa concentrator plant (Phase 2) is progressing well with the current focus on earthworks and civil works. Structural steel erection is expected to start this month. Both earthworks and civil works are tracking slightly ahead of schedule.

Engineering and procurement activities are progressing well with both more than 50% complete. Fabrication of structural steel and platework is nearing completion with the first structural steel having arrived on site.

Manufacturing of all long-lead items of equipment is well advanced with a number of items complete. Equipment for the Phase 2 plant has started to arrive on site.

The structural steel, mechanical, piping and plate erection contract has been awarded and the contractor has started to mobilize. Tender documents for the electrical, control and instrumentation installation have been issued.

Foundations for the Phase 2 concentrator plant module are advancing quickly.

Foundations for the Phase 2 high-pressure-grinding-rolls (HPGR) stockpile (in red circle) alongside the Phase 1 HPGR stockpile.

Upgrading work at the Mwadingusha hydropower plant nearing completion

Four of the six new turbines at the Mwadingusha hydropower plant now have been synchronized to the national electrical grid, with each generating unit producing approximately 13 megawatts (MW) of power. The completion and commissioning of the hydropower plant’s remaining two generating units, in sequence, is in progress.

In April, Kamoa-Kakula’s energy company signed an agreement with the Democratic Republic of Congo’s state-owned power company to upgrade Turbine 5 at the Inga II hydropower complex. Turbine 5 is expected to produce 162 MW of renewable hydropower, providing the Kamoa-Kakula Copper Complex and associated smelter with abundant, sustainable electricity for future expansions.

Four of six generating units at the Mwadingusha hydropower plant have been upgraded. Each unit is delivering approximately 13 MW of clean power to the national electrical grid.

Kamoa Copper partners with the Democratic Republic of Congo government, UNICEF and other stakeholders to administer COVID-19 vaccinations

Kamoa-Kakula has successfully focused on prevention, preparation and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensured that positive cases were quickly identified, isolated and treated, with cross contamination kept to a minimum. Maintaining this high standard of risk management remains a daily focus, to prevent future cases.

Kamoa Copper has secured an initial supply of 1,000 dosages of the AstraZeneca vaccine for Kamoa employees, contractors and Democratic Republic of Congo residents who live in the mine’s host communities. A second supply of 1,000 dosages is expected in June. The second dose will be administered 8 to 12 weeks after the first and a certificate of vaccination completion will be issued to those who have received two doses.

The Kamoa COVID-19 hospital continues to treat patients when required, as construction progresses for the expansion and upgrade of the primary healthcare wing of the hospital. Kamoa-Kakula’s highly-experienced doctors and nurses apply the latest medical treatments, supported by a world-leading emergency response and paramedic team.

Dr. John Botomwito, Health Manager at Kamoa Copper S.A., commented: “Kamoa is continually working closely with national and provincial stakeholders to improve access to healthcare in the Lualaba Province.”

Kamoa is one of 15 sites in the province where COVID-19 vaccination programs are being rolled-out in an effort to curb the spread of the virus.

As the pandemic evolves, the medical team at the Kamoa hospital continues to review and update risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of employees and community members.

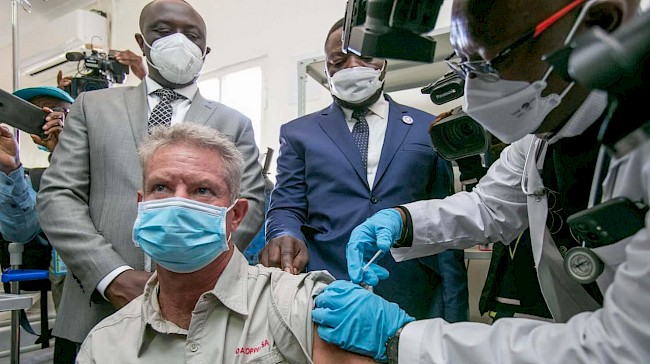

Dr. John Botomwito, Kamoa Copper’s Health Manager (right), administering a COVID-19 vaccination to Mark Farren, Kamoa Copper’s CEO. Looking on are Kabwit Ngoie Jules, Lualaba Provincial Minister of Health and Social Welfare (back, left), andDr. Patrick Tshinawej Mukiny, Lualaba Provincial PEV (vaccination campaign office) Coordinator (back, right).

Excellent progress is being made on the new primary healthcare wing of the Kamoa hospital.

Kamoa-Kakula constructing an additional 100 fish ponds to expand sustainable aquaculture for increased food security and economic prosperity for local residents

Kamoa-Kakula is constructing another 100 fish ponds in the area surrounding the Kamoa-Kakula Mine, bringing the current number of fish ponds to 137. An additional 25 fish ponds are planned to be constructed, bringing the combined total to 162. The project is part of Kamoa-Kakula Sustainable Livelihoods’ initiative to further increase food security and economic prosperity in the region.

20 new companies have been created for local ownership of these additional ponds, with each company comprising five residents from local communities.

Harvesting of Tilapia fish by Kakweji Tshikuta Castain, one of the new fish farmers from Kamisange Community and a beneficiary of the new fish ponds under construction.

Vero Kahilo, Seamstress, sewing personal protective equipment at the Kamoa-Kakula Sustainable Livelihoods sewing project. The project, nicknamed Salamah (‘security and peace’ in Swahili), was initiated by Kamoa-Kakula’s Local Economic Development team in 2013.

![]()