Kakula Copper Mine’s northern and southern access tunnels successfully connected

Kakula’s high-grade core now open for immediate development, where the average grade is projected to exceed 8% copper

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun today announced a major milestone in the development of the tier one Kamoa-Kakula Copper Project in the Democratic Republic of Congo (DRC), with the initial joining of the main northern and southern access tunnels at the Kakula Copper Mine ─ the first of multiple, high grade, underground copper mines to be developed on the project’s 400-square-kilometre mining licence.

The Kakula Mine is being developed on the eastern portion of the Kakula Deposit ─ representing less than half of the overall 13.3-kilometre-long (8.3-miles) deposit. The main access tunnels (drives) between the northern and southern declines at the Kakula Mine were connected (holed) in the high-grade core of the deposit, where the average grade is projected to exceed 8% copper.

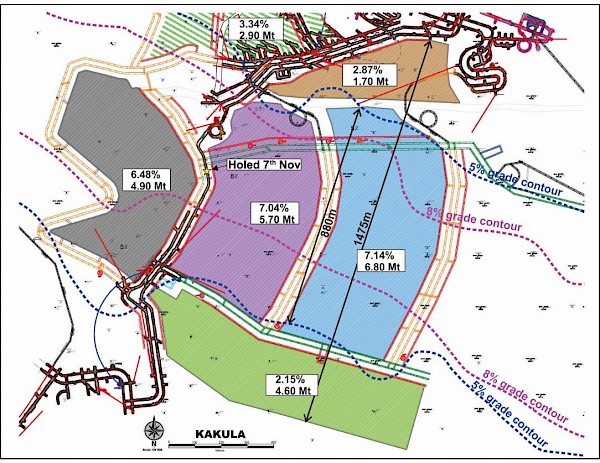

This week’s holing has opened up the first two high grade, drift-and-fill mining blocks totaling 10.6 million tonnes at an average grade of 6.78% copper (5.7 million tonnes @ 7.04% copper and 4.9 million tonnes @ 6.48% copper) near the centre of the deposit (see Figure 1).

“Now that we have initiated the development of Kakula’s first two high-grade ore blocks, it is important to note that these two areas alone contain more than 700,000 tonnes of in-situ copper and approximately 600,000 tonnes of recoverable copper,” said Mr. Friedland. “With copper trading at approximately US$7,000 a tonne, the saleable value of the copper concentrate produced from these initial two blocks exceeds the estimated capital cost to develop both the first and second phases of production at Kamoa-Kakula. This is the true definition of a tier-one mine.”

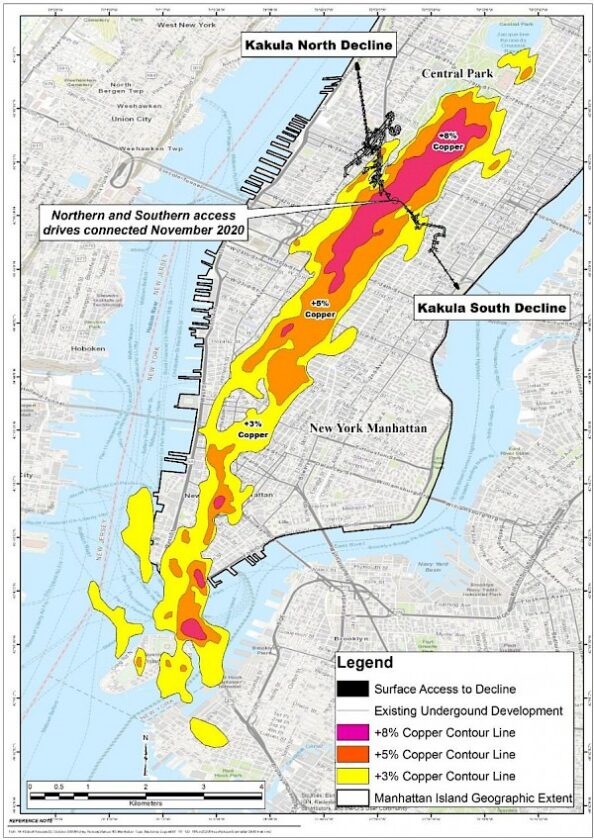

“The tunneling work completed to join Kakula’s northern and southern declines is comparable to driving a major tunnel ─ large enough to drive city buses through ─ from the east side to the west side of the island of Manhattan in New York,” Mr. Friedland added.

The Kakula Mine is expected to have a mine life of approximately 21 years, while the western portion of the Kakula Deposit – Kakula West – is scheduled to be Kamoa-Kakula’s third underground mine to be developed and have a mine life of approximately 16 years.

“The holing is a major achievement and milestone for the project team and our underground mining crews. It opens up the mine’s footprint for ventilation and, more importantly, marks our entry into high-grade ore from both sides of the deposit,” said Mark Farren, Kamoa Copper’s CEO.

“We have moved quickly to open up these high-grade reserves at the core of the Kakula Deposit. We now will complete the ledging work and prepare the drift-and-fill mining areas for production so that we can feed the concentrator plant with high-grade ore directly from underground when the plant starts operations in July 2021.”

“The holing was spot on and we are very pleased with the result. Ventilation has always been a key factor in determining how many underground mining crews can work at the same time. Air now is flowing freely between the northern and southern declines – a distance of more than four kilometres – allowing us to add additional mining crews in the high-grade drift-and-fill blocks as we require them. Each block in the central portions contains up to seven million tonnes of high-grade ore,” Mr. Farren added.

Underground development from the southern decline was performed by mining crews from JMMC, the DRC subsidiary of leading Chinese mining contractor JCHX, while development from the northern decline was performed by Kamoa Copper’s mining crews.

Marna Cloete, Ivanhoe Mines’ President and CFO (right), celebrates Kakula’s first holing with Jan Strydom, Kamoa Copper’s Managerial Leader: Operations (left). Mr. Strydom and his mining crews were instrumental in the successful connection of the main access drives from the northern and southern declines.

Watch a short, time-lapse video of the drilling and blasting process for the holing event: https://vimeo.com/477672587/67ed1b4d74

Members of Kamoa-Kakula’s team of talented Congolese celebrate the holing.

(Left to right) Olivier Binyingo, Ivanhoe Mines’ VP Public Affairs for DRC; Ben Munanga, General Manager, Ivanhoe Mines Energy DRC; Christelle Nday, Admin Office Manager; Lydia Makong, Geologist; Pontien Kalala, Section Manager; Magloire Kashiba, Production Manager; Micheline Kyenge, Geologist; Louis Watum, General Manager Kipushi Project; Didier Masengo, Senior Mine Geologist; Franck Twite, Senior Geology Superintendent; and Numbi Kabale, Ivanhoe Financial Reporting.

Second holing expected by June 2021, opening up 26 million tonnes of ore to feed the initial 3.8-Mtpa concentrator plant

The second set of connection drives is expected to hole by June 2021, opening up an additional high-grade and medium-grade mining block. The width of the initial planned mining blocks of the Kakula orebody measures 1,475 metres, of which 880 metres is in the +5% and +8% copper grade contours (see Figure 1). When the second holing is achieved, ore available for mining will increase to approximately 26 million tonnes.

Phase 1 copper concentrate production from the Kakula Mine is scheduled to begin in July 2021. Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 million tonnes per annum (Mtpa) at an estimated average feed grade of more than 6.0% copper over the first five years of operation.

Phases 1 and 2 combined are forecast to produce up to 427,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

A recent, independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

“After more than 25 years of exploration and development, we are now less than nine months away from unveiling the world’s next truly great copper mine. After hitting one milestone after another, we are now down to the short strokes before we welcome government representatives, institutional investors, and analysts from the world’s leading banks to the mine’s grand opening,” said Mr. Friedland.

Kakula average grade of 6.2% copper over the initial five years of operations; combined Kakula-Kansoko average grade of 4.5% copper over a 37-year mine life

In September 2020, Ivanhoe announced the findings of an independent pre-feasibility study (PFS) for the project’s Phase 2, 7.6-Mtpa operation that evaluates the development of mining activities at both the Kakula Mine, initially at a rate of 3.8 Mtpa and ramping up to 6.0 Mtpa; and the Kansoko Mine, initially at a rate of 1.6 Mtpa to fill the expanded, Phase 2, 7.6-Mtpa concentrator plant at Kakula and ramping up to 6 Mtpa as the reserves at Kakula are depleted.

A few key results for the Kakula-Kansoko 2020 PFS:

- Kakula-Kansoko benefits from an ultra-high feed grade averaging 6.2% copper over the first five years of operations, and 4.5% copper on average over a 37-year mine life.

- An average annual production rate of 331,000 tonnes of copper at a mine-site cash cost of US$0.55 per pound (lb) of copper and total cash cost of US$1.23/lb copper for the first 10 years of operations, and annual copper production of up to 427,000 tonnes by year four. Kakula is expected to produce a very-high-grade copper concentrate of approximately 57% copper, with extremely low arsenic levels.

The mining method for the Kakula Deposit primarily is drift-and-fill using paste backfill; with the exception of a room-and-pillar area close to the northern declines, which will be mined in the early years of production. The paste backfill system will utilize a paste plant located on surface connected to a distribution system that includes a surface pipe network connected to bore holes located at each connection drive on the northern side of the orebody. Approximately 99% of the deposit will be mined using drift-and-fill, which was chosen to maximize the extraction of high-grade Kakula ore.

Figure 1: The successful holing has opened up the first two high grade, drift-and-fill mining blocks shown in purple (5.7 million tonnes @ 7.04% copper) and grey (4.9 million tonnes @ 6.48% copper) shown below.

Note: Tonnes and grades for the central high-grade blocks represent a 7-metre ‘best cut’ horizon within the Mineral Resource model with a basal contact referenced to 1 metre above the bottom contact of the basal siltstone. Tonnes and grade for the medium-grade northern and southern blocks represent a 6-metre ‘best cut’ horizon within the Mineral Resource model with a basal contact referenced to 1 metre above the bottom contact of the basal siltstone. Grade contours are modelled based on the 6-metre-high best cut.

Figure 2: The 13.3-kilometre Kakula Deposit overlain on Manhattan to provide a sense of size of the deposit.

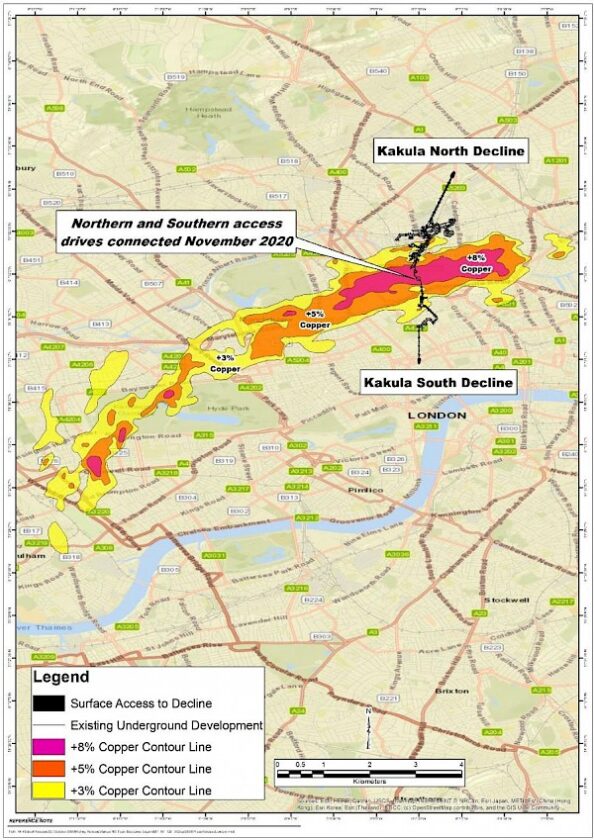

Figure 3: The 13.3-kilometre Kakula Deposit overlain on London.

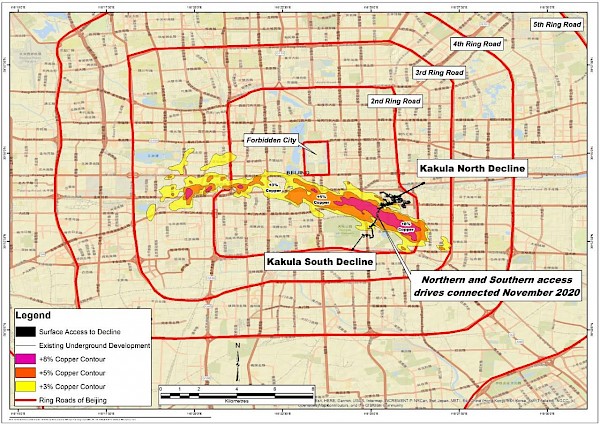

Figure 4: The 13.3-kilometre Kakula Deposit overlain on Beijing.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the DRC government (20%).

Two 220-kilovolt (kV) transformers arriving at the Kakula Mine site earlier this week. Each weighing 85 tonnes, the transformers are the last major pieces of equipment for Phase 1, 3.8-Mtpa operation. They are being installed at the Kakula Mine substation to receive clean, sustainable hydroelectricity from the national grid.

Watch a short, time-lapse video of the arrival and installation of the transformers at the Kakula Mine substation: https://vimeo.com/477680792/5567936d3f

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the DRC and at the Platreef palladium-platinum-nickel-copper-rhodium-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the DRC. Kamoa-Kakula is expected to begin producing copper in July 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi will be powered by clean, renewable hydroelectricity and will be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe also is exploring for new copper discoveries on its wholly-owned Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project.

![]()