Ivanhoe Mines Completes Construction of Kamoa-Kakula’s Phase 3 Concentrator Ahead of Schedule and on Budget

First ore to Phase 3 concentrator achieved on May 26; first Phase 3 concentrate expected in early June

Phase 3 concentrator increases Kamoa-Kakula copper production capacity to more than 600,000 tonnes per annum, making Kamoa-Kakula the fourth-largest copper mining complex globally

Further Kamoa-Kakula growth initiatives in progress, including Project 95, de-bottlenecking of Phase 3 and potential acceleration of Phase 4 expansion

Zero lost-time injuries recorded during the construction of the Phase 3 concentrator

Phase 1 and 2 concentrators produced more than 63,000 tonnes of copper since start of April; a significant improvement resulting from improved power stability

Kamoa-Kakula’s 2024 production guidance maintained at 440,000 to 490,000 tonnes of copper in concentrate

Kolwezi, Democratic Republic of Congo–(Newsfile Corp. – May 28, 2024) – Ivanhoe Mines (TSX: IVN) (OTCQX: IVPAF) Executive Co-Chair Robert Friedland and President Marna Cloete announce today that on May 26, 2024, first ore was fed into the Phase 3 concentrator at the Kamoa-Kakula Copper Complex in the Democratic Republic of the Congo (DRC).

First ore marks the completion of construction of the Phase 3 concentrator, which has been achieved months ahead of schedule and also on budget.

First concentrate is expected in early June, while ramp-up to commercial production is targeted for early in the third quarter.

Ivanhoe Mines’ Founder and Executive Co-Chairman Robert Friedland commented:

“The Kamoa-Kakula operations team continues its industry-leading execution with the early and on-budget delivery of the Phase 3 concentrator and underground mining operations a rare feat in an industry plagued by cost overruns and delays when it comes to complex, world-scale projects.

Meanwhile, we have experienced much-improved power stability over the second quarter following our team’s proactive response to grid instability experienced in the southern DRC grid.

As a result, we’ve seen materially higher head grades and improved production over the past two months. We expect a stronger second quarter from Kamoa-Kakula’s operations, reinforcing our confidence that production will align with annual guidance.

“Given the outperformance of Kamoa-Kakula’s operations to date, including higher than expected throughput and recoveries at the Phase 1 and Phase 2 concentrators, we are now studying options to boost copper production towards our next goal of 800,000 tonnes per annum … a production rate that would propel the Kamoa-Kakula Copper Complex towards being one of the two largest copper producers on our planet.

In addition to the de-bottlenecking of the Phase 3 concentrator and increasing recoveries to 95% via our ‘Project 95’ initiative, we are now also studying options to accelerate the Phase 4 expansion at Kamoa-Kakula to target a throughput rate of at least 20 million tonnes annually.

Given the current copper market, and the expansive copper resources and reserves in proximity of the milling complex, we believe this expanded throughput rate would unlock substantial value for our stakeholders and shareholders in the near and long term.

“It is only early days in terms of the broader copper growth story at Ivanhoe Mines, with our aggressive 70,000-metre drill program at our adjoining, majority-owned Western Foreland licenses … which is now ramping up into the dry season with 10 drill rigs active.

Given that our current Western Foreland resources already total nearly 5 million tonnes contained copper, we also intend to assiduously advance the Makoko, Kiala and Kitoko discoveries towards early production to underpin the further expansion of our copper business.”

Kamoa-Kakula celebrated the first feed of ore into the ball mills of the new Phase 3 concentrator on May 26, 2024.

Kamoa Copper’s projects and operations team standing in front of the new Phase 3 concentrator. The Phase 3 operations team have been trained on Phase 1 and 2 concentrators, which have a similar process design.

The Phase 3 concentrator will process ore from the adjacent Kamoa 1 and 2 underground mines, as well as the connecting Kansoko underground mine.

The design capacity of the Phase 3 concentrator is 30% larger than the original design capacities of the Phase 1 and 2 concentrators, which are located approximately 10 kilometres to the south.

The process design of all three concentrators is comparable, therefore the bulk of the equipment is the same or similar, resulting in a commonality of spare parts, while also leveraging operational and maintenance experience.

The Phase 3 concentrator increases the total design processing capacity of the Kamoa-Kakula Copper Complex to 14.2 million tonnes per annum (Mtpa).

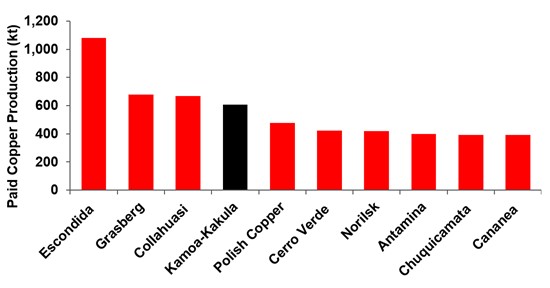

Phase 3 is expected to increase annualized copper production to more than 600,000 tonnes, positioning Kamoa-Kakula as the world’s fourth-largest copper mining complex, and the largest copper mine on the African continent. See Figure 1.

Figure 1. World’s top 10 copper mines estimated for 2025, by paid copper production per annum

Source: Wood Mackenzie, 2023 (based on public disclosure and the Kamoa-Kakula Phase 3 annualized production estimate of approx. 600,000 tonnes copper. (The Kamoa-Kakula data has not been reviewed by Wood Mackenzie).

As of April 30, 2024, a total of 2.25 million tonnes of ore at a grade of 3.1% copper is stored in surface run-of-mine (ROM) stockpiles adjacent to the Phase 3 concentrator.

The stockpiled ore from the Kamoa 1 and Kansoko mines, containing approximately 70,000 tonnes of copper, with the copper price trading at well over $10,000 per tonne, is being used to de-risk the ongoing wet commissioning and ramp-up of the new 5-Mtpa concentrator.

Dry commissioning commenced in early April, with first ore from the ROM stockpiles being fed through the front-end (crushing and screening plant) of the Phase 3 concentrator.

A crushed ore stockpile has been created on the high-pressure grinding rolls (HPGR) feed stockpile area, at the end of the crushing and screening circuit.

Wet commissioning commenced with first feed into the ball mills and the flotation plant on May 26. First concentrate is expected to be produced in early June, with commercial production targeted for early in the third quarter.

Concentrate produced by the Phase 3 concentrator will be partially sold (via toll-smelting at the Lualaba Copper Smelter) to generate cash flow, as well as partially stockpiled in preparation for the commissioning of the on-site, direct-to-blister smelter. Concentrate produced by the Phase 3 concentrator has a higher sulphuric content than the Phase 1 and 2, which requires less external energy input into the smelter during start-up.

Approximately, 70,000 tonnes of Phase 3 concentrate is planned to be stockpiled on-site ahead of the start-up of the smelter.

Kamoa-Kakula’s Phase 3 concentrator expansion was completed months ahead of schedule and will boost production to over 600,000 tonnes of copper per annum once fully ramped up early in Q3 2024.

Kamoa-Kakula’s Phase 3 concentrator has a nameplate throughput of 5 Mtpa. Once ramped-up, study work will commence on de-bottlenecking the milling circuit.

The de-bottlenecking at the Phase 1 and Phase 2 concentrators, completed in February 2023, increased throughput by over 20% above the original design capacity.

Kamoa-Kakula’s Phase 3 ROM stockpile. As of April 30, 2024, Kamoa 1 and Kansoko surface stockpiles adjacent to the Phase 3 concentrator totalled 2.25 million tonnes of ore, at a combined average grade of 3.1% copper.

Significant growth opportunities to further increase copper production with ‘Project 95’, Phase 3 de-bottlenecking program and accelerating Phase 4 expansion

Basic engineering of the previously announced “Project 95” is expected to be completed in the coming weeks. Project 95 is an initiative targeting an increased overall metallurgical copper recovery rate of Kamoa-Kakula’s Phase 1 and 2 concentrators of approximately 95%, up from the current rate of approximately 87%.

Once the Phase 3 concentrator has achieved commercial production, Kamoa-Kakula’s engineering team will gather operating data with the view to initiating a de-bottlenecking program to further increase the Phase 3 concentrator processing capacity above 5 Mtpa.

The Phase 1 and 2 concentrators completed a de-bottlenecking program in February 2023, which increased processing capacity by approximately 20% above the original design throughput.

Following the completion of Phase 3, and given current market conditions, Kamoa-Kakula’s engineering team is investigating the acceleration of the project’s planned Phase 4 expansion.

The Phase 4 concentrator will be positioned adjacent to the Phase 3 concentrator, with a minimum processing capacity of 5 Mtpa, and will share common infrastructure with Phase 3, including the front end (crushing and screening plant), which will reduce capital costs.

An updated life-of-mine integrated development plan for the Kamoa-Kakula Copper Complex, including the Phase 3 expansion, smelter and Project 95, as well as further optimization initiatives and the planned Phase 4 expansion is expected to be completed by the end of 2024.

55 MW of imported power significantly improving production from Phase 1 and 2 concentrators; installation of further on-site backup-power generation capacity well underway

Since mid-March, 15 megawatts (MW) of imported power have been reliably supplied to Kamoa-Kakula from Zambia. In addition, since May 1, 2024, an additional 20 MW of power is being imported from Mozambique via the Zambian interconnector.

The supplemental imported power has had a significant, positive effect on the stability of Kamoa-Kakula’s operations. Total production from April 1, 2024 to date, totals more than 63,000 tonnes of copper in concentrate.

This is a notable improvement from the first quarter, which was impacted by power instability. In addition, head grades have improved in the second quarter in part due to increased underground pumping capacity. Imported power from Mozambique is expected to increase by a further 20 MW imminently.

Kamoa Copper’s engineering team continues to expand its on-site, backup generation capacity to ensure there is on-site redundancy for the current Phase 1 and 2 operations, as well as mining and concentrator operations for Phase 3.

On-site backup-power generator capacity is scheduled to increase, via a phased roll-out, to more than 200 MW by the end of 2024. The generator farm sites are being built adjacent to the Phase 1 and 2 concentrators, and smelter at Kakula, as well as adjacent to the Phase 3 concentrator at Kamoa.

As of May 27, 2024, 63 MW of on-site backup generation capacity is installed at Kamoa-Kakula and that is expected to increase to a total of 123 MW by July. Peak on-site power demand from Phase 1 and 2 operations is approximately 105 MW.

The Phase 3 concentrator will add an additional requirement of approximately 45 MW once fully ramped. In addition, the smelter will require a further 75 MW of power once fully ramped up throughout 2025.

Industry-leading health and safety performance achieved during the construction of the Phase 3 concentrator, with zero lost time injuries

During the 10 million man-hours worked on the construction of the Phase 3 concentrator, not a single lost time injury (LTI) was recorded; a rare industry accomplishment.

Therefore, the lost time injury frequency rate (LTIFR) and total recordable injury frequency rate (TRIFR) for the project were both zero.

Including the smelter and other associated infrastructure projects included in the Phase 3 expansion, over the total 40-million-man hours worked to date, only four LTIs have been recorded and nine recordable injuries.

The health and safety performance set by the engineering and contractor teams is industry-leading with a LTIFR and TRIFR of 0.10 and 0.22 per 1,000,000-man hours worked, respectively.

For comparison, the 2022 International Council on Mining and Metals (ICMM) mining industry average was 2.66 per 1,000,000 man-hours worked.

Graddi Kabeya, Instrumentation Technician with contractor T3 Projects, working on the commissioning of Kamoa-Kakula’s Phase 3 concentrator.

Construction site of the direct-to-blister copper smelter in the foreground, with the Phase 1 and 2 concentrators in the background. The smelter is located approximately 10 km to the south of the new Phase 3 concentrator.

Disclosure of technical information

Disclosures of a scientific or technical nature at the Kamoa-Kakula Copper Complex in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101.

Mr. Amos is not considered independent under NI 43-101 as he is Ivanhoe Mines’ Executive Vice President, Projects. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by Joshua Chitambala, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101.

Mr. Chitambala is not considered independent under NI 43-101 as he is the Resource Manager for Ivanhoe Mines. Mr. Chitambala has verified the other technical data regarding the surface stockpiles disclosed in this news release.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Copper Complex, which is available on the company’s website and under the company’s SEDAR+ profile at www.sedarplus.ca:

.Kamoa-Kakula Integrated Development Plan 2023 Technical Report dated March 6, 2023, prepared by OreWin Pty Ltd.; China Nerin Engineering Co. Ltd.; DRA Global; Epoch Resources; Golder Associates Africa; Metso Outotec Oyj; Paterson and Cooke; SRK Consulting Ltd.; and The MSA Group.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Copper Complex cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

![]()