Ivanhoe Mines announces quarterly profit of $67 million

Ivanhoe Mines announces quarterly profit of $67 million and record quarterly normalized profit of $115 million, driven by income from the Kamoa-Kakula joint venture of $90 million

Ivanhoe Mines reports record Adjusted EBITDA of $203 million for Q2 2024, compared with $126 million for Q1 2024

Kamoa-Kakula Copper Complex sold 95,900 tonnes of payable copper in Q2 2024 and recognized record quarterly revenue of $817 million and record EBITDA of $547 million

Kamoa-Kakula’s quarterly cost of sales total $1.53 per lb. of payable copper; C1 cash costs of $1.52 per lb. at the lower end of guidance

Kamoa-Kakula’s Phase 3 concentrator expansion completed ahead of schedule, boosting annualized production to approx. 600,000 tonnes copper

Smelter project over 85% advanced and on schedule for construction completion by the end of 2024

On July 28, Kamoa-Kakula produced a daily record of 1,614 tonnes of copper, following 16,703 tonnes of ore milled at the Phase 3 concentrator, exceeding nameplate by 19%

Kipushi concentrator completed ahead of schedule, with ramp-up to steady-state operations underway during Q3

Ivanhoe Mines’ (TSX: IVN) (OTCQX: IVPAF) President Marna Cloete and Chief Financial Officer David van Heerden have presented the company’s financial results for the three and six months ended June 30, 2024.

Ivanhoe Mines is a leading Canadian mining company developing and operating its four principal mining and exploration projects in Southern Africa: expanding production at the world-class Kamoa-Kakula Copper Complex in the Democratic Republic of Congo (DRC); ramping-up the ultra-high-grade Kipushi zinc-copper-lead-germanium mine in the DRC; building the tier-one Platreef palladium, rhodium, nickel, platinum, copper and gold development in South Africa; as well as exploring and advancing the expansive exploration licenses of Ivanhoe’s Western Forelands project, which currently hosts the Makoko, Kitoko, and Kiala copper discoveries near Kamoa-Kakula. All figures are in U.S. dollars unless otherwise stated.

FINANCIAL HIGHLIGHTS

-Ivanhoe Mines recorded a profit of $67 million for Q2 2024 compared with a profit of $87 million for Q2 2023. Ivanhoe Mines’ normalized profit for Q2 2024 was $115 million, compared with a normalized profit of $114 million for Q2 2023.

Normalized profit for the quarter excludes the non-cash loss on the fair valuation of the embedded derivative component of the $575 million convertible bond and the non-cash finance costs due to the early redemption of the convertible notes. All convertible notes still outstanding at end of June were redeemed after quarter end.

-Kamoa-Kakula sold 95,900 tonnes of payable copper during Q2 2024, recognizing record revenue of $817 million, record operating profit of $463 million, and record quarterly EBITDA of $547 million.

-Kamoa-Kakula’s cost of sales per pound (lb.) of payable copper sold was $1.53/lb. for Q2 2024 compared with $1.50/lb. and $1.24/lb. in Q1 2024 and Q2 2023, respectively.

Cash cost (C1) per pound of payable copper produced in Q2 2024 totaled $1.52/lb., which is at the lower end of the guidance range of $1.50 to $1.70/lb., compared with $1.57/lb. and $1.41/lb. achieved in Q1 2024 and Q2 2023, respectively.

-Ivanhoe Mines’ Adjusted EBITDA was $203 million for Q2 2024, compared with $172 million for the same period in 2023, including an attributable EBITDA share from Kamoa-Kakula.

-Ivanhoe Mines has a strong balance sheet with cash and cash equivalents of $246 million on hand as at June 30, 2024, with little debt at the corporate level following the redemption of the convertible notes.

Ivanhoe expects cash flow from Kamoa-Kakula’s Phase 1, 2, and 3 operations, as well as project level financing facilities to be sufficient to fund outstanding capital cost requirements at current copper prices, which are largely related to the completion of the smelter complex and associated ramp-up activities.

-At Kamoa-Kakula, joint venture company Kamoa Copper drew a further $200 million during the quarter under a term finance facility with ABSA of Johannesburg, South Africa, Africa Finance Corporation (AFC) of Lagos, Nigeria, Rawbank of Kinshasa, DRC, and FirstBank of Lagos, Nigeria.

The new funding facilities will be used to fund both the Phase 3 expansion of Kamoa-Kakula and expanded working capital, as well as future growth, such as Project 95. This brings total Kamoa-Kakula joint-venture in-country term loans and working capital facilities to $800 million, at attractive interest rates of less than 9%.

-At Kipushi, Trafigura and CITIC Metal, off-takers for approximately two thirds of the zinc concentrate production, have each provided a loan facility to Kipushi Corporation (KICO) for $60 million over the five-year term of the off-take contract, at a rate of interest SOFR, plus 6%. Both these loan facilities were drawn in July 2024. A bank facility has also been signed and drawn with domestic lender FirstBank DRC for $50 million at SOFR plus 4.5%.

OPERATIONAL HIGHLIGHTS

-Quarterly production of 100,812 tonnes of copper in concentrate was achieved at Kamoa-Kakula for Q2 2024, compared with 86,203 tonnes in Q1 2024 and 103,786 tonnes in Q2 2023.

-Over the first six months of 2024, Kamoa-Kakula produced a total of 187,015 tonnes of copper in concentrate. With the ramp-up to steady state of the Phase 3 concentrator expected to be complete in August 2024, boosting annual copper production capacity to over 600,000 tonnes, Kamoa-Kakula’s 2024 production guidance is maintained at between 440,000 – 490,000 tonnes of copper.

-Kamoa-Kakula’s Phase 1 and 2 concentrators milled 2.29 million tonnes of ore during the second quarter at an average feed grade of 5.04% copper, benefitting from improved power availability including imported power via the Zambian interconnector, which is now up to 65 megawatts (MW). On-site back-up power generation capacity has been increased to 135 MW with commissioning nearing completion.

-First ore into Kamoa-Kakula’s Phase 3 concentrator was achieved on May 26, 2024, up to two quarters ahead of the originally announced schedule, with first concentrate reported on June 10, 2024. The Phase 3 concentrator produced 1,100 tonnes of copper in concentrate for the remainder of June.

-After quarter end, Kamoa-Kakula’s Phase 1, 2 and 3 concentrators achieved a daily production record of 1,614 tonnes of copper. The record consisted of 306 tonnes of copper from the Phase 3 concentrator, in addition to 1,308 tonnes from Phase 1 and 2. Phase 3 also achieved a daily milling record 16,703 tonnes of ore, exceeding nameplate capacity of 5 million tonnes per annum (Mtpa) by 19%.

-Kamoa-Kakula’s 500,000-tonne-per-annum on-site, direct-to-blister copper smelter and the refurbishment of Turbine #5 at the Inga II hydroelectric facility are advancing on schedule. Construction completion of the smelter is expected by the end of 2024, and Turbine #5 by Q1 2025.

-Basic engineering of “Project 95” at Kamoa-Kakula is now complete, with engineering contractor tendering and early procurement activities now underway. A capital cost of $198 million is estimated for concentrator modifications, plus $102 million in capital costs brought forward for a new tailings storage cell.

Increased recovery to 95% is expected to boost average annualized copper production by up to 30,000 tonnes from the Phase 1 and 2 concentrators. Project execution is expected to take 18 months.

-First feed of ore into the Kipushi concentrator from the surface run-of-mine (ROM) stockpiles was achieved on May 31, 2024, marking the completion of construction ahead of schedule.

The first batch of zinc concentrate production was achieved two weeks later, on June 14, 2024. Ramp-up of the Kipushi concentrator to steady-state production is expected in September.

-Kipushi’s 2024 production guidance is between 100,000 – 140,000 tonnes of zinc in concentrate.

-Basic engineering has already commenced on de-bottlenecking initiatives of the Kipushi concentrator, to target a 20% increase in processing capacity to 960,000 tonnes of ore per annum.

The de-bottlenecking program is expected to take approximately nine months, based on the availability of long-lead order equipment.

-Kipushi will be the lowest greenhouse gas emitter per tonne of zinc produced. On a Scope 1 and 2 basis (reported from ore to mine gate), Kipushi’s greenhouse gas (GHG) emissions intensity for 2025 is expected to be 0.019 equivalent tonnes of carbon dioxide per tonne of contained zinc produced (t CO2-e / t Zn).

This comfortably ranks Kipushi at the bottom of the Scope 1 and 2 GHG emissions curve, according to independent industry experts Skarn Associates.

-Ivanhoe continues its expansive copper exploration program on its Western Foreland licenses adjacent to Kamoa-Kakula. The company’s 2024 exploration program consists of 70,000 metres of diamond-core drilling, with 39,000 metres completed during H1 2024. Drilling during Q2 2024 was mostly focused on Kitoko and Makoko West. Nine drill rigs were in operation at quarter end.

-Construction of Platreef’s Phase 1 concentrator was completed on schedule after the quarter’s end. Cold commissioning has started, with water being fed through the concentrator.

The concentrator will be placed on care and maintenance until H2 2025, as Shaft 1 prioritizes the hoisting of waste from the development required to bring forward the start of Phase 2.

-Work continues on the updated feasibility study to accelerate Platreef’s Phase 2, as well as the preliminary economic assessment of the new Phase 3 expansion. Both studies are expected to be completed in the fourth quarter.

-Construction of Platreef’s Shaft 2 headgear now is approximately 60% complete. Construction activities are advancing well on the installation of 1,124 tonnes of internal structural steel inside Shaft 2’s headgear.

For the second quarter, the group achieved an industry-leading combined Lost Time Injury Frequency Rate (LTIFR) of 0.22 per 1,000,000 hours worked and a Total Recordable Injury Frequency Rate (TRIFR) of 0.82 per 1,000,000 hours worked. Regrettably, there was one fatality in the group during the quarter, which occurred at Kamoa-Kakula.

Principal projects and review of activities

1. Kamoa-Kakula Copper Complex

39.6%-owned by Ivanhoe Mines

Democratic Republic of Congo

The Kamoa-Kakula Copper Complex is operated as the Kamoa Holding joint venture between Ivanhoe Mines and Zijin Mining. The project is approximately 25 kilometres southwest of the town of Kolwezi and about 270 kilometres west of Lubumbashi. Kamoa-Kakula’s Phase 1 concentrator began producing copper in May 2021.

The Phase 2 concentrator, completed in April 2022, doubled nameplate production capacity to 400,000 tonnes of copper per annum.

A debottlenecking program, completed 10 months later in February 2023, further increased copper production capacity to 450,000 tonnes per annum.

The Phase 3 concentrator, completed in June 2024, increased copper production capacity to over 600,000 tonnes per annum, ranking the Kamoa-Kakula Copper Complex as the world’s third-largest copper mining operation by international mining consultant Wood Mackenzie.

Ivanhoe sold a 49.5% share interest in Kamoa Holding Limited (Kamoa Holding) to Zijin Mining and a 1% share interest in Kamoa Holding to privately owned Crystal River in December 2015.

Kamoa Holding holds an 80% interest in the project. Ivanhoe and Zijin Mining each hold an indirect 39.6% interest in Kamoa-Kakula, Crystal River holds an indirect 0.8% interest, and the DRC government holds a direct 20% interest. Kamoa-Kakula’s full-time employee workforce is approximately 5,500 and is over 90% Congolese.

Kamoa-Kakula summary of operating and financial data

| Q2 2024 | Q1 2024 | Q4 2023 | Q3 2023 | Q2 2023 | |||||||||||

| Ore tonnes milled (000’s tonnes) | 2,381(1 | ) | 2,061 | 2,133 | 2,236 | 2,244 | |||||||||

| Copper ore grade processed (%) | 4.91%(1 | ) | 4.80% | 4.95% | 5.37% | 5.21% | |||||||||

| Copper recovery (%) | 86.7%(1 | ) | 87.4% | 87.9% | 87.2% | 87.2% | |||||||||

| Copper in concentrate produced (tonnes) | 100,812 | 86,203 | 92,215 | 103,947 | 103,786 | ||||||||||

| Payable copper sold (tonnes) | 95,900 | 85,155 | 90,967 | 96,509 | 101,526 | ||||||||||

| Cost of sales per pound ($ per lb.) | 1.53 | 1.50 | 1.50 | 1.34 | 1.24 | ||||||||||

| Cash cost (C1) ($ per lb.) | 1.52 | 1.57 | 1.53 | 1.46 | 1.41 | ||||||||||

| Realized copper price ($ per lb.) | 4.34 | 3.82 | 3.71 | 3.84 | 3.79 | ||||||||||

| Sales revenue before remeasurement ($’000) | 813,817 | 612,496 | 625,983 | 681,821 | 729,924 | ||||||||||

| Remeasurement of contract receivables ($’000) | 3,256 | 5,824 | (8,365 | ) | 13,014 | (27,542 | ) | ||||||||

| Sales revenue after remeasurement ($’000) | 817,073 | 618,320 | 617,618 | 694,835 | 702,382 | ||||||||||

| EBITDA ($’000) | 547,257 | 364,893 | 343,899 | 423,211 | 456,628 | ||||||||||

| EBITDA margin (% of sales revenue) | 67% | 59% | 56% | 61% | 65% |

All figures in the above tables are on a 100%-project basis. Metal reported in concentrate is before refining losses or deductions associated with smelter terms.

This release includes “EBITDA”, “Adjusted EBITDA”, “EBITDA margin”, and “cash cost (C1)” which are non-GAAP financial performance measures.

For a detailed description of each of the non-GAAP financial performance measures used herein and a detailed reconciliation to the most directly comparable measure under IFRS, please refer to the non-GAAP Financial Performance Measures section of this release.

(1) Blended figures across the Phase 1, 2, and 3 concentrators, following the commencement of Phase 3 concentrator in June 2024.

Excluding Phase 3, the Phase 1 and 2 concentrators milled 2,288,000 tonnes of ore at an average feed grade of 5.04% with an average recovery of 86.9%. No concentrate produced by the Phase 3 concentrator was sold during the quarter.

C1 cash cost per pound of payable copper produced can be further broken down as follows:

| Q2 2024 | Q1 2024 | Q4 2023 | Q3 2023 | Q2 2023 | ||||||||||||||

| Mining | ($ per lb.) | 0.45 | 0.44 | 0.38 | 0.41 | 0.39 | ||||||||||||

| Processing | ($ per lb.) | 0.21 | 0.23 | 0.24 | 0.20 | 0.19 | ||||||||||||

| Logistics charges (delivered to China) | ($ per lb.) | 0.48 | 0.50 | 0.50 | 0.46 | 0.45 | ||||||||||||

| TC, RC, smelter charges | ($ per lb.) | 0.25 | 0.25 | 0.26 | 0.25 | 0.25 | ||||||||||||

| General & Administrative | ($ per lb.) | 0.13 | 0.15 | 0.15 | 0.14 | 0.13 | ||||||||||||

| Cash cost (C1) per pound of payable copper produced | ($ per lb.) | 1.52 | 1.57 | 1.53 | 1.46 | 1.41 |

Cash cost (C1) is prepared on a basis consistent with the industry standard definitions by Wood Mackenzie cost guidelines but are not measures recognized under IFRS.

In calculating the C1 cash cost, the costs are measured on the same basis as the Company’s share of profit from the Kamoa Holding joint venture that is contained in the financial statements.

C1 cash cost is used by management to evaluate operating performance and include all direct mining, processing, and general and administrative costs.

Smelter charges and freight deductions on sales to the final port of destination, which are recognized as a component of sales revenues, are added to C1 cash cost to arrive at an approximate cost of delivered, finished metal. C1 cash cost excludes royalties, production taxes, and non-routine charges as they are not direct production costs.

All figures are on a 100% project basis and metal reported in concentrate is before refining losses or deductions associated with smelter terms.

Kamoa-Kakula Phase 1, 2, and 3 operations produced 100,812 tonnes of copper in concentrate in Q2 2024

Kamoa-Kakula produced 100,812 tonnes of copper in concentrate in the second quarter of 2024. This includes 99,712 tonnes from the Phase 1 and 2 concentrators and 1,100 tonnes of copper from the Phase 3 concentrator.

Kamoa-Kakula’s Phase 1 and 2 concentrators milled approximately 2.29 million tonnes of ore during the second quarter at an average feed grade of 5.04% copper. Copper flotation recoveries for the quarter averaged 87%.

Kamoa-Kakula’s Phase 3 concentrator was completed up to two quarters ahead of the originally announced schedule and produced its first batch of concentrate on June 10, 2024.

The Phase 3 concentrator is undergoing ramp-up to steady-state production, which is expected in August, taking the production capacity of the Kamoa-Kakula Copper Complex to over 600,000 tonnes per annum.

Ramp-up activities are progressing as planned and therefore, annual production guidance for Kamoa-Kakula is maintained at between 440,000 and 490,000 tonnes of copper in concentrate for 2024.

As of June 30, 2024, a total of 4.82 million tonnes of ore at an average grade of 3.26% copper is stored in multiple surface ROM stockpiles across the Kamoa-Kakula Copper Complex.

This includes 2.31 million tonnes of ore at an average feed grade of 3.72% at Kakula and 2.51 million tonnes of ore at an average grade of 2.85% at Kamoa and Kansoko.

The stockpiled ore, from the Kamoa and Kansoko mines, contains over 70,000 tonnes of copper and is being used for the ramp-up of the new Phase 3 concentrator.

After the quarter ended on July 28, the combined Phase 1, 2, and 3 operations achieved a daily production record of 1,614 tonnes of copper in concentrate.

The record included 306 tonnes of copper from the Phase 3 concentrator, which milled a record 16,703 tonnes of ore over the 24 hours. The Phase 3 milling record was approximately 19% above the nameplate processing capacity of 5 million tonnes per annum.

Kamoa Copper continues to work closely with the DRC’s state-owned power company, La Société Nationale d’Electricité (SNEL), to deliver solutions for the identified causes of instability experienced across the southern DRC’s grid infrastructure since late 2022.

The project work, which is budgeted at up to $200 million and funded by Kamoa Holding, commenced in March 2024 and is expected to be completed in H2 2025. The funding is assigned to increasing transmission capacity and improving the reliability of the grid.

The project work consists of grid infrastructure upgrades, such as an increase in grid capacity between the Inga II dam and Kolwezi, a new harmonic filter at the Inga Converter Station, as well as a new static compensator at the Kolwezi Converter Station. In addition, various smaller initiatives have been identified to strengthen the transmission capability and improve the long-term stability of the southern grid.

This includes the restringing of powerlines in the southern grid and repairs to the direct current (DC) infrastructure. In addition to this, Ivanhoe Mines Energy is working with SNEL to put in place maintenance contracts to maintain key generation capacity and transmission infrastructure.

Imported power via Zambia Interconnector increased to 65 MW, significantly improving grid stability and Kamoa-Kakula’s copper production

During the second quarter, grid-supplied power to Kamoa-Kakula was supplemented by 55 MW of imported power from Zambia and Mozambique, via the Zambian interconnector.

Kamoa-Kakula’s executive team is targeting that imported power will increase by up to a further 20 MW by the end of the third quarter.

Imported power as at July 30 has increased to 65 MW. Subject to capacity availability in the first half of 2025, imported power is then expected to increase to 100 MW.

Other power-generating projects have been initiated to de-risk the current and future operations over the short to medium term, while the grid infrastructure upgrades are completed.

Kamoa Copper’s engineering team is currently expanding its on-site backup generation capacity to ensure there is on-site redundancy for the current Phase 1, 2, and 3 operations.

On-site backup-power generator capacity is scheduled to increase, via a phased roll-out, to a total of over 200 MW in time for the completion of the direct-to-blister copper smelter in early 2025, as shown in Figure 1. The generator farm sites are being built adjacent to the Phase 1 and 2 concentrators, and smelter at Kakula, as well as adjacent to the Phase 3 concentrator at Kamoa.

An additional 72 MW of new generators were delivered to site in July, increasing the on-site generation capacity to 135 MW. Installation of the new generators is complete, with commissioning expected to be completed in early August.

As shown in Figure 1, the power requirement for Phase 3 will be 45 MW once fully ramped up to steady state from August 2024. In addition, the smelter will require a further 75 MW of power once fully ramped up to steady state.

Figure 1. Kamoa-Kakula’s power demand profile versus the projected phased rollout of on-site, back-up generation capacity and imported grid power, supplementing existing domestically-supplied power by SNEL (MW).

Construction of the Phase 3 concentrator plant and associated infrastructure complete, with production ramp-up underway

First ore to Kamoa-Kakula’s Phase 3 concentrator was achieved on May 26, 2024, up to two quarters ahead of the originally announced schedule, with first concentrate reported on June 10, 2024.

The new 5-Mtpa Phase 3 concentrator is located adjacent to the Kamoa underground mines, approximately 10 kilometres north of the Phase 1 and 2 concentrators located above the Kakula underground mine. Since June 10, 2024, the Phase 3 concentrator has produced 1,100 tonnes of copper in concentrate.

The Phase 3 concentrator is 30% larger in capacity, compared with the Phase 1 and 2 concentrators. The process design is very similar, therefore the bulk of the equipment is the same or similar to that installed in the Phase 1 and 2 concentrators, resulting in a commonality of spare parts, while also leveraging prior operational and maintenance experience.

Ramp-up to steady state production of the Phase 3 concentrator is expected in August, following the commissioning of the fine-grinding equipment.

Once complete, Kamoa-Kakula will have a total processing capacity of 14.2 Mtpa, producing over 600,000 tonnes of copper per annum. This positions Kamoa-Kakula as the world’s third-largest copper mining complex, and the largest copper mine on the African continent as shown in Figure 2.

Figure 2. World’s top 10 copper mining operations estimated for 2025, by paid copper production per annum (kt)

Source: Wood Mackenzie, 2024 (based on public disclosure and the Kamoa-Kakula Phase 3 annualized production estimate of approx. 600,000 tonnes of copper). (The Kamoa-Kakula data has not been reviewed by Wood Mackenzie).

Kamoa-Kakula’s Phase 3 expansion, consists of two new underground mines called Kamoa 1 and Kamoa 2, as well as the existing Kansoko Mine. The Kamoa 1 and Kamoa 2 mines share a single box cut with a twin service-and-conveyor decline.

The direct-to-blister copper smelter project is over 85% complete and on schedule for construction completion by the end of 2024

The Phase 3 expansion also includes the construction of Africa’s largest smelter, which will have a capacity of 500,000 tonnes of >99%-pure blister-anode copper per annum.

The direct-to-blister flash smelter is being built adjacent to the existing Phase 1 and Phase 2 concentrator plants. The smelter will incorporate leading-edge technology supplied by Metso Finland and will comply with the world-leading International Finance Corporation’s (IFC) emissions standards.

The smelter project is over 85% complete and is on schedule for construction completion by the end of 2024, furnace heat-up is expected to start in Q1 2025.

Of a total of approximately 73,000 tonnes of equipment and materials, 60,000 tonnes have been delivered to site with an additional 13,000 tonnes en route. The remaining equipment will be delivered in the next two months.

Civil construction and structural erection are nearing completion with installation of mechanical equipment and piping well advanced. Over 100 km of cooling water piping has already been installed around the direct to blister furnace.

In June, a milestone was achieved with the start of refractory installation for the electric slag-cleaning furnace. Electrical installation has commenced in all areas. Some early commissioning activities are due to start in August.

Recruitment and training of the 950-strong operational team is well advanced with all management and technical personnel on-boarded. Procurement of maintenance spares and start-up consumables is also well-advanced.

The smelter will have a processing capacity of approximately 1.2 Mtpa of dry concentrate feed and is designed to run on a blend of concentrate produced from the Kakula (Phase 1 and 2) and Kamoa (Phase 3 and future Phase 4) concentrators.

As per the Kamoa-Kakula 2023 Integrated Development Plan, the smelter is projected to process approximately 80% of Kamoa-Kakula’s total concentrate production.

Kamoa-Kakula will also continue to toll-treat concentrates under a 10-year agreement with the Lualaba Copper Smelter (LCS), located approximately 50 kilometres from Kamoa-Kakula, near the town of Kolwezi. Approximately 180,000 tonnes of copper concentrate per year is toll-treated at LCS.

As a by-product, the smelter will also produce approximately 700,000 tonnes per year of high-strength sulphuric acid. There is a strong demand for sulphuric acid in the DRC, as it is used to leach copper from oxide ores through the SX-EW (solvent extraction and electrowinning) process.

In 2023, approximately 6 million tonnes of acid were consumed by mining operations in the DRC. Domestic acid demand is expected to increase to over 7 million tonnes in the short to medium term.

The market price for acid in the DRC is comparatively high, as most of the high-strength sulphuric acid consumed is imported first as sulphur, with high associated transportation costs, and burned in domestic acid plants to produce liquid high-strength sulphuric acid. Offtake contracts for the high-strength sulphuric acid produced by the smelter are well-advanced with local purchasers.

The on-site smelter will offer transformative financial benefits for the Kamoa-Kakula Copper Complex, most significantly a material reduction in logistics costs, and to a lesser extent reduced concentrate treatment charges and local taxes, as well as revenue from acid sales.

Logistics costs accounted for approximately one-third of Kamoa-Kakula’s total cash cost (C1) during 2024 to date, and the volume of required trucks is expected to approximately halve following the smelter start-up as each truck will transport 99+%-pure blister copper anodes instead of wet concentrate with 40-50% contained copper. Smelting on-site is expected to drive a decrease in average cash cost (C1) of approximately 20%.

Refurbishment of hydropower at Inga II approximately 70% complete, now on track for Q1 2025 completion

The refurbishment of Turbine #5 at the Inga II hydroelectric facility is approximately 70% complete and advancing within budget to generate 178 MW of hydroelectric power for the DRC grid from Q1 2025.

All critical-path equipment packages have now been delivered to the site, with all contractors fully mobilized and assembly work underway.

ProMarks and Trafigura sign MOU with the Angolan government to build a 2,000 MW high-voltage ‘interconnector’ to supply hydro-powered electricity in DRC and Zambia

On July 4, 2024, Trafigura Group of Geneva, Switzerland, and ProMarks of Luanda, Angola signed a Memorandum of Understanding (MOU) with the Government of Angola to study the technical and economic viability of building a 2,000 MW high-voltage electricity “interconnector” (a high-voltage direct current transmission line) to export surplus green electricity to the DRC Copperbelt and Zambia.

The project enables electricity generated by hydroelectric dams located in the north of Angola to be connected to the Southern Africa Power Pool, via the DRC.

A joint venture will be formed between ProMarks and Trafigura to develop, finance, construct and operate the electricity “interconnector”.

The project is intended to be financed through a combination of equity capital and third-party debt. Planning, approvals, and construction would take around four years after the final investment decision is made.

Basic engineering for ‘Project 95′ complete, aiming to increase copper recovery from Phase 1 and 2 concentrators to 95% over an 18-month execution timeline

Project 95 is an initiative targeting an increase in copper recoveries from current Phase 1 and 2 concentrator recovery rate of approximately 87% to a target of 95%.

There are over 20 million tonnes of tailings in the tailings storage facility at an estimated grade of over 0.75% copper. For comparison, the average head grade of the copper mines globally was approximately 0.63% copper in 2023, according to Bank of Montreal (BMO) research, see Figure 3. Following the full ramp-up of the Phase 3 concentrator, the quantity of tailings is expected to grow at approximately 13 million tonnes per annum, less the tailings used for backfill underground.

Figure 3. Global average copper head grade since 2000, compared with the estimated copper grade of Kamoa-Kakula’s tailings as at June 30, 2024.

Source: BMO Research, Wood Mackenzie

DRA Global of Johannesburg, South Africa was appointed to conduct basic engineering on Project 95, which was recently completed.

The modifications to the existing Phase 1 and 2 concentrators consist of a new coarse-fine cyclone bank, flash flotation cells, coarse rougher tailings tank, additional feed tanks to the rougher scavenger and cleaner scavenger flotation cells, and new cleaner flotation cells.

In addition, a new regrind milling plant adjacent to the Phase 1 and Phase 2 concentrator plants will be constructed, with high-intensity grinding (HIG) mills, rougher tailings cyclones, and slime thickeners.

The capital cost estimate for Project 95 includes $198 million for the required modifications to the Phase 1 and 2 concentrator plants.

The execution timeline is 18 months from the appointment of the engineering, procurement, and construction management (EPCM) contractor. Tendering of the EPCM contractor has already commenced, along with the procurement of long-lead order equipment items.

Following the completion of Project 95, the copper grade of the tailings stream from the Phase 1 and 2 concentrators will be significantly reduced to 0.2% copper.

To avoid sterilizing the higher-grade tailings currently in cell 1, tailings from Project 95 will be placed into a separate cell within the tailings storage facility, cell 2.

The construction of cell 2, originally intended to take place during the Phase 4 expansion, will be brought forwards to separate the existing high-grade tailings from the new lower-grade tailings produced by Project 95.

Construction of cell 2 is estimated at $102 million and will be constructed in parallel with the Project 95 concentrator modifications.

Geotechnical work has already commenced on cell 2, which will be a downstream-tailings design and comply with the Global Industry Standard on Tailings Management (GISTM).

The retreatment of the high-grade tailings in cell 1 to recover the copper, will then take place at the start of the Phase 4 expansion.

More information on the Phase 4 expansion and the Phase 3 debottlenecking program will be included in an updated Integrated Development Plan, which is expected to be completed by the end of the year.

Improving the recovery of the Phase 3 concentrator will take place as part of a Phase 3 debottlenecking program, a study that is expected to commence once the Phase 3 concentrator has reached steady state production.

Project 95 to unlock up to 30,000 tonnes per annum of additional copper growth for a capital investment of $198 million, delivering a capital intensity of ~$7,000/tonne

Project 95 is expected to increase Phase 1 and 2 concentrator’s annual copper production by up to 30,000 tonnes of copper per annum.

At a capital intensity of approximately $7,000 per tonne of copper produced, it is substantially lower than that of the copper industry average.

For context, according to recent BofA Securities research, dated July 12, 2024, the average capital intensity for greenfield copper projects and brownfield expansions is $20,000 per tonne and $17,500 per tonne, respectively, with recent copper projects executed at significantly higher capital intensity.

Project 95’s incremental operating costs are estimated to be approximately $4/t milled.

New in-country financing facilities to assist Kamoa-Kakula with funding future expansions, including Project 95

In the first half of 2024, Kamoa Copper closed a term facility of $400 million of financing with ABSA of Johannesburg, South Africa, Africa Finance Corporation (AFC) of Lagos, Nigeria, Rawbank of Kinshasa, DRC, and FirstBank of Lagos, Nigeria. $200 million was drawn under this facility in each of Q1 and Q2 2024.

The new funding facilities will be used to fund both the Phase 3 expansion of Kamoa-Kakula, as well as future growth, such as Project 95, and working capital.

This brings total Kamoa-Kakula joint-venture in-country term loans and working capital facilities to $800 million, at attractive interest rates of less than %.

COPPER PRODUCTION AND CASH COST GUIDANCE FOR 2024

| Kamoa-Kakula 2024 Guidance | |

| Contained copper in concentrate (tonnes) | 440,000 to 490,000 |

| Cash cost (C1) ($ per pound) | 1.50 to 1.70 |

The figures are on a 100% project basis and metal reported in concentrate is before refining losses or deductions associated with smelter terms.

Kamoa-Kakula’s 2024 guidance is based on several assumptions and estimates and involves estimates of known and unknown risks, uncertainties, and other factors that may cause the actual results to differ materially.

Production guidance is based on assumptions for the ramp-up of the Phase 3 concentrator, the reliability of the DRC grid power supply, and the availability of back-up generation capacity, among other variables.

The Kamoa-Kakula joint venture produced a total of 100,812 tonnes of copper in concentrate for the three months ended June 30, 2024, and 187,015 tonnes of copper for the first six months of 2024.

Cash cost (C1) per pound of payable copper amounted to $1.52/lb. for the three months ended June 30, 2024, and $1.54/lb. for the six months ended June 30, 2024.

Cash cost guidance is based on assumptions including copper ore grade processed, the ramp-up of the Phase 3 concentrator, reliability of DRC grid power supply, the availability and cost of alternative sources of electricity supply, and prevailing logistics rates among other variables.

Cash cost guidance is impacted by the timing of the ramp-up of Kamoa-Kakula’s Phase 3 concentrator. Copper in concentrate produced by the Phase 3 concentrator is expected to have a higher cash cost, compared with that of the Phase 1 and Phase 2 concentrators.

This is primarily due to the lower copper grade of the Kamoa 1 and Kamoa 2 underground mines that feed the Phase 3 concentrator, compared with the higher-grade Kakula Mine that feeds the Phase 1 and Phase 2 concentrators.

Completion of the on-site smelter construction, which is on target for construction completion by the end of 2024, is expected to drive a decrease in average cash cost (C1) over the first five years post-completion and ramp-up by approximately 20%.

Cash cost (C1) is a non-GAAP measure used by management to evaluate operating performance and includes all direct mining, processing, stockpile rehandling charges, and general and administrative costs.

Smelter charges and freight deductions on sales to the final port of destination (typically China), which are recognized as a component of sales revenues, are added to cash cost (C1) to arrive at an approximate cost of delivered finished metal.

2. Kipushi Project

68%-owned by Ivanhoe Mines

Democratic Republic of Congo

The historic Kipushi zinc-copper-germanium-silver mine in the DRC is adjacent to the town of Kipushi, approximately 30 kilometres southwest of Lubumbashi on the Central African Copperbelt. Kipushi is approximately 250 kilometres southeast of the Kamoa-Kakula Copper Complex and less than one kilometre from the Zambian border.

Ivanhoe acquired its 68% interest in the Kipushi Project in November 2011, through Kipushi Holding which is 100%-owned by Ivanhoe Mines.

The balance of 32% in the Kipushi Project is held by the DRC state-owned mining company, Gécamines. As per the updated joint venture agreement signed in late 2023, Gécamines’ ownership is set to increase to 38% upon completion of outstanding conditions precedent.

For over 69 years up until 1993 when the mine was placed on care and maintenance, the Kipushi Mine produced a total of 6.6 million tonnes of zinc and 4.0 million tonnes of copper from 60 million tonnes of ore grading 11% zinc and approximately 7% copper.

It also produced 278 tonnes of germanium and 12,673 tonnes of lead between 1956 and 1978. There is no formal record of the production of precious metals as the concentrate was shipped to Belgium and the recovery of precious metals remained undisclosed during the colonial era; however, drilling by Ivanhoe Mines has encountered significant silver values within Kipushi’s current zinc- and copper-rich deposits.

Since acquiring its interest in Kipushi in 2011, Ivanhoe’s drilling campaigns have upgraded and expanded the mine’s zinc-rich Big Zinc and Southern Zinc orebodies to a Measured and Indicated Mineral Resource of 11.78 million tonnes grading 35.34% zinc, 0.80% copper, 23 grams/tonne (g/t) silver and 64 g/t germanium, at a 7% zinc cut-off, containing 9.2 billion pounds of zinc, 8.7 million ounces of silver and 24.4 million ounces of germanium.

Kipushi’s exceptional zinc grade is more than twice that of the world’s next highest-grade zinc project, according to Wood Mackenzie, a leading, international industry research and consulting group.

Construction of Kipushi concentrator completed ahead of schedule, with, with ramp-up to steady-state operations underway during Q3

Construction of the new 800,000-tonne-per-annum concentrator facility was completed months ahead of schedule on May 31, 2024, following the first feed of ore. The concentrator process consists of dense media separation (DMS) and a milling and flotation circuit. Design recoveries are targeted to be 96% with a concentrate grade averaging 55% contained zinc. As per the 2022 Kipushi Feasibility study, released on February 14, 2022, over the first five years annualized production is expected to average 278,000 tonnes of zinc in concentrate, positioning Kipushi as the world’s fourth-largest zinc mine and the largest in the African continent. See Figure 4.

Figure 4. World’s top 10 zinc mines estimated for 2025, by paid zinc production per annum (‘000 tonnes) with head grade (% zinc).

Source: Wood Mackenzie, 2024, Ivanhoe Mines. Production and grade assumptions for Kipushi are the first five-year average as stated in the 2022 Feasibility Study.

Commissioning of the Kipushi concentrator commenced in early May, with first feed of ore from the surface ROM stockpiles fed through the ball mill during the evening of May 31, 2024.

The first batch of concentrate production was achieved on June 14, 2024. Ramp-up to steady-state production is ongoing and expected to be completed in September.

Basic engineering has commenced to increase zinc production, by optimising and de-bottlenecking the newly constructed Kipushi concentrator.

The de-bottlenecking program is targeting a 20% increase in processing capacity to 960,000 tonnes of ore per annum. There is sufficient capacity to also increase mining and hoisting rates to support an upsized concentrator throughput.

The de-bottlenecking program is expected to take approximately nine months, based on the availability of long-lead order equipment.

The construction of the down-stream tailings storage facility is complete and commissioned. The tailings storage facility has been designed per Global Industry Standards on Tailings Management (GISTM).

Off-take agreements for Kipushi concentrate signed, plus $170 million in financing facilities secured

Ivanhoe Mines recently established a wholly-owned subsidiary, Ivanhoe Marketing (Pty) Ltd (Ivanhoe Marketing), to manage the in-land logistics across the African continent.,

Ivanhoe Marketing will be responsible for arranging the transportation of zinc concentrate from mine gate to the point of delivery.

Initially, it is expected that approximately 50% of Kipushi’s concentrate will be delivered to Europe for smelting on a Cost, Insurance, and Freight (CIF) basis, exported via the port of Walvis Bay. The remaining 50% will be a Delivered at Place (DAP) to the port of Durban.

Ivanhoe Marketing has entered into off-take agreements with CITIC and Trafigura for the sale of Kipushi concentrate. To date, off-take agreements for approximately two-thirds of Kipushi’s zinc concentrate production over a five-year term have been agreed.

The off-take agreements contain standard, international commercial terms, including payables and treatment charges based on the zinc industry’s annual benchmark.

The 2024 annual treatment charge benchmark is currently $165 per tonne of concentrate. Given an international shortage of clean zinc concentrates to feed the world’s zinc smelters, the current spot rate for zinc treatment charges is significantly lower than the $165 per tonne benchmark rate. Off-take agreements for the remaining concentrate are expected to be placed in the coming months.

In addition to the off-take agreements, Trafigura and CITIC Metal have each provided a loan facility to KICO for $60 million over the term of the off-take contract, at a rate of interest SOFR, plus 6%.

Both these loan facilities were drawn in July 2024. A bank facility has also been signed and drawn with domestic lender FirstBank DRC for $50 million at SOFR plus 4.5%.

Run-of-mine stockpiles to support ramp-up to steady-state production, with mining rates to increase throughout the second half of 2024

As of June 30, 2024, a total of approximately 336,000 tonnes of ore at an average grade of 23.4% zinc are stored in surface ROM stockpiles adjacent to the Kipushi concentrator.

This includes approximately 150,000 tonnes of “high-grade” ore at an average grade of over 30% zinc. The stockpiled ore, which contains nearly 80,000 tonnes of zinc that is currently trading at approximately $3,000 per tonne, is now being used for the ongoing hot commissioning and ramp-up of the Kipushi concentrator.

Underground mining rates are expected to significantly increase throughout the second half of the year to match the steady-state processing rate of the Kipushi concentrator.

Year-to-date underground mining rates have averaged just over 20,000 tonnes per month, with rates expected to increase to 75,000 tonnes per month, at an average grade of up to 40% zinc, by year-end.

Updated greenhouse gas emissions assessment confirms that Kipushi will be lowest carbon emitter per unit of zinc production in the world

Kipushi will be the lowest greenhouse gas emitter per tonne of zinc produced. On a Scope 1 and 2 basis (reported from ore to mine gate), Kipushi’s greenhouse gas (GHG) emissions intensity for 2025 is expected to be 0.019 equivalent tonnes of carbon dioxide per tonne of contained zinc produced (t CO2-e / t Zn). This comfortably ranks Kipushi near the bottom of the Scope 1 and 2 GHG emissions curve, as shown in Figure 5.

This is partially due to the ultra-high-grade Big Zinc orebody, which has an average head grade of over 36% zinc over the first five years of operation. The Kipushi head grade is more than 6.5 times higher than the average head grade of the top 20 zinc mining operations in 2023. A high head grade means significantly less rock is mined, hauled, and milled for the same tonne of zinc produced. The total peak power required by the mining and milling operation is 23 MW.

The low carbon emissions intensity is also a function of the DRC grid being among the world’s cleanest, with 99.5% of grid power generated from hydroelectricity, according to the U.S. Energy Information Administration.

Figure 5. 2023 Scope 1 & 2 zinc GHG emissions intensity curve, highlighting Kipushi and the top 10 largest zinc mining operations in 2023.

Notes: Kipushi and industry peer Scope 1 and 2 GHG emissions data are estimates by Skarn Associates. Estimates include all direct and indirect emissions to produce contained zinc from ore to mine gate. The horizontal width of each bar represents the quantity of each operation’s 2023 zinc production in ‘000 tonnes. 2025 Kipushi production is estimated to be 278,000 tonnes of payable zinc in concentrate, based on the 2022 feasibility study. 2025 zinc production is not forward guidance. It is estimated that operations will emit a total of 5,047 equivalent tonnes of CO2, thereby producing 0.019 equivalent tonnes of CO2 per tonne of zinc produced. Chart sources: Skarn Associates, Ivanhoe Mines.

ZINC PRODUCTION AND CASH COST GUIDANCE FOR 2024

| Contained zinc in concentrate (tonnes) | 100,000 to 140,000 | ||

These figures are on a 100% project basis and metal reported in concentrate is before treatment losses or payability deductions associated with smelter terms.

Kipushi’s 2024 production guidance is based on several assumptions and estimates, including among other things, assumptions about the timing of ramp-up of the new 800,000-tonne-per-annum Kipushi concentrator. Guidance involves estimates of known and unknown risks, uncertainties, and other factors that may cause the actual results to differ materially.

The Company will provide 2024 guidance ranges for C1 cash cost (C1) per pound of payable zinc once ramp-up to steady-state production has been achieved.

3. Platreef Project

64%-owned by Ivanhoe Mines

South Africa

The Platreef Project is owned by Ivanplats (Pty) Ltd (Ivanplats), which is 64%-owned by Ivanhoe Mines. A 26% interest is held by Ivanplats’ historically disadvantaged, broad-based, black economic empowerment (B-BBEE) partners, which include 20 local host communities with approximately 150,000 people, project employees, and local entrepreneurs.

A Japanese consortium of ITOCHU Corporation, Japan Oil, Gas and Metals National Corporation (JOGMEC), and Japan Gas Corporation, owns a 10% interest in Ivanplats, which it acquired in two tranches for a total investment of $290 million.

The Platreef Project hosts an underground deposit of thick, platinum-group metals, nickel, copper, and gold mineralization on the Northern Limb of the Bushveld Igneous Complex in Limpopo Province – approximately 280 kilometres northeast of Johannesburg and eight kilometres from the town of Mokopane in South Africa.

On the Northern Limb, platinum-group metals mineralization is primarily hosted within the Platreef, a mineralized sequence traced for more than 30 kilometres along strike.

Ivanhoe’s Platreef Project, within the Platreef’s southern sector, is comprised of two contiguous properties: Turfspruit and Macalacaskop.

Turfspruit, the northernmost property, is contiguous with, and along strike from, Anglo Platinum’s Mogalakwena group of mining operations and properties.

Since 2007, Ivanhoe has focused its exploration and development activities on defining and advancing the down-dip extension of its original discovery at Platreef, now known as the Flatreef Deposit, which is amenable to highly mechanized, underground mining methods.

Construction of Phase 1 concentrator completed on-schedule, with first ore deferred until 2025; underground development prioritizing waste development required to accelerate start of Phase 2

Construction of Platreef’s Phase 1 concentrator was completed on-schedule after the quarter end. Cold commissioning started in July, with water being fed through the concentrator.

The concentrator will be placed on care and maintenance until H2 2025, as Shaft #1 prioritizes hoisting waste development required to bring forward the start of Phase 2.

Optimized Platreef development plan to accelerate and re-scope Phase 2 to 4-Mtpa capacity by equipping Shaft 3 for hoisting

In 2023, Ivanhoe’s engineering team completed an internal optimization study of the phased expansion of the Platreef Project. Current underground development and operations are dependent on the initial 1 Mtpa Shaft #1 until the 10-metre-diameter, 8-Mtpa Shaft #2 is commissioned. The study concluded that accelerating the startup of Phase 2 will create significant project value.

Phase 2 expansion will be accelerated by re-purposing ventilation Shaft #3 for hoisting. Shaft #3 will generate additional hoisting capacity of approximately 4 Mtpa, bringing total hoisting capacity to approximately 5 Mtpa.

The reaming of Shaft #3 down to the 950-metre level commenced in 2023. Reaming is the process of boring, or excavating, a vertical shaft from the bottom up and it is the quickest and safest method of constructing a shaft.

Reaming is expected to be completed during the third quarter of 2024. Once equipped, Shaft #3 is expected to be ready for hoisting in the first quarter of 2026, well ahead of the completion of the much larger Shaft #2.

The internal study concluded that equipping Shaft #3 for hoisting de-risks Phase 1 underground operations ahead of the completion of Shaft #2 and accelerates the underground development for Phase 2.

In addition, the Phase 2 concentrator would have an increased processing capacity of 3.3 Mtpa, up from 2.2 Mtpa as per the first module of Phase 2 defined in the Platreef 2022 Feasibility Study.

Therefore, the Phase 1 and Phase 2 concentrators will have a total combined processing capacity of approximately 4.0 Mtpa, with ore fed by Shaft #1 and Shaft #3.

Additional underground ventilation will now be provided by a new 5.1-metre diameter shaft, named Shaft #4. The drilling of the pilot hole for Shaft #4 commenced in April 2024.

Once reaming is complete and the ventilation fans are installed, Shaft #4 is expected to be operational during the third quarter of 2025.

Following the completion of the optimization study, work is well underway on an updated independent Feasibility Study for the Phase 2 expansion, which is planned to be completed in the fourth quarter of 2024.

Study work in progress for new Phase 3 expansion to 10 Mtpa, expected to rank Platreef as one of the world’s largest PGM producers

In parallel with the release of the updated Phase 2 Feasibility Study, Ivanhoe also commissioned a preliminary economic assessment (PEA) for an additional expansion, Phase 3, taking the total Platreef processing capacity up to approximately 10 Mtpa.

The new Phase 3 expansion is expected to consist of two additional 3.3-Mtpa concentrator modules, to be located adjacent to the Phase 1 and 2 concentrators.

Phase 3 is anticipated to rank Platreef as one of the world’s largest and lowest-cost platinum-group metal, nickel, copper, and gold producers.

The 10-Mtpa concentrator capacity of the Phase 3 expansion will be 12.5 times greater than that of Phase 1 and 2.5 times greater than the processing capacity of the optimized Phase 2 expansion.

The completion of Shaft #2 will increase the total hoisting capacity for ore and waste development, across all three shafts to over 12 Mtpa.

Construction of Shaft #2 headgear approximately 60% complete

Construction activities are advancing well on the installation of 1,124 tonnes of internal structural steel inside Shaft #2’s headgear. I

n addition, all long-lead order equipment packages for the headgear have now been placed. The installation of the sinking winders and related infrastructure is advancing well with the on-boarding of the sinking contractor to commence sinking operations in the first quarter of 2025.

The production winder, as well as the man and material winder, are expected to be delivered to site early in the third quarter of 2024.

4. Western Foreland Exploration Project

60%- to 100%-owned by Ivanhoe Mines

Democratic Republic of Congo

Ivanhoe’s DRC exploration group is targeting Kamoa-Kakula-style copper mineralization on its Western Forelands exploration licences.

The 21 licences in the Western Foreland cover a combined area of approximately 1,808 square kilometres to the north, south, and west of the Kamoa-Kakula Copper Complex.

The exploration group is using models that successfully led to the discoveries of Kakula, Kakula West, and the Kamoa North Bonanza Zone at the Kamoa-Kakula Copper Complex.

More recent discoveries at Makoko, Kiala, and the 2023 Kitoko mineralization confirm the effectiveness of these models.

The total area of the land package has been reduced from 2,407 square kilometres in accordance with DRC regulations, as 10 exploration licences reached the end of their first holding period, requiring a relinquishment of 50% of overall size. Four of the licences are under an earn-in right to increase Ivanhoe ownership by funding ongoing exploration activities.

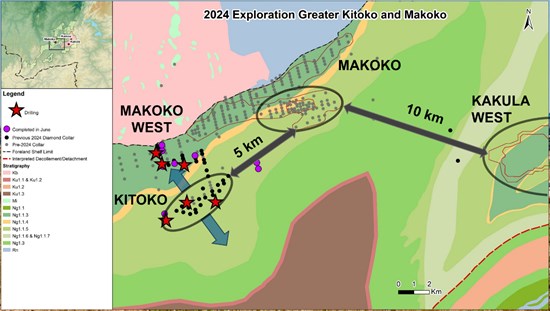

Diamond drilling during the second quarter of 2024 has been focused on Makoko West and Kitoko with one hole drilled in Lubudi.

Nine contractor rigs were in operation at quarter end, having completed a total of 20,701 metres of diamond core drilling, over 27 completed holes, and two abandoned holes.

Drilling activity at Kitoko continues to define the extent of mineralization and test the extent of the system. Between three and four diamond drill rigs were active on the prospect during the quarter, with nine holes completed.

Two holes were abandoned due to broken ground. Kitoko mineralization is now interpreted to occur at the onlap of pyritic layers of Nguba Group diamictites and siltstones with a Kibaran age basement high.

The high-grade onlap zones are still open at depth and will be one of the areas targeted to be drilled in the coming months. Step-out drilling continues on 400-meter sections.

Drilling at Makoko West (southwest of the original Makoko mineral resource declared in 2023) continued during the quarter with up to four rigs in operation.

The drilling at Makoko West is targeting the up-dip area of the Kitoko mineralized system. Fifteen holes were completed, with three underway at quarter end.

Drilling activities also started in June on the area between Kitoko and Makoko to characterize the basement architecture in the areas and to test for sub-basins (see Figure 7). The drilling in this untested region will continue for the remainder of the dry season.

Figure 7. Map showing location of current drilling activities of six out of the nine rigs current drilling in the Western Forelands. Drilling is primarily focused around Makoko West and Kitoko, as well as testing mineralization between the two areas.

Drilling has also started in the Lubudi region to the south of the Western Forelands. Drilling in this area was not previously focused on the deeper part of the shelf due to a lack of Roan sediments, which before the Kitoko discovery were thought to be essential conditions for high-grade copper mineralization.

The Kitoko discovery, however, proved that Roan sediments are not necessarily required and therefore Lubudi is being tested again, only this time at greater depths.

A passive seismic program initially scheduled for the second quarter of 2024 at both Lupemba and Kitoko will now take place in the third quarter.

The passive seismic program will test the system’s ability to determine the thickness of Kalahari sand, basement architecture, and the location of thick mafic rocks below Nguba sediments.

A shallow, air-core drilling program through the Kalahari sand cover, designed to collect samples at the top of the underlying residual soil, commenced in early July. This program is expected to run through the remainder of the dry season.

5. The Mokopane Feeder Exploration Project

100%-owned by Ivanhoe Mines

South Africa

Three new 100%-owned exploration rights were granted on the Northern Limb of the Bushveld complex in South Africa during Q4 2022.

The three new exploration rights (Blinkwater 244KR, Moordrift 289KR and Lisbon 288KR) cover 80 square kilometres forming a continuous block situated on the southwest border of the existing Platreef Project’s mining rights.

A gravity-high anomaly based on wide-spaced historical Council for Geoscience data was interpreted to represent a primary feeder zone to the Rustenburg Layered Suite of the Northern Limb of the Bushveld Complex.

The working hypothesis for this large gravity anomaly (the Mokopane Feeder) is that it represents a significant thickening of the Rustenburg Layered Suite, particularly of the denser Lower Zone units associated with regional scale crustal faults, with significant potential for nickel, copper and platinum-group metals mineralization.

Detailed high-resolution fixed-wing airborne magnetic and Falcon airborne gravity gradiometer geophysical surveys were completed in 2023 to map the subsurface petrophysical characteristics of the anomaly. Detailed inversion modeling of the two high-resolution datasets was completed in December 2023.

The collection, interpretation and review process of all geological and geophysical data is now complete. The geological understanding of the anomaly continues to evolve, with three targets identified for drilling.

The drilling program is expected to commence towards the end of Q3 2024, once the stakeholder engagement and heritage impact assessment are complete.Copper Complex.

![]()