Ivanhoe Mines reports Q1 2023 Copper production from Kamoa-Kakula Copper Complex

■Kamoa-Kakula produced record 34,915 tonnes of copper in March

■Kamoa-Kakula reported weekly production record of 9,016 tonnes of copper and daily production record of 1,563 tonnes

of copper in March

■Phase 1 and 2 concentrators reached new daily average milling record of over 29,000 tonnes

■Kamoa-Kakula achieved record average copper recoveries exceeding 88% in March

■Kamoa-Kakula milled approximately 1.93 million tonnes of ore during the quarter at average grade of 5.4% copper

■Ivanhoe Mines to issue sixth annual Sustainability Report on April 13, highlighting the company’s commitment to

mining with a greater purpose

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN;OTCQX: IVPAF) Executive Co-Chair Robert Friedland and President Marna Cloete are pleased to announce that the Kamoa-Kakula Copper Complex in the Democratic Republic of Congo (DRC) produced 93,603 tonnes of copper in concentrate during the first quarter of 2023. The Phase 1 and 2 concentrators are now regularly operating at the increased processing rate of 9.2 million tonnes per annum (Mtpa), following the completion

of the debottlenecking program.

The $50-million Phase 1 and 2 concentrator debottlenecking program was completed on-budget and ahead of schedule in late February, increasing production capacity up to 450,000 tonnes of copper in concentrate per annum. Following the completion of the debottlenecking, Kamoa-Kakula’s Phase 1 and 2 concentrators had a record-breaking March.

A production record of 34,915 tonnes of copper in concentrate was achieved during the month, in addition to a weekly production record of 9,016 tonnes in mid-March, and a daily production record of 1,563 tonnes on March 25.

These records were achieved following two scheduled plant shutdowns during the first quarter to tie in the new debottlenecking equipment.

Kamoa-Kakula’s Phase 1 and 2 concentrators milled approximately 1.93 million tonnes of ore during the first quarter at an average feed grade of 5.4% copper.This included approximately 255,000 tonnes of ore from the surface stockpiles.

The Phase 1 and Phase 2 concentrators also substantially outperformed design specifications in terms of copper recovery during the month, with copper recoveries averaging 88.3% and periodically achieving 90%, significantly above Kamoa-Kakula’s nameplate 86% recovery rate.

The record monthly production in March was also achieved despite previously reported instability within the DRC’s southern power grid. Ivanhoe Mines maintains its 2023 annual production guidance for Kamoa-Kakula at between 390,000 to 430,000 tonnes of copper in concentrate.

Ivanhoe Mines’ Founder and Executive Co-Chairman, Robert Friedland commented:

“The operating performance at Kamoa-Kakula continues to impress as the team focuses on optimizing the concentrator plant following the successful completion of the Phase 1 and Phase 2 debottlenecking program, once again ahead of schedule and on budget, during the first quarter.

We’re particularly excited about the improving trends in copper recovery, which saw the concentrator plants operating at recoveries as high as 90% in March … driving record production numbers into the end of the month. “With the Phase 3 expansion well on track for 2024, Kamoa-Kakula represents a truly rare, high-margin growth story across the copper industry. Kamoa-Kakula is one of the world’s largest, highest-grade copper complexes, and a major economic engine that generates leading returns on capital and exceptional free cash flow.

As the rainy season in the Democratic Republic of Congo ends our geological team will also be ramping up exploration activities on Ivanhoe’s 90-100%-owned Western Foreland Exploration Project next door, where we expect to drill around 75,000 metres this year. We’re looking forward to the many successes to come with our partners and shareholders in 2023 and beyond.”

All figures are on a 100% project basis and metal reported in concentrate is before refining losses or deductions associated with smelter terms. Kamoa-Kakula produced 93,603 tonnes of copper during the first quarter of 2023, compared to 92,761 tonnes of copper in the fourth quarter of 2022. Ivanhoe Mines announced the ahead-of-schedule and on-budget completion of

Kamoa-Kakula’s Phase 1 and Phase 2 debottlenecking program on February 27,2023

The debottlenecking program increased the nameplate ore processing capacity by 22% from 7.6 to 9.2 million tonnes of ore per annum, increasing production capacity up to approximately 450,000 tonnes per annum of copper in concentrate.

Following the subsequent ramp-up, several operational records were achieved during March, including a record daily milling rate of 29,003 dry metric tonnes on March 18; a record daily production rate of 1,563 tonnes of copper on March 25; a weekly production record of 9,016 tonnes of copper between March 24 and 30; and a monthly production record of 34,915 tonnes of copper in concentrate.

Two scheduled plant shutdowns were completed during the first quarter to tie in the new debottlenecking equipment. The shutdown of the Phase 1 concentrator took place in late January 2023, and the shutdown of the Phase 2 concentrator plant was completed in late February 2023.

The new debottlenecking equipment consists of new hydrocyclones, new scavenger-cleaner flotation cells, a new concentrate thickener and a new Larox filter press, as well as upsized piping and pumping capacity.

The Phase 1 concentrator started operating at its new, sustained nameplate capacity of 580 dry tonnes per hour on January 25, 2023. On February 25, 2023, within 12 hours of restarting, the Phase 2 concentrator also ramped up to its new, sustained nameplate capacity of 580 dry tonnes per hour.

Thereby, achieving the targeted combined throughput of 9.2 million tonnes per annum. Subsequently, both concentrators have been able to deliver, over limited periods, in excess of 600 dry tonnes per hour.

Kamoa-Kakula milled approximately 1.93 million tonnes of ore during the first quarter at an average feed grade of 5.4% copper. While the ongoing expansion of underground infrastructure at the Kakula Mine takes place, ore continues to be drawn as required from surface stockpile to maximize copper production.

Kamoa-Kakula’s high- and medium-grade ore surface stockpiles totaled approximately 4.2 million tonnes at an estimated grade of 3.9% copper as of the end of March 2023.

The operation mined 2.0 million tonnes of ore grading 5.2% copper in Q1 2023, which was comprised of 1.8 million tonnes grading 5.6% copper from the Kakula mine, including 0.8 million tonnes grading 6.7% copper from the mine’s high-grade centre. (L-R) Rachelle Museka, Mill Operator; Linda Malumda, Senior Larox Filter Operator and Fancy Katuma, Sand Filter Operator standing in front the debottlenecked Phase 2 concentrator.

The additional Larox filter capacity, as part of the debottlenecking program, increases Kamoa-Kakula’s production capacity up to 450,000 tonnes per annum.

Copper recoveries from the Phase 1 and Phase 2 concentrators also improved during the quarter. The average recovery rate for the quarter was approximately 87%; however, concentrator recoveries in late March averaged 88.3% and periodically reached 90%, well above Kamoa-Kakula’s 86% design rate.

The Kamoa Copper process engineering team, together with several internationally recognized external metallurgy specialists, continue to investigate the feasibility of new technologies to further increase overall processing recoveries.

The recently commissioned concentrate thickener that was constructed as part of the debottlenecking program, was completed ahead-of-schedule and on-budget in late February. Kamoa-Kakula’s Phase 1 and 2 concentrators set a monthly production record of 34,915 tonnes of copper in concentrate during March 2023.

Kamoa-Kakula is working closely with the DRC’s state-owned power utility, La Société Nationale d’Electricité (SNEL) in identifying potential improvements to the regional grid infrastructure. Kamoa-Kakula is also assisting with the delivery of

these improvements.

In addition, Kamoa Copper is independently installing sufficient redundancy to isolate Kamoa-Kakula’s Phases 1, 2 and 3 operations from any potential future power intermittencies. In the near term, a phased increase of on-site, installed backup generation capacity is planned, from 32 megawatts (MW) to 132 MW.

An additional 11 MW is expected to be commissioned in the second quarter, with a further 73 MW to be installed towards the end of 2023. Concurrently, discussions are advancing to secure additional power via the Zambian interconnector. Longer term, the total power redundancy capacity is expected to be up to 200MW.

Surface earthworks for Phase 3 concentrator plant and associated infrastructure well advanced, with first flotation cells delivered in March Kamoa-Kakula’s Phase 3 expansion will consist of two new underground mines known as Kamoa 1 and Kamoa 2, located approximately 10 kilometres north of the existing Kakula underground mine, and the Phase 1 and Phase 2

concentrators.

A new, 5-million-tonne-per-annum concentrator is under construction adjacent to the new Kamoa mines, which are also under development. The concrete foundations under construction for the Phase 3 concentrator flotation cells. Construction of Phase 3 concentrator is advancing on schedule.

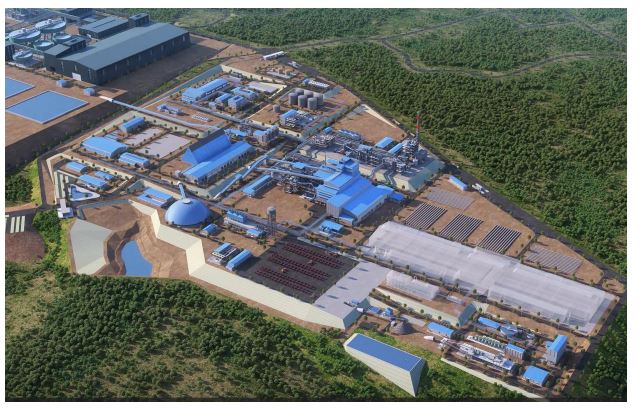

3D rendering of the furnace and off-gas handling building (RHS), and acid production facility (LHS). All smelter off-gas streams, including the acid plant tail gas, will be treated through the de-sulphurisation plant. The plant will produce 650,000 to 800,000 tonnes of high-strength sulphuric acid per annum, which will be sold domestically within the DRC Copperbelt.

Construction activities on the direct-to-blister flash copper smelter are advancing on schedule and are approximately 36% complete. Earthworks are 100% complete and civil works now well underway.

The direct-to-blister and electric slagcleaning furnaces foundation construction is complete, with structural steel installation having commenced in March. Foundation construction for the smelting building, as well as the anode-refining furnace building are also principally complete.

The smelter site is adjacent to Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants and will be fed by a mix of copper concentrate produced from Phase 1, 2 and 3 concentrators. 3D rendering of the 100-hectare smelter project site.

The smelter will be constructed to meet the highest environmental and safety standards, as set by the International Finance Corporation (IFC) Performance Standards and the World Bank Group Environmental Health and Safety (EHS) Guidelines.

![]()