Kamoa Copper reports record quarterly production of 87,314 tonnes of copper in Q2 2022

Kamoa Copper reports record quarterly production of 87,314 tonnes of copper in Q2 2022

Kamoa-Kakula produces record 30,379 tonnes of copper in June, Phase 2 achieves steady-state production at the end of May

Ivanhoe Mines joins United Nations Global Compact, the largest corporate sustainability initiative in the world

Basic engineering complete for Kamoa Copper’s Phase 3 direct-to-blister flash smelter; orders for long-lead time equipment underway

Ivanhoe Mines to issue Q2 2022 financial results and host conference call for investors on August 15

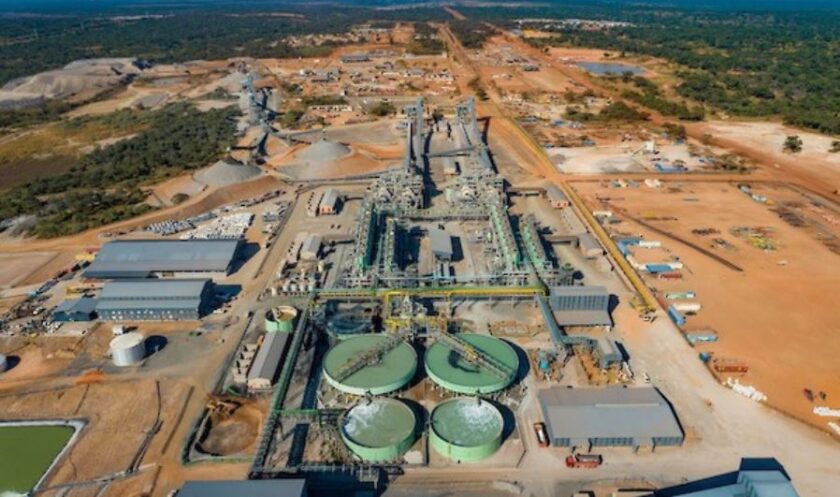

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that the Kamoa-Kakula Mining Complex in the Democratic Republic of Congo has set a new quarterly production record in the second quarter of 2022, with 87,314 tonnes of copper in concentrate produced.

Kamoa-Kakula’s Phase 1 and Phase 2 3.8-million-tonne-per-annum concentrator plants produced 30,379 tonnes of copper in concentrate during June 2022. This performance marks the third consecutive month that Kamoa-Kakula has surpassed its throughput design capacity of 7.6 million tonnes per annum, following the commissioning of Phase 2.

Kamoa Copper milled approximately 1.95 million ore tonnes during the second quarter at an average feed grade of 5.44% copper. Copper recoveries were averaging more than 86% during June 2022, with feed grades averaging approximately 5.5% copper.

Ongoing mining optimization work at the Kakula Mine is targeting improved head grade during the second half of 2022 towards 6% copper. Kamoa Copper is also evaluating additional material handling capacity at Kakula to increase mining rates to feed the de-bottlenecked Phase 1 and 2 processing capacity of 9.2 million tonnes per year, which will be incorporated into the Phase 3 expansion Pre-Feasibility Study scheduled for release in the second half of 2022.

The Phase 1 and Phase 2 concentrator plants are approaching a combined annualized production rate of approximately 400,000 tonnes of copper in concentrate. The de-bottlenecking program is on track to boost Kamoa Copper’s annual production to approximately 450,000 tonnes of copper in concentrate per year by the second quarter of 2023.

Management anticipates that the early commissioning of the Phase 2 concentrator plant in March 2022, approximately four months ahead of schedule, will enable Kamoa Copper to deliver in the upper range of its 2022 production guidance of 290,000 to 340,000 tonnes of copper in concentrate.

Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants produced a record 30,379 tonnes of copper in June 2022. Kamoa Copper is approaching a copper production rate of 400,000 tonnes per year.

Mr. Friedland commented: “Kamoa Copper continues to deliver industry-leading operational performance with the rapid advancement of Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants, which now are approaching a production rate of 400,000 tonnes copper per year. We will continue this track record of excellence as we realize the vast potential across the Kamoa-Kakula Mining Complex, which will be operating in the Democratic Republic of Congo for generations.

“Kamoa-Kakula is on pace to be the world’s third-largest copper mining complex by the end of 2024, with the Phase 3 expansion expected to boost total copper production to approximately 600,000 tonnes per annum. We are already among the ranks of the world’s major copper producers … a metal the world vitally requires for conventional energy and industry, as well as the long-term shift to green energy and electrification. We are at an inflection point for the copper industry … one where we must meet substantial demand growth over the coming decades, even as discovering and building new mines has become more challenging and more complex.

“The supply-demand landscape for the copper market remains extremely clear despite any short-term market fluctuations and policy-driven demand destruction. Kamoa-Kakula will be an integral part of the supply solution, but we will need astronomically higher global copper production to solve the ongoing energy crisis and complete the vital transition to green energy.”

Watch Mr. Friedland’s June 2022 exclusive, long-form keynote discussion at the Bank of America’s Commodity Conference: https://bit.ly/3AnJbrw

The Phase 1 and Phase 2 plants milled 1.95 million ore tonnes during the second quarter at an average feed grade of 5.44% copper.

Construction to increase concentrate thickener capacity is ongoing as part of the Phase 1 and Phase 2 debottlenecking program.

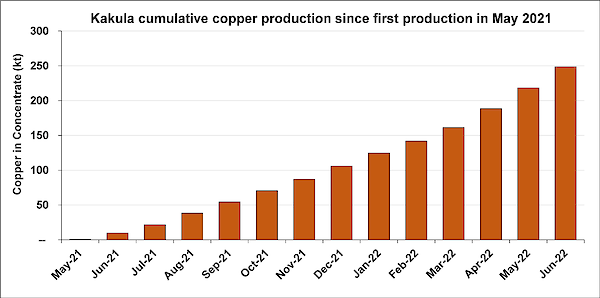

Figure 1: Monthly Kakula cumulative copper production – total production of approximately 250,000 tonnes copper from May 2021 to June 30, 2022.

Kamoa-Kakula reports record quarterly production of 87,314 tonnes copper following achievement of Phase 2 steady-state operations

In late March 2022, Ivanhoe Mines announced that Kamoa-Kakula’s Phase 2 concentrator plant began hot commissioning significantly ahead of schedule. First ore was introduced into the Phase 2 milling circuit on March 21, 2022, and first copper concentrate produced approximately four months ahead of the originally announced development schedule. Commercial production from the Phase 2 concentrator was declared on April 7, 2022, while steady state production was achieved at the end of May 2022.

Kamoa-Kakula has milled approximately three million tonnes of ore at an average feed grade of 5.74% copper year-to-date, and produced approximately 143,000 tonnes of copper in concentrate over the first half of 2022.

Kamoa Copper’s previously announced de-bottlenecking program also is progressing on schedule to increase the combined design processing capacity of the Phase 1 and Phase 2 concentrator plants to approximately 9.2 million tonnes per annum.

After successfully operating the Phase 1 concentrator, the Kamoa-Kakula team identified several relatively minor modifications that are expected to increase ore throughput from the current design of 475 tonnes per hour to approximately 580 tonnes per hour. These modifications include increasing the diameter of several pipes, replacing a number of motors and pumps with larger ones and installing additional flotation, concentrate-thickening, concentrate-filtration and tailings-disposal capacity.

Once completed in the second quarter of 2023, the de-bottlenecking program will enable the copper production from Kamoa-Kakula’s first two phases to reach approximately 450,000 tonnes per year, positioning Kamoa Copper as the world’s fourth largest copper producer.

Kamoa-Kakula’s Phase 1 and Phase 2 plants are undergoing a debottlenecking program to boost combined ore throughput to 9.2 million tonnes per annum by Q2 2023. Excavation is in progress to upgrade scavenger cleaner flotation capacity.

Kamoa 1 and Kamoa 2 box cut and decline ramp nearing completion, Phase 3 twin decline excavation progressing well

The Pre-Feasibility Study for the Phase 3 expansion is expected to be announced during the fourth quarter of this year. Kamoa-Kakula’s Phase 3 will consist of two new mines known as Kamoa 1 and Kamoa 2, as well as the initial decline development at Kakula West. A new, 5-million-tonne-per-annum concentrator plant will also be established adjacent to the two new mines at Kamoa. The associated power and surface infrastructure for Phase 3 will be designed to support future expansions.

Construction is nearing completion on the Phase 3 box cut and decline ramp at the Kamoa 1 and Kamoa 2 mines, while excavation of the twin declines to access Phase 3 mining areas also is advancing well. Construction works for the ramp, cut-off drains, and water-collection sumps are well advanced.

Basic engineering design for the Phase 3, 5-million-tonne-per-annum concentrator plant is nearing completion with procurement activities underway. During June, orders were placed for the following long-lead items: ball mills, concentrate filters, cone crushers and flotation cells. The earthworks contract is scheduled to be issued imminently.

Upon commencement of Phase 3 production, Kamoa Copper will have a total processing capacity of greater than 14 million tonnes per annum. Phase 3 is expected to increase copper production capacity to approximately 600,000 tonnes per year, with commissioning expected by the fourth quarter of 2024. This production rate will position Kamoa Copper as the world’s third-largest copper mining complex, and the largest copper mining complex on the African continent.

Construction works for the ramp, cut-off drains, and water-collection sumps is well advanced at the Kamoa 1 and Kamoa 2 box cut.

Excavation of twin declines at the Kamoa 1 and Kamoa 2 mines will provide access to the main Phase 3 mining areas.

Gracia Maseka, General Worker; Kamin Hortense, Dump Truck Operator; standing at the portal entrance to the twin Kamoa 1 and 2 declines.

Basic engineering complete and initial long-lead equipment ordered for Kamoa Copper’s direct-to-blister flash smelter

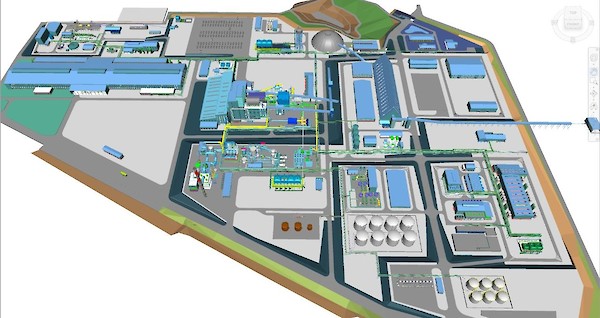

Kamoa-Kakula’s Phase 3 expansion includes a 500,000-tonne-per-annum, direct-to-blister flash smelter to produce approximately 99% copper metal, and the replacement of Turbine #5 at the Inga 2 hydroelectric power station. The turbine replacement will supply an additional 178-megwatts of clean hydroelectric power to the national grid.

Earthworks excavation is progressing well at the smelter site, adjacent to Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants, with bush clearing and top-soil stripping well advanced.

In June, Kamoa Copper placed purchase orders for the smelter’s slag cleaning furnace, anode refining furnaces and electrostatic precipitators, while basic engineering on the smelter design has been completed.

The Kamoa-Kakula smelter is designed to use technology supplied by Metso Outotec of Espoo, Finland, and to meet the International Finance Corporation’s (IFC) emissions standards. The smelter has been sized to process most of the copper concentrate forecast to be produced by Kamoa-Kakula’s Phase 1, Phase 2 and Phase 3 concentrators.

Construction and earthworks at the smelter site, adjacent to Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants.

Kamoa-Kakula’s smelter (3-D rendering below) uses technology supplied by Metso Outotec, with a production capacity of 500,000 tonnes per annum of approximately 99%-pure blister copper.

In late 2021, Kamoa Copper awarded China Nerin Engineering Co., Ltd. (Nerin) of Jiangxi, China, with the basic engineering contract for the planned, direct-to-blister flash smelter. Nerin is an international engineering company with more than 60 years of experience in smelter engineering and construction projects globally. Nerin actively promotes the advancement of smelting technology through its own research and development, and by establishing various partnerships with global industry peers, including Metso Outotec.

Ivanhoe Mines joins United Nations Global Compact, the largest corporate sustainability initiative in the world

Ivanhoe Mines is pleased to join the United Nations Global Compact (UNGC) initiative — a voluntary leadership platform for the development, implementation, and disclosure of responsible business practices.

Launched in 2000, the UN Global Compact is the largest corporate sustainability initiative in the world, with more than 14,000 companies in over 160 countries participating, the UNGC holds signatories and participants to the highest sustainability standards.

The multi-year strategy of the UN Global Compact is to drive business awareness and action in support of achieving the UN’s Sustainable Development Goals by 2030.

Ivanhoe Mines founded the Sustainable Livelihoods Program in 2010 to strengthen food security and farming capacity in the host communities near Kamoa‑Kakula by establishing an agricultural demonstration garden to support farmers at community level.

Today, approximately 900 community farmers are benefiting from the Sustainable Livelihoods Program, producing high‑quality food for their families and local communities. The program commenced with maize and vegetable production, and now produces many high-value crops, including fruit, aquaculture, poultry and honey. The construction of 100 new fishponds was completed in 2021, bringing the total number of fishponds to 138. The project will significantly contribute to local entrepreneurship and enhanced regional food security.

Fabrice Mazeze (centre), Kamoa-Kakula Sustainable Livelihoods Agronomist, assists community farmers with the corn harvest.

The construction of 100 new fishponds was completed in 2021, bringing the total number of fishponds at Kamoa-Kakula to 138.

Ivanhoe Mines to issue Q2 2022 financial results and host conference call for investors on August 15

Ivanhoe Mines will report its Q2 2022 financial results, and a detailed update on its operations, before market open on Monday, August 15, 2022.

The company will hold an investor conference call to discuss the Q2 2022 financial results at 10:30 a.m. Eastern time / 7:30 a.m. Pacific time on the same day. The conference call dial-in is +1-647-484-0258 or toll free 1-800-289-0720, quote “Ivanhoe Mines Q2 2022 Financial Results” if requested. Media are invited to attend on a listen-only basis.

81 total views , 1 views today