Kamoa Copper to Expand Processing Capacity of Phase 1 and Phase 2 Concentrators to 9.2 Million Tonnes of Ore per Year

Copper production from the first Kamoa Copper’s two phases projected to exceed 450,000 tonnes per year by Q2 2023, positioning Kamoa Copper as the world’s fourth largest copper producer

Kolwezi, Democratic Republic of Congo–(Newsfile Corp. – February 22, 2022) – Ivanhoe Mines (TSX: IVN) (OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun announced that Kamoa Copper has approved a de-bottlenecking plan for Kamoa-Kakula to increase the combined design processing capacity of the Phase 1 and Phase 2 concentrator plants by approximately 21%, to 9.2 million tonnes of ore per year (Mtpa), up from 7.6 Mtpa, once steady-state production is achieved at both concentrators.

The de-bottlenecking initiative is expected to increase Kamoa-Kakula’s Phase 1 and Phase 2 annual copper output to more than 450,000 tonnes by Q2 2023 ─ positioning Kamoa-Kakula as the world’s fourth largest copper producer.

Mark Farren, Kamoa Copper’s CEO, said: “Kamoa-Kakula is blessed with an incredible endowment of high-grade copper resources. Given that our underground mine development and ore production are both progressing well ahead of schedule, the plant expansion will allow the operations team to process significantly more high-grade copper ore directly from the Kakula Mine in the years ahead.

“Our orebody has a huge advantage in allowing us to adapt our mining cut-off to mine larger tonnages very efficiently, while maintaining grades above a desired level. The expansion also provides the team with the flexibility to utilize our surface stockpiles, for which the mining is already paid for, that totalled more than 4.4 million tonnes grading 4.61% copper at the end of January.”

Construction of Kamoa-Kakula’s Phase 2, 3.8-Mtpa concentrator plant almost is complete with early-stage commissioning activities now underway. Hot commissioning of the concentrator with first ore and initial copper concentrate production are both on track for April 2022.

Engineering and early works for the Phase 3 expansion, including a new box cut and twin declines to access new mining areas, is progressing quickly. A third, significantly larger concentrator is being designed and is expected to commissioned in Q4 2024. An updated pre-feasibility study, including the Phase 3 expansion, is expected in Q3 2022. Also underway are early works on a direct-to-blister flash smelter at Kamoa-Kakula that will incorporate leading-edge technology supplied by Metso Outotec of Finland, and have a nameplate capacity of 500,000 tonnes a year of approximately 99%-pure blister copper.

The Phase 1 concentrator currently is running at a throughput that is in excess of its 3.8-Mtpa design capacity by more than 22%, with 112% of design throughput achieved in January. Copper recoveries of above 87% also are consistently being achieved that are in excess of design recovery of 85.6%, depending on feed grade, with January’s recoveries approximately 2.7% higher.

Despite the Phase 1 concentrator incurring significant downtime for critical tie ins and changes required for the commissioning of the Phase 2 concentrator, the copper in concentrate produced in January totalled 18,824 tonnes ─ almost the same as December’s record production of 18,853 tonnes. January’s impressive operating performance of the Phase 1 concentrator is continuing in February. On February 7th, the concentrator set a new daily ore throughput record with 13,498 tonnes milled.

Figure 1: Kamoa-Kakula’s base-case, pro-forma copper production (after de-bottlenecking is complete) relative to the world’s projected top 10 producing mines in 2022 by paid copper production.

Source: Company filings, Wood Mackenzie (February 2022). Note: Kamoa-Kakula production of 435 kt paid copper production, or 450 kt copper in concentrate, is based on expected Phase 1 and 2 steady state production, following de-bottlenecking of both Phase 1 and 2 concentrators.

Steve Amos, Ivanhoe Mines’ Head of Projects, DRC, commented: “After successfully operating the Phase 1 concentrator for more than eight months, we’ve identified a number of relatively minor modifications to the concentrator that should increase ore throughput from the current design of 475 tonnes per hour to 580 tonnes per hour. These modifications include increasing the diameter of a number of pipes, replacing a number of motors and pumps with larger ones and installing additional flotation, concentrate-thickening, concentrate-filtration and tailings-disposal capacity.

“We expect the de-bottlenecking project to cost approximately US$50 million and take approximately 12 months to complete. These modifications will allow the team to consistently operate the concentrator plant at the increased throughput without compromising plant availability, copper recovery or copper concentrate grade. Engineering design is under way and procurement of long-lead items already has started. We expect to be in a position to increase Kamoa-Kakula’s combined processing capacity to 9.2 million tonnes of ore a year by Q2 2023.”

As announced earlier this year, the 2022 production guidance for the Kamoa-Kakula Copper Complex is between 290,000 to 340,000 tonnes of copper in concentrate. The figures are on a 100%-project basis and copper reported in concentrate is prior to refining losses or deductions associated with smelter terms.

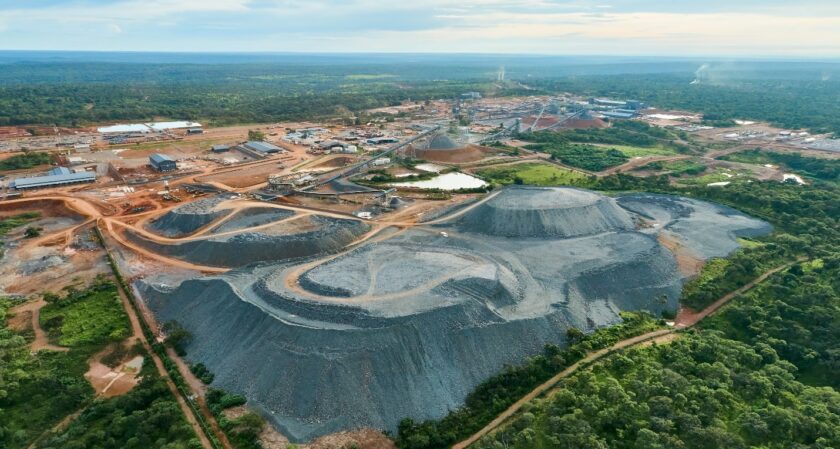

The Kamoa-Kakula Mining Complex, with the Phase 1 and Phase 2 concentrator plants circled in red.

Another view of the Kamoa-Kakula Mining Complex, with the Kakula North ore stockpiles in front and the Phase 1 and Phase 2 concentrators in the rear.

Commissioning team observing the delivery of first ore to Kamoa-Kakula’s Phase 2 high-pressure-grinding-rolls (HPGR) stockpile on February 18th.

Assembly of Kamoa-Kakula’s Phase 2 flotation cells now is complete and early-stage commissioning activities are underway.

Mill operator Rachel Museka, collecting pulp-density samples at Kamoa-Kakula’s Phase 1 concentrator.

Gracia Mbaka Indundu, Senior Operator, at the first two concentrate filter presses, which were supplied by Metso Outotec of Espoo, Finland.

Priscille Mandandj, Rachel Museka, Esther Kabiz and Flora Kaj Somp, celebrating the completion of construction of the Phase 2 ball mills.

Excavating crew at Kamoa-Kakula’s new box cut for the twin declines that will provide access to the Phase 3 mining areas. (L-R) Katshaba Gracien, Milto Bikos, Nkulu Mwepu, Maseo Kabey, Mandew Jean, and Mutomb Jasue.

Excavation work is advancing quickly at Kamoa-Kakula’s new box cut for the twin declines that will provide access to the Phase 3 mining areas.

134 total views , 1 views today