Kamoa-Kakula shatters previous production records, in March 2021

Kamoa-Kakula shatters previous production records, mining 400,000 tonnes of ore grading 5.36% copper in March, including 100,000 tonnes grading 8.70% copper from the centre of the Kakula Mine

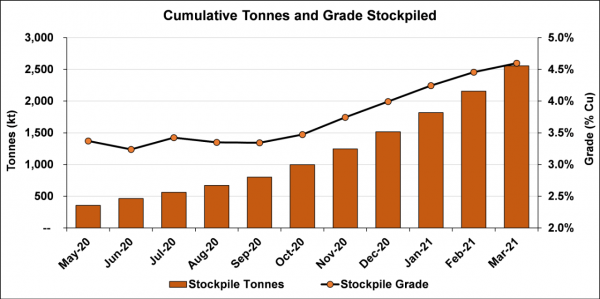

Pre-production ore stockpiles hold 2.56 million tonnes grading 4.60% copper, containing more than 117,000 tonnes of copper

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation 92% complete; commissioning of concentrator plant underway with first copper production on track for July 2021

Kamoa-Kakula’s main 220-kV substation energized with clean, renewable hydropower

Phase 2 expansion to 7.6 Mtpa progressing well toward a Q3 2022 start-up; engineering to commence for Phase 3 expansion to 11.4 Mtpa

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that underground ore production at the Kamoa-Kakula Copper Project in the Democratic Republic of Congo (DRC) mined and stockpiled a record 400,000 tonnes of ore grading 5.36% copper from the Kakula and Kansoko mines in March. This tonnage was 18% higher than the 339,000 tonnes mined and stockpiled in February.

The 400,000 tonnes mined in March comprised 364,100 tonnes grading 5.52% copper from the Kakula Mine, including 100,000 tonnes grading 8.70% copper from the mine’s high-grade centre, and 36,000 tonnes grading 3.78% copper from the Kansoko Mine.

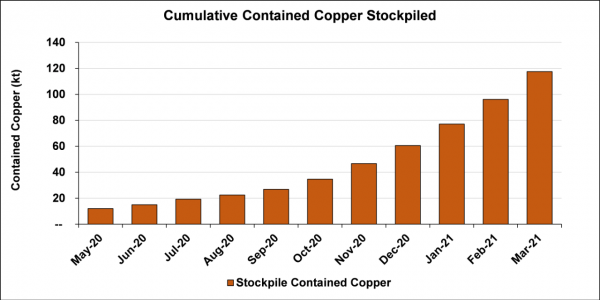

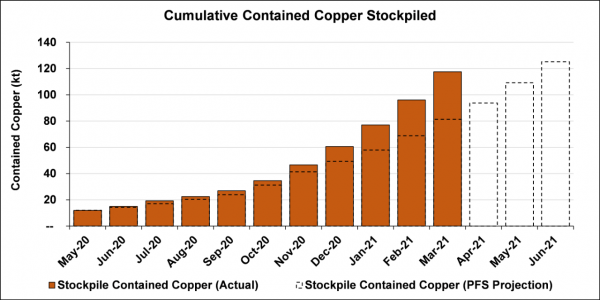

The project’s pre-production surface stockpiles now contain approximately 2.56 million tonnes of high-grade and medium-grade ore at an estimated blended average of 4.60% copper. Contained copper in the stockpiles increased by approximately 21,500 tonnes in March – to a cumulative total of more than 117,000 tonnes (the current copper price is approximately US$9,100 a tonne).

Kamoa-Kakula is on track to substantially exceed the 3.0 million tonnes of high-grade and medium-grade stockpiled ore, holding more than 125,000 tonnes of contained copper, that the 2020 pre-feasibility study projected would be stockpiled prior to the planned start of processing in July 2021.

Underground mine development continues well ahead of schedule

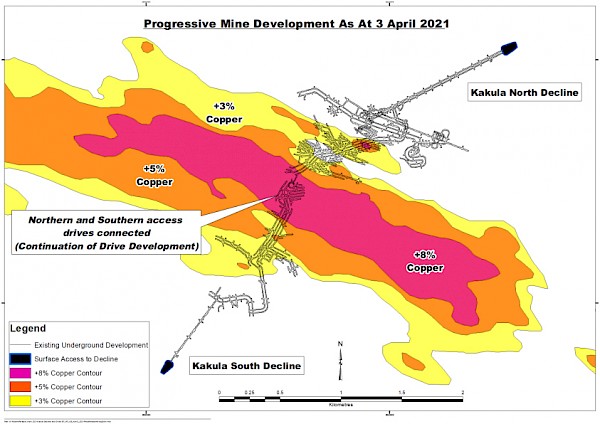

Kamoa-Kakula also set a fresh monthly mine development record in March, with an advancement of more than 3,100 metres, bringing total underground development to approximately 38.6 kilometres – around 13.5 kilometres ahead of schedule.

Drift-and-fill stoping operations are progressing well at the Kakula Mine, with approximately 70% of the ore production coming from stoping operations and the remainder coming from mine development activities. Drift-and-fill stoping is a highly-productive mining method of extracting underground ore, where a single tunnel, known as a stope, is extracted leaving an open void that is subsequently backfilled to allow for the extraction of the neighbouring stope in sequence.

Mark Farren, Kamoa Copper’s CEO, commented: “The outstanding mining rate in March was driven by improved crew efficiencies and a higher percentage of ore coming from drift-and-fill stoping operations. We are comfortable with the mining performance as we move into final commissioning of the Phase 1, 3.8-Mtpa concentrator plant. If we consistently mine at around 400,000 tonnes per month, we will continue to add to the surface stockpiles ahead of our Phase 2, 7.6 Mtpa concentrator plant commissioning, which is expected in Q3 2022.

“We will continue to monitor the mining rate to ensure there is a balance between the number of new mining crews we add to our underground operations and the surface ore stockpiles ahead of Phase 2 commissioning. The large surface ore stockpiles will give us considerable flexibility during the ramp up of Phase 2 production.”

Mr. Friedland added: “It is extremely encouraging to see how much better the project’s actual mining performance has been compared to the projections presented in the 2020 independent definitive feasibility and pre-feasibility studies. This is a testament to the determination and resilience of our on-site team that has worked tirelessly over the last year to deliver the first phase of this massive project on time and on budget, despite the challenges posed by COVID-19. As we continue to ramp-up underground operations at the Kakula and Kansoko mines, and expand the processing facilities, our primary focus remains on the health, safety and well-being of our employees and contractors.

The proceeds from our recently completed US$575 million, 2.50% convertible senior note financing opens the distinct possibility of earlier development of Kamoa-Kakula’s Phase 3 expansion to 11.4 Mtpa, which would bring copper production at the Tier One copper mine to approximately 530,000 tonnes, or approximately 1.2 billion pounds, per year. The funding also allows us to quickly expand our exploration program on our Western Foreland licences adjoining Kamoa-Kakula, in pursuit of our next world-scale copper discovery.”

Chancelle Kabinda, Utility Vehicle Operator – one of many talented Congolese women helping to build Kamoa-Kakula into the world’s next great copper mine.

Phase 1 copper production from the Kakula Mine is scheduled to begin in July 2021. Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated early average feed grade of more than 6.0% copper, ramping up to 7.6 Mtpa in Q3 2022.

Phases 1 and 2 combined are forecast to produce up to approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

Given the current copper price environment, Ivanhoe and its partner Zijin are exploring the acceleration of the Kamoa-Kakula Phase 3 concentrator expansion from 7.6 Mtpa to 11.4 Mtpa, which may be fed from expanded mining operations at Kansoko, or new mining areas at Kamoa North (including the Bonanza Zone) and Kakula West.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%).

A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

March’s ore production was 18% higher than February at slightly lower grades; pre-production surface ore stockpiles now total approximately 2.56 million tonnes grading 4.60% copper

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to March 2021.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines – May 2020 to March 2021.

Chart 3: Projected growth in contained copper in pre-production stockpiles at the Kakula and Kansoko mines up to July 2021. Dotted lines denote projections based on the 2020 pre-feasibility study.

The ore being mined from the northern portion of the Kakula Mine is transported to surface via the conveyor system and placed on a blended surface stockpile that now contains approximately 1.44 million tonnes grading an estimated 4.86% copper.

Additional pre-production ore stockpiles are located at the Kakula southern decline (826,000 tonnes at a blended grade of 4.56% copper) and the Kansoko decline (287,000 tonnes at blended grade of 3.37% copper).

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 1.44 million tonnes grading 4.86% copper.

Kakula southern decline blended ore stockpiles containing approximately 826,000 tonnes grading 4.56% copper (consisting of 380,000 high-grade tonnes @ 6.33% copper and 447,000 medium grade tonnes @ 3.06% copper).

Kansoko decline blended ore stockpiles containing 287,000 tonnes grading 3.37% copper (consisting of 50,000 high-grade tonnes @ 5.50% copper and 238,000 medium-grade tonnes @ 2.92% copper).

Figure 1: Underground development completed at Kakula Mine to April 3, 2021 (in black).

Construction of the initial 3.8-Mtpa concentrator plant and other surface infrastructure now 90% complete

Kamoa-Kakula’s initial 3.8-Mtpa concentrator plant is nearing completion and commissioning is well underway. The foundations for the Phase 2 concentrator plant are alongside the Phase 1 plant.

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation (covering mine infrastructure, concentrator plant and surface infrastructure) now is approximately 90% complete (as of end of March), compared to 86% at the end of February.

Watch a short video highlighting Kamoa-Kakula’s outstanding ESG initiatives: https://vimeo.com/533509420

Overall construction of the project’s first phase, 3.8-Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 92% complete (as of end of March), up from 85% complete at the end of February. The concentrator plant remains on track to be mechanically complete in Q2 2021, with first copper concentrate production scheduled for July 2021.

Delivery of equipment for the first concentrator plant effectively is complete with 2,426 truckloads of equipment and material having been delivered to site. The last shipments of transformers for emergency power and some components for the sand filter plant are scheduled to arrive this month; neither will delay commissioning.

Structural steel erection, platework installation and piping and valve installation for the first concentrator plant is effectively complete, with only minor small bore piping still outstanding.

Electrical, controls and instrumentation installation is the last activity before construction completion and subsequent commissioning. Cable installation and cable termination is nearing completion with the focus now on instrument cabling and terminations. Two plant electrical substations have been energized on temporary power (milling and flotation) to allow for early C2 (second-stage) commissioning, which involves energizing motor control centers and checking drives and electrical signals. Energizing of the main concentrator plant substation on permanent medium-voltage power is scheduled for early this month.

Punch listing and C1 (first-stage) commissioning sign off is well underway with approximately half of the 1,070 C1 certificates signed off and handed over from construction to commissioning. C2 commissioning has started in the milling and flotation areas using temporary power from the two substations.

Hong Wang, Mechanical Fitter, checking the alignment of pinion and girth gears of the primary ball mill during commissioning of the Phase 1 concentrator plant.

Electrical installation at the backfill plant is ongoing and construction completion is expected at roughly the same time as the concentrator plant. The backfill plant is scheduled to be complete well before paste backfill is required for mining operations.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage. Construction of the tailings storage facility is progressing well and is scheduled to be completed on time to receive tailings from the processing plant.

Kakula’s Phase 1, 3.8-Mtpa flotation cells, tailings and concentrate thickeners, and concentrate storage building at night. Foundations for the Phase 2 flotation cells are on the left.

Kakula’s Phase 1 ball mills at night.

Earthworks and civil works progressing well for the second 3.8-Mtpa concentrator plant, with the first delivery of long-lead items now on site

Construction of the second 3.8-Mtpa concentrator plant (Phase 2) is progressing well with the current focus on earthworks and civil works. Both earthworks and civil works are tracking slightly ahead of schedule. With orders for all the long-lead items of equipment for the Phase 2 concentrator placed in September 2020, procurement activities have focused on the remainder of the plant equipment. Structural steel fabrication is underway with the first batch complete and due to arrive on site in June. Contract negotiations for thesteel, mechanical, piping and plate erection are expected to conclude shortly.

Foundations for the second 3.8-Mtpa concentrator plant advancing quickly.

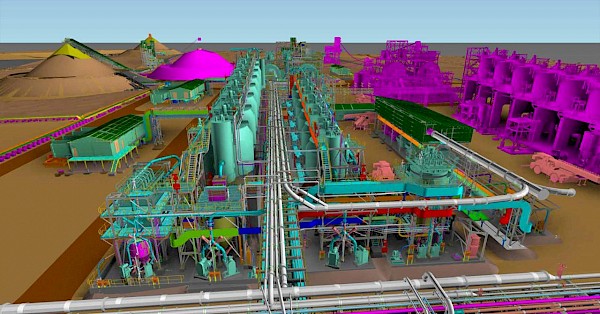

A 3D illustration of Kakula’s initial 3.8-Mtpa concentrator plant, with the Phase 2, 3.8-Mtpa processing plant shown in magenta. The picture immediately below shows the currentconstruction progress.

A 3D illustration of the finished ball mills area for the Phase 1, 3.8 Mtpa concentrator, with the next two ball mills for the Phase 2 concentrator plant shown in magenta. The picture immediately below shows the current construction progress.

A 3D illustration of Kakula’s first phase, finished backfill plant, with the current construction and the initial 3.8-Mtpa concentrator plant in the background shown immediately below.

Contractors installing metal sheeting on the concentrate storage building.

By-pass stockpile feed conveyor system, with the run-of-mine stockpile in the upper right corner.

Kakula’s mine water settling ponds that receive surplus water pumped from underground. Some of the water will be used in the concentrator plant.

Negotiations for the marketing of Kakula’s copper concentrates expected to conclude in April

Kamoa-Kakula is nearing completion of agreements with respect to the sale of its copper concentrates during Phase 1 operations. Kakula is expected to produce an extremely high-grade, clean copper concentrate (containing over 55% copper) that will be highly coveted by smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Kamoa-Kakula’s main 220-kV substation energized with clean, renewable hydropower; upgrading work at the Mwadingusha hydropower plant nearing completion

In December 2020, the 35-kilometre-long double circuit 220-kilovolt (kV) power line to Kamoa-Kakula was connected to the national electrical grid through theNew Western Dispatch substation in Kolwezi. Kamoa-Kakula’s main 220-kV substation was energized with 220-kV power from the national power grid on March 25 and the first of two 33-kV transformers on March 29th. The next milestone is to energize the main plant 33-kV substation, which will then allow power reticulation to all of the plant’s lower-voltage substations.

Two of the six new turbines at the Mwadingusha hydropower plant now have been synchronized to the national electrical grid, with each generating unit producing approximately 13 megawatts of power. The completion and commissioning of the hydropower plant’s remaining four generating units, in sequence, is in progress. This will ensure that Kamoa-Kakula’s power requirements are secured ahead of the commissioning of the concentrator plant.

The fully-refurbished Mwadingusha hydropower plant is expected to deliver approximately 78 megawatts of power to the national electrical grid.

Electrical engineers from Andritz Hydro of Switzerland, CEGELEC of France, and the DRC’s Société Nationale d’Electricité (SNEL), monitoring the commissioning of Mwadingusha’s turbines 2 and 3 from the control room. Commissioning of turbine 6, the fourth in the sequence of commissioning, is scheduled to start in mid-April.

Yves Tshivuadi, Cherry Picker Operator, and Idriss Bibwe, Mechanic Fitter, connecting a surge arrestor and voltage transformer at Kamoa-Kakula’s main 220-kV substation.

Ben Munanga, newly appointed Chairman of Kamoa Copper, monitoring the energizing of the main 220-kV substation along with members of senior management of SNEL and Kamoa Copper.

Members of SNEL’s senior management and senior members of Kamoa Copper at the energized Kakula 220-Kv substation. From left to right: Kayembe Bukasa Cedric, Divisional Head, Communications, SNEL; Johan Nortje, Engineering Manager, Kamoa Copper; Doudou Bakutu, Divisional Head of Protection & Metering, SNEL; Chris Kabongo, Senior Engineer, Kamoa Copper; and Gilbert Tshilumba, Divisional Head of High Voltage Customers, SNEL.

COVID-19 prevention and treatment initiatives enhanced while maintaining risk management strategy

Kamoa-Kakula continues to focus on prevention, preparation and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensures that positive cases are quickly identified, isolated and treated, with cross contamination kept to a minimum.

The project has a well-established COVID-19 isolation facility at the Kamoa Camp. Suspected cases and positive patients are moved to this facility, where they are isolated and treated. Once patients have recovered and are deemed no longer infectious, they can return to work only after an additional quarantine period determined by the project’s medical staff.

Kamoa-Kakula has successfully treated a number of symptomatic patients in the Kamoa Hospital, where highly-experienced doctors and nurses apply the latest medical treatments in a world-class facility.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of the workforce and community members.

Fabrice Mitonga, Process instructor (right), with a class of new recruits that will be operating the Phase 1 concentrator plant.

Jerome Mangenda, Miner trainee, practices explosives wiring procedures at the Kamoa-Kakula training centre.

Jean Kamwang, Headmaster and teacher, with some of his students at the newly renovated Agronomist Technical Institute in the local village of Musokantanda, a Kamoa-Kakula Livelihoods education initiative.

Marie Kapepa, a student at the Musokantanda Agronomist Technical Institute.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the DRC and at the Platreef palladium-platinum-nickel-copper-rhodium-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the DRC.

Kamoa-Kakula is expected to begin producing copper in July 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi will be powered by clean, renewable hydro-generated electricity and will be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe also is exploring for new copper discoveries on its wholly-owned Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project.

![]()