Ivanhoe Mines Achieves Early Production of Kamoa-Kakula Phase 3 Concentrate

Ivanhoe Mines’ Executive Co-Chair Robert Friedland announced on 11th June, ahead of his appearance at the 2024 Evercore Global Clean Energy & Transition Technologies Summit at the Mandarin Oriental Hotel in New York, that on June 10, 2024, first concentrate production by Kamoa-Kakula’s Phase 3 concentrator in the Democratic Republic of the Congo (DRC) was celebrated by the mine-site management and employees.

First copper concentrate was achieved approximately two weeks after the first feed of ore into the concentrator, as announced on May 28, 2024.

The Phase 3 concentrator expansion was completed nearly two quarters ahead of schedule and is expected to boost production to over 600,000 tonnes of copper per annum, with ramp-up to commercial production targeted for early in the third quarter.

The Phase 3 concentrator will process ore from the newly developed and adjacent Kamoa 1 and 2 underground mines, as well as connect the new Kansoko underground mine.

At 5 million tonnes per annum (Mtpa), the design capacity of the Phase 3 concentrator is 30% larger than the original design capacities of the Phase 1 and 2 concentrators, located approximately 10 kilometres to the south.

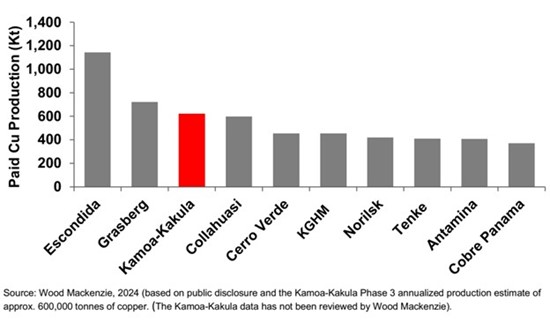

The Phase 3 concentrator increases the total design processing capacity of the Kamoa-Kakula Copper Complex to 14.2 Mtpa. Phase 3 is expected to increase annualized copper production to greater than 600,000 tonnes per annum, positioning Kamoa-Kakula as the world’s third-largest copper mining complex, and the largest copper mine on the African continent. See Figure 1.

Production from Kamoa-Kakula’s Phase 1 and 2 concentrators achieved a near record of 35,474 tonnes of copper in May. Production in May 2024, which was the best monthly performance of the past 12 months, benefitted from improved power stability since the end of the first quarter. Improved power stability has enabled increased mining rates of the higher-grade areas in the Kakula underground mine.

Improvements in power stability in recent months are due in large part to imported power from Zambia and Mozambique. An additional 20 megawatts (MW) of imported power have been secured since the beginning of June, increasing the total imported power consumed by the Kamoa-Kakula Copper Complex to 55 MW.

Subject to availability, it is expected that total imported power will increase up to 100 MW by the end of 2024. Kamoa-Kakula is expected to continue being supported by imported power until grid stability improves. A large majority of the imported power from Mozambique and Zambia is hydroelectric.

Concurrently, Kamoa Copper continues to work closely with the DRC’s state-owned power company, La Société Nationale d’Electricité (SNEL), to deliver the solutions for the identified causes of the instability experienced across the southern DRC’s grid infrastructure. Project delivery of the grid improvements is expected to be completed in 2025.

In addition, Kamoa Copper’s engineering team continues to expand its on-site, backup-power generator capacity, to ensure there is on-site redundancy for the Phase 1, 2 and 3 operations.

On-site, backup-power generator capacity is scheduled to increase, via a phased roll-out, to a total of more than 200 MW by the end of 2024.

The generator farm sites are being built adjacent to the Phase 1 and 2 concentrators and smelter at Kakula, as well as adjacent to the Phase 3 concentrator at Kamoa.

10 MW of new on-site, backup-power generator capacity was recently installed, increasing Kamoa-Kakula’s immediate total installed backup capacity to 73 MW.

An additional 60 MW is expected to be installed within the coming month, increasing the total backup capacity to 133 MW by the end of July.

Peak on-site power demand from Phase 1 and 2 operations is approximately 105 MW. The Phase 3 concentrator adds an additional power requirement of 45 MW, once fully ramped in the third quarter. In addition, the smelter will require a further 75 MW of power once fully ramped up.

(L-R) Eddie Mong, Senior Engineer; Riaan Vermeulen, Managing Director; Dodo Mbay, Executive, Concentrators; Minty Cai, Chief Executive, Finance; Zhang “Frank” Xingxun, Executive Director; Annebel Oosthuizen, Chief Executive, Commercial; and, Ion Muzama Sumbu, Managerial Lead, Concentrators of Kamoa Copper holding the batch of first concentrate from the Phase 3 concentrator on June 9, 2024.

Significant growth opportunities progressing to further increase copper production with ‘Project 95’, Phase 3 de-bottlenecking program, and accelerating Phase 4 expansion and beyond.

Basic engineering of the previously announced “Project 95” is expected to be completed shortly. Project 95 is an initiative targeting an increased overall metallurgical copper recovery rate of Kamoa-Kakula’s Phase 1 and 2 concentrators of approximately 95%, up from the current rate of approximately 87%.

Once the Phase 3 concentrator has achieved commercial production, Kamoa-Kakula’s engineering team will gather operating data with the view to initiating a de-bottlenecking program to further increase the Phase 3 concentrator processing capacity above 5 Mtpa.

The Phase 1 and 2 concentrators completed a de-bottlenecking program in February 2023, which increased processing capacity by approximately 20% above the original design throughput.

Following the completion of Phase 3, and given current market conditions, Kamoa-Kakula’s engineering team is investigating the acceleration of the project’s planned Phase 4 expansion.

The Phase 4 concentrator will be positioned adjacent to the Phase 3 concentrator, with a minimum processing capacity of 5 Mtpa, and will share common infrastructure with Phase 3, including the front end (crushing and screening plant), which will reduce capital costs.

An updated life-of-mine integrated development plan for the Kamoa-Kakula Copper Complex, including the Phase 3 expansion, smelter and Project 95, as well as further optimization initiatives and the planned Phase 4 expansion is expected to be completed by the end of 2024.

Exploration work is also progressing well on the planned 70,000-metre drill program at Ivanhoe’s majority-owned, 2,650-km2 Western Foreland license package adjacent to Kamoa-Kakula. Currently, there are approximately 10 drill rigs active in the Makoko and Kitoko areas.

This initial phase of the program is designed to expand and delineate these high-grade copper discoveries ahead of potential engineering and planning work to study opportunities to also accelerate copper production growth from these licenses.

Further exploration is planned on regional targets deemed prospective for additional sediment-hosted, high-grade copper deposits.

Senior management addressing workers inside the Phase 3 concentrate storage and load-out facility, during the celebration of first concentrate on June 9, 2024.

Sunrise June 9, 2024, over the Phase 3 concentrator’s ball mills. Construction of the Phase 3 concentrator was completed on budget and several months ahead of schedule.

Disclosure of technical information

Disclosures of a scientific or technical nature at the Kamoa-Kakula Copper Complex in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr.

Amos is not considered independent under NI 43-101 as he is Ivanhoe Mines’ Executive Vice President, Projects. Mr. Amos has verified the technical data disclosed in this news release.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Copper Complex, which is available on the company’s website and under the company’s SEDAR+ profile.

-Kamoa-Kakula Integrated Development Plan 2023 Technical Report dated March 6, 2023, prepared by OreWin Pty Ltd.; China Nerin Engineering Co. Ltd.; DRA Global; Epoch Resources; Golder Associates Africa; Metso Outotec Oyj; Paterson and Cooke; SRK Consulting Ltd.; and The MSA Group.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Copper Complex cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

![]()