Hitachi Debuts Engineless Full Battery Dump Truck for FQMs’ Kansanshi Mine in Zambia

Hitachi Construction Machinery Co., Ltd. completed the test machine version of an engineless, full battery rigid frame dump truck (“full battery dump truck”), and on January 20, 2024, test machine will be shipped from Hitachi Construction Machinery’s Hitachinaka-Rinko Works (Hitachinaka, Ibaraki Prefecture, Japan) to the Kansanshi copper and gold mine operated by First Quantum Minerals Ltd, in the Republic of Zambia.

With environmental awareness on the rise in the mining industry, there is growing interest in the electrification of mining machinery as part of efforts to reduce greenhouse gas emissions.

To meet the high customer demand for the electrification of dump trucks in particular, which are operated in large numbers at mining sites, Hitachi Construction Machinery began collaborating with ABB Ltd.

(“ABB”) in June 2021 to develop the full battery dump truck. On March 1, 2023, Hitachi Construction Machinery signed a letter of intent (LOI) with First Quantum to establish a zero-emission partnership, and the companies plan to conduct technological feasibility trials using the full battery dump truck test machine at First Quantum’s Kansanshi copper and gold mine.

Hitachi Construction Machinery has accelerated the development speed of the full battery dump truck by applying proven technology from the current trolley charging type rigid dump trucks.*

Hitachi Construction Machinery tested the basic operations of the full battery dump truck test machine at Hitachinaka-Rinko Works, by gradually combining the battery charging and discharging system, pantograph, and other power supply systems with the drive system that controls the travel of the dump truck.

After it was confirmed that all systems operate properly, the test machine will be sent to the mining site in Zambia. The technological feasibility trials, which are set to begin in mid-2024, aim to verify the basic performance of operations required of a dump truck, such as traveling, turning, and stopping under actual operating loads, as well as the battery charging and discharging cycles.

First Quantum, which presently operates 41 Hitachi Construction Machinery (diesel) trolley trucks (39 EH3500AC-II and two EH3500AC-3 rigid dump trucks) at the Kansanshi copper and gold mine, already has much of the infrastructure required for full battery dump trucks in place.

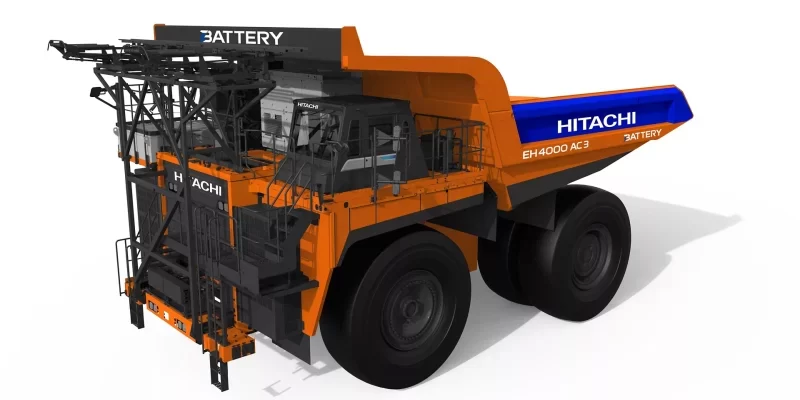

Conceptual image of completed full battery rigid dump truck

Going forward, the Hitachi Construction Machinery Group will continue collaborating with customers while leveraging their expertise in the development of (diesel) trolley trucks, as well as their extensive delivery record, to accelerate the development speed of the full battery dump truck, thereby contributing to the achievement of virtually zero greenhouse gas emissions from mining machinery.

* Machines are not equipped with batteries, and instead use a system that draws electric power from the trolley power supply to drive the AC motor when traveling uphill.

In areas with no trolley power line or on downhill slopes, charging is not performed and the machines run on electric power supplied from the generator driven by the diesel engine.

![]()