Ivanhoe Mines issues Q1 financial results and review of mine construction progress and exploration activities

Copper production at the Kamoa-Kakula Mine to begin imminently; first phase projected to produce approximately 200,000 tonnes of copper per year

Kamoa-Kakula’s Phase 2 expansion, scheduled for Q3 2022, will double annual copper output to approximately 400,000 tonnes

Ivanhoe Mines pledges net-zero greenhouse gas emissions at the Kamoa-Kakula Copper Mine

Expanded 2021 exploration program underway on Ivanhoe’s Western Foreland licences, searching for DRC’s next tier-one copper discovery

Development of the world-scale Platreef palladium, platinum, rhodium, nickel, copper and gold project in South Africa making good progress

TORONTO, CANADA ‒ Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) today announced its financial results for the three months ended March 31, 2021. Ivanhoe Mines is a Canadian mining company advancing its three mining projects in Southern Africa: the Kamoa-Kakula copper mining complex in theDemocratic Republic of Congo (DRC); the Platreef palladium-platinum-rhodium-nickel-copper-gold discovery in South Africa; and the extensive upgrading of the historic Kipushi zinc-copper-lead-germanium mine, also in the DRC. Ivanhoe also is exploring for new copper discoveries on its Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project. All figures are in U.S. dollars unless otherwise stated.

HIGHLIGHTS

- Development of the Kakula Mine, the first of multiple, planned mining areas at Ivanhoe Mines’ Kamoa-Kakula joint-venture copper project, has advanced ahead of schedule and first copper concentrate production is expected within a few weeks. Lower-grade ore will be fed into the plant during the final commissioning phase, to ensure plant performance and copper recovery are satisfactory before increasing the head grade.

- Kamoa-Kakula’s Phase 2 construction is progressing slightly ahead of plan and is scheduled to start up in Q3 2022, which will see a doubling of mill throughput to 7.6 million tonnes per annum (Mtpa). Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

- Kamoa-Kakula’s initial production guidance, on a 100%-project basis, is between 80,000 and 95,000 tonnes of copper in concentrate for the remainder of 2021.

- At the end of April 2021, Kamoa-Kakula’s pre-production ore stockpiles held three million tonnes grading 4.74% copper, containing more than 140,000 tonnes of copper.

- Given the current copper price environment, Ivanhoe, together with its partner Zijin, is exploring the acceleration of the Kamoa-Kakula Phase 3 concentrator expansion from 7.6 Mtpa to 11.4 Mtpa, which may be fed from expanded mining operations at Kansoko or a new mining area at Kamoa North (including the Bonanza Zone). Kamoa Copper also is refining its longer-term downstream processing strategy, including the potential construction of a smelter or hydrometallurgical processing facility.

- In March 2021, Ivanhoe Mines completed a US$575 million, 2.50% convertible senior notes offering. The funding positions Ivanhoe and joint-venture partners to fast-track additional hydropower upgrades to provide sufficient clean and renewable electricity for Kamoa-Kakula expansions to 19 million tonnes of ore per annum and beyond, including a smelter. Funding also allows for expansion and acceleration of the Western Foreland exploration program, in pursuit of the next world-scale copper discovery.

- In April 2021, Ivanhoe announced that Ivanhoe Mines Energy DRC signed an agreement with the DRC’s state-owned power company SNEL to upgrade a major turbine at the Inga II hydropower facility. The upgraded turbine is expected to produce 162 megawatts of clean, renewable hydropower, providing the Kamoa-Kakula Copper Mine with sufficient, sustainable electricity for future expansions, including a copper smelter.

- In May 2021, Ivanhoe pledged to achieve net-zero operational greenhouse gas emissions (Scope 1 and 2) at the industry-leading Kamoa-Kakula Copper Mine. Since the mine already is powered by clean, renewable hydro-generated electricity, the focus of the company’s net-zero commitment will be on electrifying the project’s mining fleet with new, state-of-the-art equipment powered by electric batteries or hydrogen fuel cells, when commercially available.

- In February, Ivanhoe began its 2021 exploration program on its Western Foreland licences that cover a combined area of approximately 2,550 square kilometres in close proximity to Kamoa-Kakula. The 2021 exploration budget has been increased to $21 million to include additional drilling and surveys. The budget may be further expanded based on program results.

- To support Ivanhoe’s growth plans, future capital needs and widen shareholder support, the company is considering the viability of seeking one or more listings on international stock exchanges. Any such listing(s) would be subject to market conditions and meeting listing requirements.

- In February 2021, Ivanhoe announced that its South African subsidiary, Ivanplats, is arranging project-level financing of up to $420 million to advance development of the world-scale Platreef palladium, platinum, rhodium, nickel, copper and gold project in South Africa.

- Ivanplats has signed a non-binding term sheet with Orion Mine Finance, a leading international provider of production-linked stream financing to base and precious metals mining companies, for a $300-million gold, palladium and platinum streaming facility. Ivanplats also has appointed two prominent, international commercial banks – Societe Generale and Nedbank – as mandated lead arrangers for a senior project debt facility of up to $120 million.

- Ivanplats’ proposed financings follow the November 30, 2020 issuance of the outstanding findings of an independent Platreef Integrated Development Plan 2020 (Platreef IDP20), which consists of an updated feasibility study (Platreef 2020 FS) and a preliminary economic assessment (Platreef 2020 PEA). The initial capital cost for the phased development plan under the Platreef 2020 PEA, starting at a mining rate of 700,000 tonnes per annum (700 ktpa), is estimated at $390 million.

- Detailed engineering is underway on Platreef’s 700-ktpa initial mine design, 770-ktpa concentrator and associated infrastructure for the phased development plan, which is scheduled to be incorporated into an updated feasibility study before the end of 2021. The Shaft 1 changeover is progressing well in preparation for permanent hoisting by early 2022.

- At the Kipushi Mine redevelopment project in the DRC, the Kipushi Project’s draft feasibility study, and development and financing plan are being reviewed by Ivanhoe Mines together with its joint-venture

- Ivanhoe has made excellent progress in upgrading Kipushi’s underground infrastructure to allow for mining to quickly begin at the ultra-high-grade Big Zinc orebody. Resumption of production at the mine now requires the construction of a surface processing plant and other related surface production facilities. Discussions are continuing with Gécamines to advance a new era of production at Kipushi andit is anticipated that these discussions will be concluded with the finalization of the feasibility study and the agreement on the development and financing plan by mid-2021.

- At the end of Q1 2021, Kamoa-Kakula had reached 628,000 work hours free of a lost-time injury, Kipushi had reached 3.14 million work hours free of a lost-time injury, and Platreef had reached 202,000 work hours free of a lost-time injury.

Principal projects and review of activities

1. Kamoa-Kakula Project

39.6%-owned by Ivanhoe Mines

Democratic Republic of Congo

The Kamoa-Kakula Project, a joint venture between Ivanhoe Mines and Zijin Mining, has been independently ranked as the world’s fourth-largest copper deposit by international mining consultant Wood Mackenzie. The project is approximately 25 kilometres west of the town of Kolwezi and about 270 kilometres west of Lubumbashi.

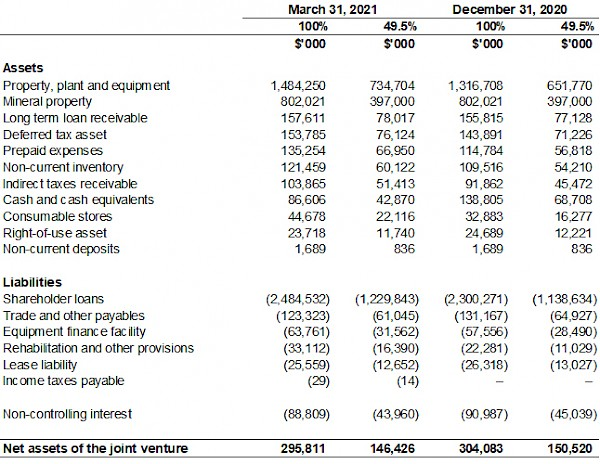

Ivanhoe sold a 49.5% share interest in Kamoa Holding Limited (Kamoa Holding) to Zijin Mining in December 2015 for an aggregate consideration of $412 million. In addition, Ivanhoe sold a 1% share interest in Kamoa Holding to privately-owned Crystal River for $8.32 million – which Crystal River will pay through a non-interest-bearing, 10-year promissory note. Since the conclusion of the Zijin transaction in December 2015, each shareholder has been required to fund expenditures at the Kamoa-Kakula Project in an amount equivalent to its proportionate shareholding interest in Kamoa Holding.

A 5%, non-dilutable interest in the Kamoa-Kakula Project was transferred to the DRC government on September 11, 2012, for no consideration, pursuant to the 2002 DRC mining code. Following the signing of an agreement with the DRC government in November 2016, in which an additional 15% interest in the Kamoa-Kakula Project was transferred to the DRC government, Ivanhoe and Zijin Mining now each hold an indirect 39.6% interest in the Kamoa-Kakula Project, Crystal River holds an indirect 0.8% interest and the DRC government holds a direct 20% interest. Kamoa Holding holds an 80% interest in the project.

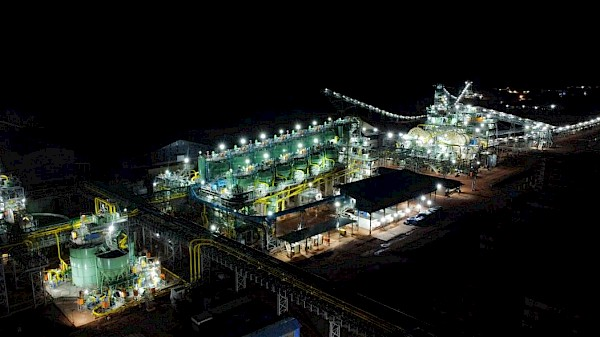

The Kakula concentrator plant and some of approximately 7,000 employees and contractors who helped construct the mine ahead of schedule and within budget.

Phase 1 concentrator plant now energized with permanent hydroelectricity.

Health and safety at Kamoa-Kakula

At the end of March 2021, the Kamoa-Kakula Project reached 627,876 work hours free of a lost-time injury. Nine lost-time injuries occurred in Q1 2021. The project continues to strive toward its workplace objective of zero harm to all employees and contractors.

Kamoa-Kakula has successfully focused on prevention, preparation and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensured that positive cases were quickly identified, isolated and treated, with cross contamination kept to a minimum. Maintaining this high standard of risk management remains a daily focus, to prevent future cases.

The Kamoa COVID-19 hospital continues to treat patients when required, as construction progresses for the expansion and upgrade of the primary healthcare wing of the hospital. Kamoa-Kakula’s highly experienced doctors and nurses apply the latest medical treatments, supported by a world-leading emergency response and paramedic team.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of the workforce and community members.

The new primary healthcare wing of the Kamoa hospital under construction.

Initial 3.8-Mtpa Kakula concentrator plant nearing completion, with first copper concentrate production within weeks

Overall progress of Kamoa-Kakula’s first phase, 3.8-Mtpa mining and milling operation (covering mine infrastructure, concentrator plant and surface infrastructure) now is approximately 94% complete (as of end of April), compared to 90% at the end of March.

Overall construction of the project’s first phase, 3.8-Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 98% complete (as of end of April), up from 92% complete at the end of March. The concentrator plant is essentially mechanically complete, with first copper concentrate production scheduled for later this month or early June. Lower-grade ore will be fed into the plant during the final commissioning phase, to ensure plant performance and copper recovery are satisfactory before increasing the head grade.

Structural steel erection, platework installation and piping and valve installation for the first concentrator plant are effectively complete, as is electrical, controls and instrumentation installation.

The main mine 220-kilovolt (kV) Kamoa Consumer Substation (KCS) has been energized on grid power, as has the 33kV KCS substation. In addition, the main plant 33kV substation and all the plant medium-voltage and low-voltage substations have been energized, and the concentrator plant is fully energized.

Construction complete (C1) sign off is nearing completion with approximately 75% of the certificates signed off and handed over from construction to commissioning. C2 (pre commissioning) commissioning is well underway with some areas (crushing and screening, milling) more than 90% complete. Early C3 activities (checking for leaks, certain instrument calibration, control-loop checks) have started with water being circulated through certain areas in the plant.

Electrical installation at the backfill plant is ongoing and the backfill plant is scheduled to be completed in July 2021, well before paste backfill is required for mining operations.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one-half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage. Construction of the tailings storage facility is progressing well and is scheduled to be completed on time to receive tailings from the processing plant.

Construction and commissioning of the surface bulk reclaim tip, bypass conveyor system and run-of-mine stockpile feed conveyor now is complete. The bulk reclaim tip system will be used to feed ore from Kakula’s surface stockpiles to the processing circuit, as well as ore from the Kansoko Mine when second phase operations begin.

The Phase 1 concentrator plant, now mechanically complete.

Copper production guidance for 2021

The Kamoa-Kakula concentrator plant is essentially mechanically complete and first copper concentrate production is scheduled for later this month or early June 2021. Assuming first production starts at that time, Ivanhoe’s guidance for contained copper in concentrate expected to be produced by the Kamoa-Kakula Project for the balance of 2021 assumes a ramp-up from first production in line with published technical disclosures, and is as follows:

Kamoa-Kakula Project 2021 Guidance

Contained Copper in Concentrate 80,000 to 95,000 tonnes

All figures in the above table are on a 100%-project basis. Metal reported in concentrate is prior to refining losses or deductions associated with smelter terms. Cost guidance is expected to be provided once the Kamoa-Kakula Project’s Phase 1 plant has reached steady state production. Guidance involves estimates of known and unknown risks, uncertainties and other factors which may cause the actual results to be materially different.

Kamoa-Kakula’s Phase 1 backfill plant with concentrator plant in the background.

Construction of Phase 2 of the Kamoa-Kakula project is well underway and Phase 3 expansion is being explored

Construction of the second 3.8-Mtpa concentrator plant is progressing well toward a Q3 2022 start-up, with the current focus on earthworks and civil works. Both earthworks and civil works are tracking slightly ahead of schedule. With orders for all the long-lead items of equipment for the Phase 2 concentrator placed in September 2020, procurement activities have focused on the remainder of the plant equipment. Structural steel fabrication is underway with the first batch complete and due to arrive on site in June 2021.

Given the current copper price environment, Ivanhoe and its partner Zijin are exploring the acceleration of the Kamoa-Kakula Phase 3 concentrator expansion from 7.6 Mtpa to 11.4 Mtpa, which may be fed from expanded mining operations at Kansoko, or new mining areas at Kamoa North (including the Bonanza Zone) and Kakula West.

Foundations for the Phase 2 ball mills and flotation cells advancing rapidly.

Underground development more than 13 kilometres ahead of plan at the end of Q1 2021

Kamoa-Kakula also set a monthly mine development record in March, with advancement of more than 3,100 metres, bringing total underground development to approximately 38.6 kilometres – approximately 13.5 kilometres ahead of schedule. A total of 8.8 kilometres of underground development was completed in Q1 2021. Good progress continued in early Q2 2021 and further increased the underground development to more than 42 kilometres at the end of April 2021, which is 15 kilometres ahead of schedule.

Drift-and-fill stoping operations are progressing well at the Kakula Mine, with approximately 70% of the ore production coming from stoping operations and the remainder coming from mine development activities. Drift-and-fill stoping is a highly-productive mining method of extracting underground ore, where a single tunnel, known as a stope, is extracted leaving an open void that is subsequently backfilled to allow for the extraction of the neighbouring stope in sequence. The backfill plant, which will mix tailings from the processing plant with cement to produce paste backfill, will begin pumping backfill to the underground operations in July 2021.

Large-scale, mechanized mining operations are progressing well at the Kakula and Kansoko mines.April represented the third consecutive month of mining in excess of the 3.8-Mtpa milling rate, reducing start-up risk as the stockpile is not expected to be drawn down significantly until the Phase 2 processing plant comes on stream in Q3 2022.

Pre-production ore stockpiles now hold approximately 3.0 million tonnes grading 4.74% copper, containing more than 140,000 tonnes of copper

At the end of December 2020, Kamoa-Kakula’s pre-production surface stockpiles contained approximately 1.52 million tonnes of high-grade and medium-grade ore at an estimated blended grade of 4.03% copper, containing more than 61,000 tonnes of copper. The project’s combined medium-grade and high-grade ore mined was approximately 300,000 tonnes at an average grade of 5.45% copper in January 2021, approximately 339,000 tonnes at an average grade of 5.50% copper in February 2021, and approximately 400,000 tonnes at an average grade of 5.36% copper in March 2021. This brings the project’s total pre-production high- and medium-grade ore surface stockpiles to approximately 2.56 million tonnes at an estimated grade of 4.60% copper as of the end of March 2021.

A further 409,000 tonnes were mined in April and comprised 357,000 tonnes grading 5.70% copper from the Kakula Mine, including 121,000 tonnes grading 8.40% copper from the mine’s high-grade centre, and 51,000 tonnes grading 5.85% copper from the Kansoko Mine.

The project’s pre-production surface stockpiles now contain more than 3.0 million tonnes of high-grade and medium-grade ore at an estimated blended average of 4.74% copper. Kamoa-Kakula now has reached the 3.0-million-tonne target of mined high-grade and medium-grade ore, several months ahead of the timeline estimated in the 2020 pre-feasibility study.

Kakula’s main pre-production stockpile and concentrator plant. This stockpile, one of three at Kamoa-Kakula, currently contains approximately 1.64 million tonnes grading 4.93% copper.

Kamoa-Kakula close to finalizing agreements for the sale of its copper concentrates during Phase 1 operations

Kakula is expected to produce an extremely high-grade, clean copper concentrate (containing over 55% copper) that will be highly coveted by smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Offtake agreements for copper concentrates produced during Phase 1 operations are nearing final, and include arrangements to utilize local smelter capacity to produce blister copper ingots, and also to export concentrates directly.

Upon receipt of final documentation and board approvals from Kamoa-Kakula’s joint-venture partners, as well as from Kamoa Copper SA, Ivanhoe plans to issue a news release providing details of the marketing arrangements.

Draw down of equipment financing facility successfully commenced

On December 1, 2020, Ivanhoe announced the Kamoa-Kakula Project had secured an equipment financing facility of up to EUR 176 million (approximately $211 million), together with a $9 million down-payment facility to be used to purchase underground mobile mining equipment and services from leading Swedish manufacturers Sandvik AB and Epiroc AB, and Finnish manufacturer Normet Oy.

The facility has an availability period of three years and amortizes over five years from utilization and is tied to underground mining equipment at the Kamoa-Kakula Project. The Swedish Export Credit Agency (EKN) has provided both political and commercial cover to the lenders and receives a one-off premium per tranche’s first utilization.

After the completion of all conditions precedent, the Kamoa-Kakula Project completed the draw-down of $9 million of the down-payment facility and an equivalent of $56 million of the equipment financing in December 2020. In Q1 2021, further draw-downs of the equipment financing equivalent of $7.2 million were completed. Further draw-downs under the equipment finance facilities remain subject to conditions precedent customary for facilities of this nature. The company expects the conditions precedent to be met prior to each utilization.

The equipment finance is secured only by the equipment that is being financed. The down-payment facility is unsecured. No guarantee is required from any of the sponsors or parent companies with Kamoa Holding Limited issuing a non-binding Letter of Support, confirming its support for the project.

In addition, Gold Mountains (H.K.) International Mining Company, a subsidiary of Zijin Mining Group, has provided Kamoa Holding Limited with a limited recourse line of credit of $200 million secured by the project’s pre-production ore stockpiles to fund the Phase 2 concentrator expansion. Kamoa Holding has not yet drawn on this line of credit.

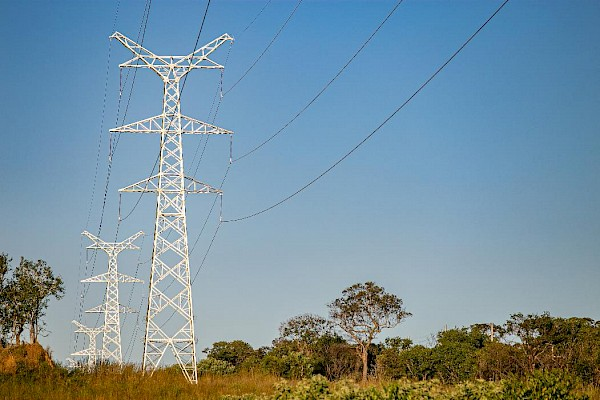

Kamoa-Kakula connected to the national power grid, providing clean, renewable 220-kV hydropower

The mine is receiving hydroelectric power for the Kamoa 120-kilovolt (kV) overhead line via the 18-megawatt mobile substation, which is connected to the national grid. Energizing of the permanent 35-kilometre, 220-kV power line connecting the new Western Dispatch substation in Kolwezi to Kamoa-Kakula, and thereby supplying the project with reliable and clean hydro-generated electricity from the national grid, was achieved in December 2020. This was a major milestone in securing permanent grid power for the project.

The main mine 220-kilovolt (kV) Kamoa Consumer Substation (KCS) has been energized on grid power, as has the 33kV KCS substation. The main plant 33kV substation and all the plant medium-voltage and low-voltage substations also have been energized, and the plant now is electrically live.

Towers along the new 35-kilometre, 220-kV power line connecting the new Western Dispatch substation in Kolwezi to Kamoa-Kakula, supplying the project with reliable and clean hydro-generated electricity from the national grid.

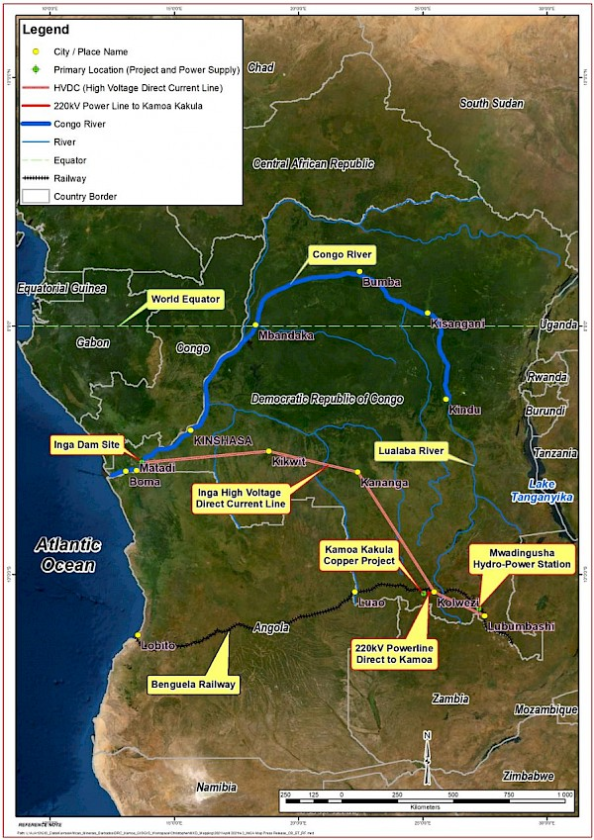

Agreement reached to upgrade major turbine at the Inga II hydropower facility

On April 26, 2021, Ivanhoe announced that Ivanhoe Mines Energy DRC signed an agreement with the DRC’s state-owned power company SNEL to upgrade a major turbine at the Inga II hydropower facility. The upgraded turbine is expected to produce 162 megawatts (MW) of clean, renewable hydropower, providing the Kamoa-Kakula Copper Mine with sufficient, sustainable electricity for future expansions, including its own copper smelter.

Aerial view of the Inga I (rear) and Inga II (front) hydropower plants on the Congo River. The penstock funneling water to turbine 5 at Inga II is circled in red.

The map below shows the Inga andMwadingusha hydropower complexes, theInga high-voltage power line, the Kamoa-Kakula Project, the new 220-kV power line connecting Kamoa-Kakula to the national grid at Kolwezi, and the Benguela railway connecting the DRC to the Angolan port of Lobito.

Ongoing upgrading work enables Mwadingusha hydropower station to supply clean, sustainable electricity

The upgrading work at the Mwadingusha hydropower plant is nearing completion with the synchronization of the first turbine achieved in December 2020. Three of the six new turbines at the Mwadingusha hydropower plant now have been synchronized to the national electrical grid, with each generating unit producing approximately 13 MW of power. Electricity from all of Mwadingusha’s six turbines, with an upgraded output of 78 MW, is expected to be integrated into the national power grid in Q2 2021.

The work is being conducted by engineering firm Stucky of Lausanne, Switzerland, under the direction of Ivanhoe Mines and Zijin Mining, in conjunction with the DRC’s state-owned power company, La Société Nationale d’Electricité (SNEL).

Aerial view of the 78-MW Mwadingusha hydropower plant, the reservoir and the community of Mwadingusha.

Engineering, procurement and construction of other surface infrastructure rapidly progressing

Beijing-based CITIC Construction Co., Ltd. is building Kakula’s first phase, backfill paste plant. The backfill plant will be used to mix tailings from the concentrator plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one-half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage. Construction of the backfill plant is progressing in parallel with the concentrator plant and is expected to be commissioned in July 2021.

Construction of the tailings storage facility is progressing well and is scheduled to be completed well ahead of the required date.

Construction of the surface bulk reclaim tip, bypass conveyor system and run-of-mine stockpile feed conveyor also is progressing well, with first commissioning and tie into the main decline conveyor planned for early 2021. The bulk reclaim tip system will be used to feed ore from Kakula’s surface stockpiles to the processing circuit, as well as ore from the Kansoko Mine when second phase operations begin.

Kamoa-Kakula aiming to become the first net-zero carbon emitter among the top-tier copper mines by electrifying its mining fleet with state-of-the-art equipment powered by electric batteries or hydrogen fuel cells

On May 5, 2021, Ivanhoe Mines announced its pledge to achieve net-zero operational greenhouse gas emissions (Scope 1 and 2) at the industry-leading Kamoa-Kakula Copper Mine in the Democratic Republic of Congo.

In support of the Paris Agreement on climate change, and in the spirit of the commitments at the recent virtual global climate conference by the Chinese and American governments to sharply cut emissions, Ivanhoe Mines has committed to working with its joint-venture partners and leading underground mining equipment manufacturers to ensure that Kamoa-Kakula becomes the first net-zero operational carbon emitter among the world’s top-tier copper producers.

Since the Kamoa-Kakula mine and concentrator plant already are powered by clean, renewable hydro-generated electricity, the focus of the company’s net-zero commitment will be on electrifying the project’s mining fleet with new, state-of-the-art equipment powered by electric batteries or hydrogen fuel cells.

Kamoa-Kakula is working closely with its mining equipment suppliers to decrease the use of fossil fuels in its mining fleet, and evaluate the viability, safety and performance of new electric, hydrogen and hybrid technologies. The mine plans to introduce them into its mining fleet as soon as they become commercially available.

Enriching communities through sustainable development

The Sustainable Livelihoods Program was founded in 2010 to strengthen food security and farming capacity in the host communities near Kamoa-Kakula by establishing an agricultural training garden and support for farmers at the community level. Today, approximately 467 community farmers are benefiting from the Sustainable Livelihoods Program, producing high-quality food for their families and selling the surplus for additional income.

The Sustainable Livelihoods Program, which commenced with maize and vegetable production, now includes fruit, aquaculture, poultry and honey. The construction of 100 new fish ponds currently is underway, to contribute toward local entrepreneurship and enhanced regional food security. The Musokantanda Agronomist Secondary School, constructed and equipped during 2020, now serves as a research facility and offers educational programs to 118 students, as well as training programs to local farmers. Plans also are underway for a collaboration between the agronomy school and the University of Kolwezi, which will provide further practical training for students.

Additional non-farming-related activities continued and included education programs, a community brick-making program, a sewing program, and the supply of fresh water to a number of local communities using solar-powered boreholes. To ensure that the sewing team is geared to commence operations and that their production of Kamoa-Kakula personal protective equipment (PPE) and other garments meets quality standards, 28 members of the project are undergoing professional training for six months.

The new Muvunda Primary School, catering to 206 students, has been opened and construction and equipping of the Kaponda Primary School is underway. Eight out of a planned 29 boreholes were drilled in communities using local contractors, providing 4,244 community members with easy access to clean water.

Construction of resettlement houses for the relocation program continued with 13 more households relocated to the Kaponda host site, bringing the total to 74 homes relocated and 10 households remaining. Land replacement was completed for 108 project-affected people in the Kamoa North area. The remaining families are scheduled for relocation upon completion of the construction of their new homes. The entire Kakula Mine area, including the tailings dam area, will be secured once these relocation phases are complete.

L-R: Local community members Dennis Kabadi, Ines Lumbwe, Simon Ilonga, and Hernestine Hlumbwe at the Kamoa-Kakula sewing centre. The sewing project, nicknamed Salamah (‘security and peace’ in Swahili), was initiated by Kamoa-Kakula’s Local Economic Development team in 2013 and has since seen significant growth and development.

2. Platreef Project

64%-owned by Ivanhoe Mines

South Africa

The Platreef Project is owned by Ivanplats (Pty) Ltd (Ivanplats), which is 64%-owned by Ivanhoe Mines. A 26% interest is held by Ivanplats’ historically-disadvantaged, broad-based, black economic empowerment (B-BBEE) partners, which include 20 local host communities with approximately 150,000 people, project employees and local entrepreneurs. Ivanplats reached Level 4 contributor status in its most recent verification assessment on the B-BBEE scorecard. A Japanese consortium of ITOCHU Corporation, Japan Oil, Gas and Metals National Corporation, and Japan Gas Corporation, owns a 10% interest in Ivanplats, which it acquired in two tranches for a total investment of $290 million.

The Platreef Project hosts an underground deposit of thick, platinum-group metals, nickel, copper and gold mineralization on the Northern Limb of the Bushveld Igneous Complex in Limpopo Province – approximately 280 kilometres northeast of Johannesburg and eight kilometres from the town of Mokopane.

On the Northern Limb, platinum-group metals mineralization is primarily hosted within the Platreef, a mineralized sequence that is traced more than 30 kilometres along strike. Ivanhoe’s Platreef Project, within the Platreef’s southern sector, is comprised of two contiguous properties: Turfspruit and Macalacaskop. Turfspruit, the northernmost property, is contiguous with, and along strike from, Anglo Platinum’s Mogalakwena group of mining operations and properties.

Since 2007, Ivanhoe has focused its exploration and development activities on defining and advancing the down-dip extension of its original discovery at Platreef, now known as the Flatreef Deposit, which is amenable to highly-mechanized, underground mining methods. The Flatreef area lies entirely on the Turfspruit and Macalacaskop properties that form part of the company’s mining right.

Health and safety at Platreef

At the end of March 2021, the Platreef Project reached a total of 202,283 lost-time, injury-free hours worked in accordance with South Africa’s Mine Health and Safety Act, and Occupational Health and Safety Act. It has been more than six months since the last lost-time injury occurred at the Platreef Project.

Intermediate Life Support nurse Anna Lebea (left) giving a vaccine to Bernard Maruma, a graduate Electrical Engineer at the Platreef Project.

Arrangement of project-level financing of up to $420 million to advance development of Platreef

In February 2021, Ivanplats signed a non-binding term sheet with Orion Mine Finance, a leading international provider of production-linked stream financing to base and precious metals mining companies, for a $300 million gold, palladium and platinum streaming facility. The stream financing remains subject to completion of legal due diligence and structuring, as well as negotiation and execution of definitive documentation. The streaming facility is planned to be drawn down in four separate tranches, as needed, in parallel with the engineering studies to upgrade the Platreef 2020 PEA to a feasibility study and the changeover of Platreef’s Shaft 1 to a production shaft.

Ivanplats also appointed two prominent, international commercial banks – Societe Generale and Nedbank – as mandated lead arrangers for a senior project debt facility of up to $120 million. The senior project debt facility is scheduled to be utilized only after the streaming facility is fully drawn down. Definitive terms and conditions of the debt facility are subject to the completion of the feasibility study for Platreef’s phased development plan, completion of due diligence and structuring, as well as negotiation and execution of definitive documentation. Terms and conditions of the debt facility will be made available when finalized.

Shaft 1 changeover to a production shaft progressing well

The construction of the 996-metre-level station at the bottom of Shaft 1 was completed in July 2020. The completed Shaft 1 is located approximately 350 metres away from a high-grade area of the Flatreef orebody that is planned for bulk-scale, mechanized mining. The three development stations that will provide initial, underground access to the high-grade orebody have also been completed on the 750-, 850-, and 950-metre levels.

The changeover construction at Shaft 1, initially delayed following an accident on September 14, 2020, is progressing to plan and is on schedule for commencement of rock hoisting early in 2022. All equipment for the shaft changeover has been procured and is on site. The detailed engineering designs for the shaft changeover have been completed, reviewed and approved. The changeover work within the shaft will be conducted by Platreef’s experienced owners’ team.

The winder that was used to successfully sink Shaft 1 will be converted and re-equipped to function as the permanent rock, personnel and material winder for the life of mine. The shaft will be equipped with two 12.5-tonne skips (with hoisting capacity of 825,000 tonnes per year) and an interchangeable personnel and materials cage to accommodate the movement of personnel and materials up and down the shaft during the initial phase of mining.

The shaft will be equipped using rope guides for the main rock, personnel and materials conveyances. The stage and winder ropes used during the sinking phase have been removed, and the equipping stage, new permanent guide-ropes and new permanent hoisting ropes have been delivered to site. Further to this, an auxiliary winder will be installed mainly to function as a man winder during the main rock hoisting cycle.

The construction of the winder foundations is underway and will be completed in time for the auxiliary winder installation and commissioning. The headgear, both winders, equipping stage, conveyances and control systems will comply with the highest industry safety standards, with proven and tested safety and redundancy systems in place.

Newly-designed rock chutes will connect the conveyors feeding the concentrator plant and the waste rock area, from where the rock will be converted to cemented backfill and used for protection berms to contain storm water and reduce noise emissions.

The new ropes and the newly-designed and constructed equipping stage have successfully been installed. The equipping in the shaft is expected to commence in May 2021 for completion by end of March 2022. Following the completion of the changeover work in the underground stations, and establishment of the ore and waste passes, lateral underground mine development will commence toward high-grade ore zones.

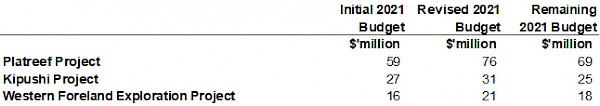

Early-works surface construction for Shaft 2 began in 2017. It includes the excavation of a surface box-cut to a depth of approximately 29 metres below surface and construction of the concrete hitch for the 103-metre-tall concrete headgear (headframe) that will house the shaft’s permanent hoisting facilities and support the shaft collar. Platreef’s initial budget for 2021 of $59 million, which included $10 million for commencement of headframe construction for Shaft 2, has been increased to $76 million with additional budget allocated toward detailed engineering designs, an alternative downstream processing option study and execution readiness. The Shaft 2 headframe construction, from the hitch to the collar level, recently commenced and is scheduled for completion in April 2022.

Sinah Tjale, Safety Officer, inspecting safety harnesses at the Platreef Mine. Ivanhoe is proud of the growing team of talented South African and Congolese women at all levels of the company.

Underground mining to incorporate highly productive, mechanized methods

Mining zones in the current Platreef mine plan occur at depths ranging from approximately 700 metres to 1,200 metres below surface. Initial access to the mine will be via the 996-metre-deep, 7.25-metre-diameter ventilation shaft (Shaft 1) that recently has been sunk to its final depth. Once expanded mine production is achieved, primary access to the mine will be by way of a 1,104-metre-deep, 10-metre-diameter production shaft (Shaft 2). During mine production, both shafts also will serve as ventilation intakes. Three additional ventilation exhaust raises (Ventilation Raise 1, 2, and 3) are planned to achieve steady-state production.

Mining will be performed using highly-productive mechanized methods, including long-hole stoping and drift-and-fill. Each method will utilize cemented backfill for maximum ore extraction. The production plans in both the PEA’s initial five-year drift-and-fill mining operation hoisting from Shaft 1 and the expansion when Shaft 2 is available, are focused on maximizing higher-grade areas, which was achieved through optimization based on stope locations, stope grades, mining method, and zone productivities. The orebody was targeted to recover approximately 125 million tonnes at the highest net smelter return.

The ore will be hauled from the stopes to a series of internal ore passes and fed to the bottom of the shafts, where it will be crushed and hoisted to surface.

Platreef employees working on the conversion and re-equipping of the permanent rock, personnel and material winder of the mine’s Shaft 1.

Development of human resources and job skills

Consultation regarding the Platreef Project’s second Social and Labour Plan (SLP) is in the final stages. In this second SLP, Ivanplats plans to build on the foundation laid in the first SLP and continue with its training and development suite, which includes 15 new mentors, internal skills training for 78 staff members, a legends program to prepare retiring employees with new/other skills, community adult education training for host community members, core technical skills training for at least 100 community members, portable skills training, and more. The Platreef Project continued supporting several educational programs and the provision of free Wi-Fi in host communities.

Local economic development projects will contribute to community water source development through the Mogalakwena Municipality boreholes program. Other projects, which will be undertaken in partnership with other parties, include the refurbishment and equipping of a clinic in Tshamahansi Village.

The enterprise and supplier development commitments comprise of expanding the existing kiosk and laundry facilities even further and adding expanded change house facilities to be managed by a community partner in the future. A five-year integrated business accelerator and funding project will assist community members to obtain help with development and supplier readiness.

Students at the Somavhuga High School in Tshamahansi Village, near the Platreef Project. Ivanhoe continues to invest in young people through educational support and enrichment such as scholarships, bursaries, internships and learnerships, as well as through the upkeep of Wi-Fi hotspots in support of e-learning.

3. Kipushi Project

68%-owned by Ivanhoe Mines

Democratic Republic of Congo

The Kipushi copper-zinc-germanium-silver-lead mine in the DRC is adjacent to the town of Kipushi and approximately 30 kilometres southwest of Lubumbashi. It is located on the Central African Copperbelt, approximately 250 kilometres southeast of the Kamoa-Kakula Project and less than one kilometre from the Zambian border. Ivanhoe acquired its 68% interest in the Kipushi Project in November 2011; the balance of 32% is held by the state-owned mining company, Gécamines.

Health and safety at Kipushi

At the end of March 2021, the Kipushi Project reached a total of 3,144,006 work hours free of lost-time injuries. It has been more than two years since the last lost-time injury occurred at the Kipushi Project.

Since temporarily suspending mine development operations due to the COVID-19 pandemic, the project maintained a reduced workforce to safely and cost-effectively maintain infrastructure and pumping systems and to execute planned projects.

The Kipushi Project operates a potable-water station for the daily supply of water to the municipality of Kipushi. This support includes power supply, disinfectant chemicals, routine maintenance, security, and emergency repair of leaks to the primary reticulation. Plans are underway for the establishment of additional solar-powered boreholes at a local school and in nearby communal areas.

The Kipushi Project supported educational initiatives in 2020 through continued renovations at the Mungoti School. The sewing training centre project established by the Kipushi Project continued producing cloth face masks – donating approximately 2,000 masks a month to host communities.

The Sustainable Livelihoods Program, which commenced in 2020 with a poultry farming initiative established for the benefit of a consortium of local women, progressed well with 300 chickens having been brought to market.

Kipushi’s definitive feasibility study in final stages of completion

The Kipushi Project’s pre-feasibility study (PFS), announced by Ivanhoe Mines on December 13, 2017, anticipated annual production of an average of 381,000 tonnes of zinc concentrate over an 11-year, initial mine life at a total cash cost of approximately $0.48 per pound (lb) of zinc.

Highlights of the PFS, based on a long-term zinc price of $1.10/lb, include:

- After-tax net present value (NPV) at an 8% real discount rate of $683 million.

- After-tax real internal rate of return (IRR) of 35.3%.

- After-tax project payback period of 2.2 years.

- Pre-production capital costs, including contingency, of $337 million.

- Existing surface and underground infrastructure allow for significantly lower capital costs than comparable greenfield development projects.

- Life-of-mine average planned zinc concentrate production of 381,000 dry tonnes per annum, with a concentrate grade of 59% zinc, is expected to rank Kipushi, once in production, among the world’s largest zinc mines.

All figures are on a 100%-project basis unless otherwise stated. Estimated life-of-mine average cash cost of $0.48/lb of zinc is expected to rank Kipushi, once in production, in the bottom quartile of the cash-cost curve for zinc producers internationally.

The draft feasibility study, together with the development and financing plan for Kipushi, are being reviewed by Ivanhoe Mines together with its partner Gécamines. It is anticipated that these discussions will be concluded with the finalization of the feasibility study and the agreement on the development and financing plan by mid-2021.

Project development and infrastructure

Although development and rehabilitation activities in Q1 2021, as well as for the year ending December 31, 2020, were limited, significant progress has been made in recent years to modernize the Kipushi Mine’s underground infrastructure as part of preparations for the mine to resume commercial production, including upgrading a series of vertical mine shafts to various depths, with associated headframes, as well as underground mine excavations and infrastructure. A series of crosscuts and ventilation infrastructure still is in working condition and have been cleared of old materials and equipment to facilitate modern, mechanized mining. The underground infrastructure also includes a series of high-capacity pumps to manage the mine’s water levels, which now are easily maintained at the bottom of the mine.

Shaft 5 is eight metres in diameter and 1,240 metres deep and has been upgraded and re-commissioned. The main personnel and material winder has been upgraded and modernized to meet international industry standards and safety criteria. The Shaft 5 rock-hoisting winder also is fully operational with new rock skips, new head- and tail-ropes, and attachments installed. The two newly-manufactured rock conveyances (skips) and the supporting frames (bridles) have been installed in the shaft to facilitate the hoisting of rock from the main ore and waste storage silos feeding rock on the 1,200-metre level.

Cyril Muke checking the variable speed drives for the large-capacity Grifo water pumps that are keeping Kipushi’s underground operations dry.

The main haulage way on the 1,150-metre level, between the Big Zinc access decline and Shaft 5 rock load-out facilities, has been resurfaced with concrete so the mine now can use modern, trackless, mobile machinery. A new truck-tipping bin, which feeds into the large-capacity rock crusher located directly below, has been installed on this level. The old winder at P2 Shaft has been removed and construction of the new foundation, along with assembly and installation of the new modern winder, has been completed and fully commissioned after passing safety inspection and testing procedures.

Alain Mutomo, Garcao Ilunga and Christophe Ngandu (L-R) surveying underground at Kipushi in preparation for resumption of mining activities.

Young Kipushi residents on their way to collect water from the solar-powered water wells installed by the Kipushi Project.

4. Western Foreland Exploration Project

100%-owned and 90%-owned by Ivanhoe Mines

Democratic Republic of Congo

Ivanhoe’s DRC exploration group is targeting Kamoa-Kakula-style copper mineralization through a regional exploration and drilling program on its Western Foreland exploration licences, located to the north, south and west of the Kamoa-Kakula Project. Ivanhoe’s Western Foreland Exploration Project consists of 17 licences that cover a combined area of approximately 2,550 square kilometres.

Exploration models that successfully led to the discoveries of Kakula, Kakula West, and the Kamoa North Bonanza Zone on the Kamoa-Kakula joint-venture mining licence, are being applied to the Western Foreland extensive land package by the same team of exploration geologists responsible for the previous discoveries.

Exploration activities at the Western Foreland area continued during Q1 2021 with the field season restarting in mid-February. The target of the 2021 field season is to start drill testing some of the new permits and generate more targets. Initial drill programs in Q1 2021 were planned close to current access routes and to follow up on Makoko West extension discoveries made in 2020. The drill core from the program is being processed for analysis and detailed rock physical property test work also is being done to further geological understanding, as well as the ability of the data to be used for future larger-scale geophysical test work and analysis.

In Q1 2021, a total of eleven new diamond drill holes were completed at the Makoko West area. The drilling aimed to further delineate the continuation of prospective lower Nguba stratigraphy westwards toward the new exploration permits from initial drilling in 2020. Diamond drilling was completed on northwest-southeast fences every 1,000 metres, with typically two to three holes drilled on each fence and spaced approximately 400 metres apart. Holes drilled generally were around 150 to 450 metres deep, with some shallower holes. A total of 2,725 metres were drilled during the quarter. Exploration continued on the Western Foreland exploration licences with strict procedures in place to protect employees and drilling contractors from COVID-19.

On February 10, 2021, Ivanhoe Mines announced that assay results from drilling completed in early 2020 confirm the extension of the Kamoa North high-grade copper structure for at least 800 metres in the Kiala Discovery area.

The high-grade copper zone at the Kiala Discovery was originally discovered on the Kamoa-Kakula mining licence and delineated through a series of step-out fences of holes drilled on 100-metre spacings in a northerly direction onto Ivanhoe’s 100%-owned exploration licences.

The structure controlling the zone of high-grade copper remains open to the north, and Ivanhoe now has secured 35 kilometres of highly prospective, 100%-owned exploration ground along trend and to the north of the Kiala Discovery.

Selected drill holes at the Kiala Discovery include:

- DKIA_DD007 intersected 7.21 metres (true width) of 7.98% copper, at a 1% and 2% copper cut-off, from 345.44 metres down hole.

- DKIA_DD011 intersected 3.82 metres (true width) of 5.35% copper, at a 1% and 2% copper cut-off, from 348.00 metres down hole.

- DKIA_DD014 intersected 5.30 metres (true width) of 12.42% copper, at a 1% and 2% copper cut-off, from 366.70 metres down hole.

- DKIA_DD016 intersected 3.59 metres (true width) of 9.71% copper, at a 1% and 2% copper cut-off, from 351.40 metres down hole.

On February 10, 2021, Ivanhoe Mines also announced that drilling at the Makoko Sud Discovery intercepted significant, shallow copper mineralization (including up to 6.01 metres grading 3.38% copper) over a 7.5-kilometre strike length in a south-westerly direction along strike from the initial Makoko Sud Discovery area.

Significant new drill intercepts from Makoko West include:

- DMKK_DD117, a 3.6-kilometre step-out hole from previous Makoko Sud drilling, intersected 6.01 metres (true width) of 3.38% copper, at a 2% copper cut-off from 259.72 metres down hole and 9.75 metres (true width) of 2.63% copper at a 1% copper cut-off.

- DMKK_DD118, a 1.6-kilometre step-out hole from previous Makoko Sud drilling, intersected 4.19 metres (true width) of 3.01% copper, at a 2% copper cut-off from 209.50 metres down hole and 5.15 metres (true width) of 2.78% copper at a 1% copper cut-off.

- DMKK_DD123, a 7.5-kilometre step-out hole from previous Makoko Sud drilling, intersected 3.33 metres (true width) of 1.44% copper, at a 2% copper cut-off from 570 metres down hole and 17.77 metres (true width) of 1.39% copper at a 1% copper cut-off.

The recent Makoko West drilling is extremely significant for the exploration potential of the new exploration permits as it demonstrates that the target stratigraphy extends westward and that the copper mineralizing system on the western edge of the basin is laterally extensive. Future drilling in the Makoko West area will target specific structural locations that are conducive to developing higher copper grades.

A high-resolution magnetic and radiometric survey started during Q4 2020 with 61% of the data acquisition completed. This program has been put on hold while ground-water level drops as this could affect the survey quality. The program will be completed during Q2 2021.

Construction of a 16-kilometre road to gain access to new exploration target areas on the new western permits continued during Q1 2021, running from the Makoko exploration area out to the west and now is nearly complete. In addition, a new bridge over the Lubudi River currently is being constructed, with a new 60-kilometre access spine road planned for the other side of the new bridge to access the new permits to the southwest targeted for exploration during 2021.

The initial 2021 budget was $16 million and now has been increased to $21 million to include additional drilling, surveys and field-work vehicles. The budget may be further expanded based on program results. The increased 2021 exploration program now includes 60,000 metres of combined aircore and diamond drilling, airborne, electromagnetic and ground-based geophysics, soil sampling, road construction and additional field-work vehicles. Much of this year’s exploration will focus on the more than 1,700 square kilometres of new, 100%-owned permits that were acquired in 2019 and received environmental certification in 2020.

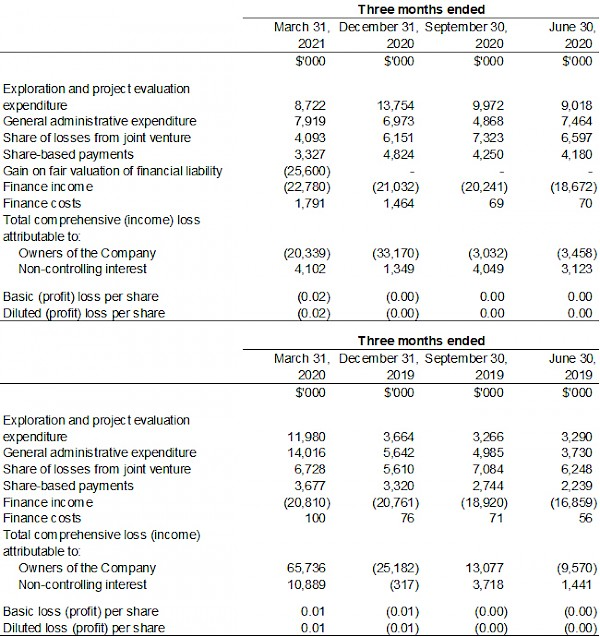

SELECTED QUARTERLY FINANCIAL INFORMATION

The following table summarizes selected financial information for the prior eight quarters. Ivanhoe had no operating revenue in any financial reporting period and did not declare or pay any dividend or distribution in any financial reporting period.

DISCUSSION OF RESULTS OF OPERATIONS

Accounting for the convertible notes closed in March 2021

The company closed a private placement offering of $575.0 million of 2.50% convertible senior notes maturing in 2026 on March 17, 2021. Upon conversion, the convertible notes may be settled, at the company’s election, in cash, common shares or a combination thereof. Due to this election right, the convertible notes have an embedded derivative liability that is measured at fair value with changes in value being recorded in profit or loss, as well as the host loan that is accounted for at amortized cost.

The convertible senior notes are senior unsecured obligations of the company which will accrue interest payable semi-annually in arrears at a rate of 2.50% per annum and will mature on April 15, 2026, unless earlier repurchased, redeemed or converted. The initial conversion rate of the notes is 134.5682 Class A common shares of the company per $1,000 principal amount of notes, or an initial conversion price of approximately $7.43 (equivalent to approximately C$9.31) per common share.

Holders of the notes may convert the notes, at their option, in integral multiples of $1,000 principal amount, or in excess thereof, at any time until the close of business on the business day immediately preceding October 15, 2025, but only under the following circumstances:

- during any calendar quarter commencing after the calendar quarter ending on June 30, 2021 (and only during such calendar quarter), if the last reported sale price of the Company’s Class A common shares for at least 20 trading days (whether or not consecutive) during a period of 30 consecutive trading days ending on, and including, the last trading day of the immediately preceding calendar quarter is greater than or equal to 130% of the conversion price on each applicable trading day; or

- during the five consecutive business day period after any ten consecutive trading day period (the “measurement period”) in which the trading price per $1,000 principal amount of notes for each trading day of the measurement period was less than 98% of the product of the last reported sale price of the Company’s Class A common shares and the conversion rate on each such trading day; or

- if the Company calls any or all of the notes for redemption in certain circumstances or upon the occurrence of certain corporate events.

On or after October 15, 2025 until the close of business on the second scheduled trading day immediately preceding the maturity date, holders may convert all or any portion of their notes, in multiples of $1,000 principal amount, at the option of the holder regardless of the foregoing conditions.

The convertible notes will not be redeemable at the company’s option prior to April 22, 2024, except upon the occurrence of certain tax law changes. On or after April 22, 2024 and on or prior to the 41st scheduled trading day immediately preceding the maturity date, the notes will be redeemable at the company’s option if the last reported sale price of the company’s common shares has been at least 130% of the conversion price then in effect for at least 20 trading days (whether or not consecutive) during any 30 consecutive trading day period (including the last trading day of such period) ending on, and including, the trading day immediately preceding the date on which the company provides notice of redemption at a redemption price equal to 100% of the principal amount of the convertible notes to be redeemed, plus accrued and unpaid interest to, but excluding, the redemption date.

Due to the fact that upon conversion, the notes may be settled, at the company’s election, in cash, common shares or a combination thereof, the conversion feature is a derivative financial liability. The effect of this is that the host liability will be accounted for at amortized cost, with an embedded derivative liability being measured at fair value with changes in value being recorded in profit or loss.

The effective interest rate of the host liability was deemed to be 9.39%. The carrying value of the host liability was $415.7 million as at March 31, 2021.

The derivative liability had a fair value of $150.5 million on closure of the convertible notes offering, which decreased to $124.9 million as at March 31, 2021, resulting in a gain on fair valuation of financial liability of $25.6 million for Q1 2021.

The following key inputs and assumptions were used in determining the fair value of the embedded derivative liability on March 17, 2021 at initial recognition:

- Share price of C$7.00.

- A credit spread of 630 basis points.

- Volatility of 42%.

- Borrowing cost of 50 basis points.

The key inputs and assumptions used at March 31, 2021 was:

- Share price of C$6.47.

- A credit spread of 610 basis points.

- Volatility of 42%.

- Borrowing cost of 50 basis points.

Transaction costs on the convertible notes offering relating to the derivative liability amounted to $3.7 million and was expensed and included in the profit for the period.

Review of the three months ended March 31, 2021 vs. March 31, 2020

The company recorded a total comprehensive profit of $16.2 million for Q1 2021 compared to a loss of $76.6 million for the same period in 2020. The comprehensive loss for Q1 2020 included an exchange loss on translation of foreign operations of $62.5 million, resulting from the weakening of the South African Rand by 28% from December 31, 2019, to March 31, 2020, compared to an exchange loss on translation of foreign operations recognized in Q1 2021 of $4.2 million.

As explained above, the company recognized a gain on fair valuation of the embedded derivative financial liability of $25.6 million for Q1 2021 and transaction costs on the convertible notes offering relating to the derivative liability was expensed and amounted to $3.7 million.

Finance income for Q1 2021 amounted to $22.8 million, and was $2.0 million more than for the same period in 2020 ($20.8 million). Included in finance income is the interest earned on loans to the Kamoa Holding joint venture to fund operations that amounted to $21.2 million for Q1 2021, and $16.3 million for the same period in 2020, and increased as the accumulated loan balance increased. Interest received on cash and cash equivalents decreased due to US interest rate cuts by the Federal Reserve.

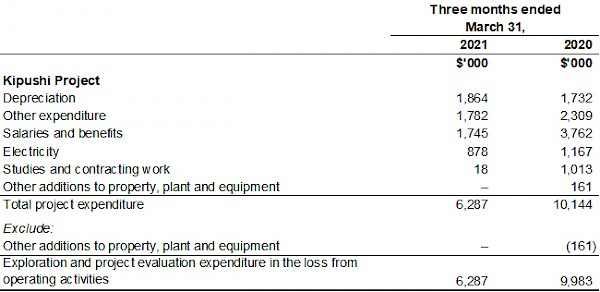

Exploration and project expenditure amounted to $8.7 million in Q1 2021 and $12.0 million for the same period in 2020. Exploration and project expenditure related to exploration at Ivanhoe’s Western Foreland exploration licences and amounts spent at the Kipushi Project which was on reduced activities and incurred limited cost of a capital nature in the periods. The main classes of expenditure at the Kipushi Project in Q1 2021 and Q1 2020 are set out in the following table:

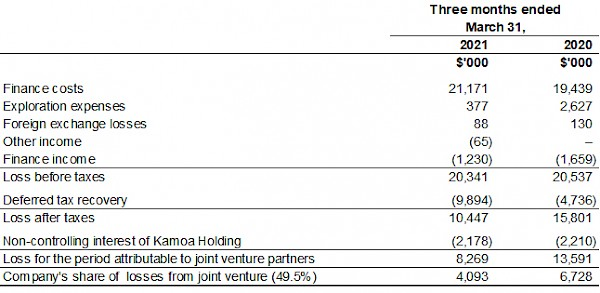

The company’s share of losses from the Kamoa Holding joint venture decreased from $6.7 million in Q1 2020 to $4.1 million in Q1 2021. The following table summarizes the company’s share of losses of the joint venture for the three months ended March 31, 2021, and for the same period in 2020:

The finance costs in the Kamoa Holding joint venture relates to shareholder loans where each shareholder is required to fund Kamoa Holding in an amount equivalent to its proportionate shareholding interest. The company is advancing Crystal River’s portion on its behalf in return for an increase in the promissory note due to Ivanhoe.

Financial positionas at March31, 2021 vs. December31, 2020

The company’s total assets increased by $559.0 million, from $2,417.1 million as at December 31, 2020, to $2,976.1 million as at March 31, 2021. The main reason for the increase in total assets was the receipt of the net proceeds from the convertible senior notes that closed on March 17, 2021. The net proceeds from the sale of the convertible notes, after deducting the expenses of the offering that related to the host liability of $10.3 million, was $564.7 million.

Cash and cash equivalents increased by $469.1 million, from $262.8 million as at December 31, 2020, to $731.9 million as at March 31, 2021 due to the receipt of the convertible note proceeds. The company utilized $20.2 million of its cash resources in its operations and advanced loans of $70.0 million to the Kamoa Holding joint venture during the three months ended March 31, 2021.

The company’s total liabilities increased by $537.2 million to $617.8 million as at March 31, 2021, from $80.6 million as at December 31, 2020, with the increase also due to the private placement offering of $575.0 million of 2.50% convertible senior notes described above.

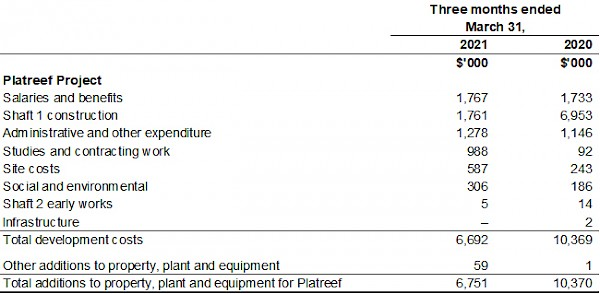

The net increase of property, plant and equipment amounted to $0.5 million, with additions of $6.8 million to project development and other property, plant and equipment. Of this total, $6.7 million pertained to development costs and other acquisitions of property, plant and equipment at the Platreef Project.

The main components of the additions to property, plant and equipment – including capitalized development costs – at the Platreef Project for the three months ended March 31, 2021, and for the same period in 2020, are set out in the following table:

Costs incurred at the Platreef Project are deemed necessary to bring the project to commercial production and are therefore capitalized as property, plant and equipment.

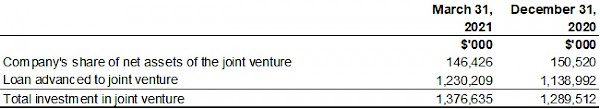

The company’s investment in the Kamoa Holding joint venture increased by $87.1 million from $1,289.5 million as at December 31, 2020, to $1,376.6 million as at March 31, 2021, with each of the current shareholders funding the operations equivalent to their proportionate shareholding interest. The company’s portion of the Kamoa Holding joint venture cash calls amounted to $70.0 million during the three months ended March 31, 2021, while the company’s share of losses from the joint venture amounted to $4.1 million.

The company’s investment in the Kamoa Holding joint venture can be broken down as follows:

The Kamoa Holding joint venture principally uses loans advanced to it by its shareholders to advance the Kamoa-Kakula Project through investing in development costs and other property, plant and equipment, as well as continuing with exploration. This can be evidenced by the movement in the company’s share of net assets in the Kamoa Holding joint venture which can be broken down as follows:

The Kamoa Holding joint venture completed the draw-down of EUR 45 million (approximately $56 million) of the equipment financing and $9 million of the down-payment facilities in late December 2020 and EUR 5.9 million (approximately $7.2 million) of the equipment financing in Q1 2021. The equipment finance is secured only by the equipment that is being financed and has an effective interest rate of 8.96%. The down-payment facility is unsecured and has an effective interest rate of 11.58%.

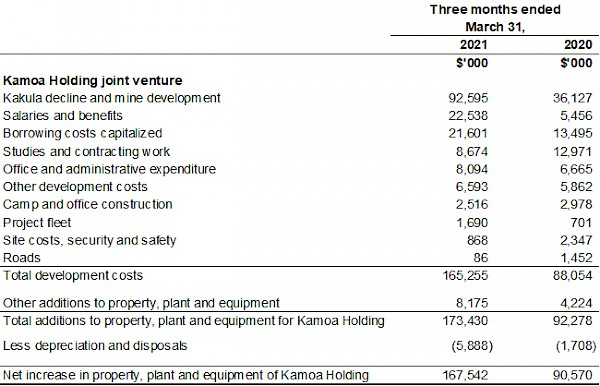

The Kamoa Holding joint venture’s net increase in property, plant and equipment from December 31, 2020, to March 31, 2021, amounted to $167.5 million and can be further broken down as follows:

LIQUIDITY AND CAPITAL RESOURCES

The company had $731.9 million in cash and cash equivalents as at March 31, 2021. At this date, the company had consolidated working capital of approximately $781.8 million, compared to $308.0 million at December 31, 2020.

Since December 8, 2015, each shareholder in Kamoa Holding has been required to fund Kamoa Holding in an amount equivalent to its proportionate shareholding interest. The company is advancing Crystal River’s portion on its behalf in return for an increase in the promissory note due to Ivanhoe.

The Platreef Project’s current expenditure is being funded solely by Ivanhoe, through an interest bearing loan to Ivanplats, as the Japanese consortium has elected not to contribute to current expenditures.

The company’s main objectives for the remainder of 2021 at the Platreef Project is the detailed engineering and updated feasibility study for the phased development plan, progression of the Shaft 1 changeover and the construction of the Shaft 2 headframe to the collar. At Kipushi, cost-saving measures will continue until the finalization of the feasibility study and the development and financing plan is agreed. Mine development at the Kamoa-Kakula Project continues with first production expected later this month or early June 2021 and the Phase 2 concentrator expansion is being fast tracked.

Ivanhoe’s board of directors allocated increased 2021 budgets to each of the Platreef, Kipushi and Western Foreland’s exploration projects. The budget increases and amounts remaining for the remainder of 2021 are set out in the following table:

The company’s proportionate funding of the Kamoa-Kakula Project is expected to be $158million for the remainder of 2021, with the assumption that additional equipment purchases would be funded through the equipment financing facilities and that the limited recourse line of credit from Zijin is not drawn.

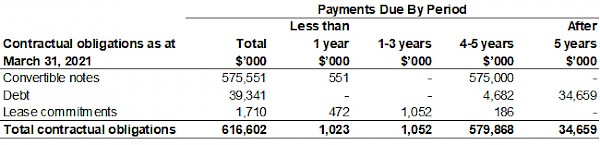

On 17 March 2021, the company closed a private placement offering of $575 million of 2.50% convertible senior notes maturing in 2026. The convertible senior notes are senior unsecured obligations of the company which will accrue interest payable semi-annually in arrears at a rate of 2.50% per annum and will mature on April 15, 2026, unless earlier repurchased, redeemed or converted.

The notes will be convertible at the option of holders, prior to the close of business on the business day immediately preceding October 15, 2025, only under certain circumstances and during certain periods, and thereafter, at any time until the close of business on the second scheduled trading day immediately preceding the maturity date. Upon conversion, the notes may be settled, at the company’s election, in cash, common shares or a combination thereof.

The carrying value of the host liability was $415.7 million and the fair value of the embedded derivative liability was $124.9 million as at March 31, 2021.The company has a mortgage bond outstanding on its offices in London, United Kingdom, of £3.2 million ($4.4 million). The bond is fully repayable on August 28, 2025, secured by the property and incurs interest at a rate of GBP 1 month LIBOR plus 1.9% payable monthly in arrears. Only interest will be payable until maturity.

In 2013, the company became party to a loan payable to ITC Platinum Development Limited, which had a carrying value of $32.4 million as at March 31, 2021, and a contractual amount due of $34.7 million. The loan is repayable once the Platreef Project has residual cashflow, which is defined in the loan agreement as gross revenue generated by the Platreef Project, less all operating costs attributable thereto, including all mining development and operating costs. The loan attracts interest of USD 3 month LIBOR plus 2% calculated monthly in arrears. Interest is not compounded. The difference of $2.3 million between the contractual amount due and the carrying value of the loan is the benefit derived from the low-interest loan.

The company has an implied commitment in terms of spending on work programs submitted to regulatory bodies to maintain the good standing of exploration and exploitation permits at its mineral properties. The following table sets forth the company’s long-term obligations:

Debt in the above table represents the mortgage bond owing to Citibank and loan payable to ITC Platinum Development Limited, as described above.

The company is required to fund its Kamoa Holding joint venture in an amount equivalent to its proportionate shareholding interest.

This news release should be read in conjunction with Ivanhoe Mines’ Q1 2021 Financial Statements and Management’s Discussion and Analysis report available at www.ivanhoemines.com and at www.sedar.com.

![]()