Used oil pioneer BME grows its green partnerships

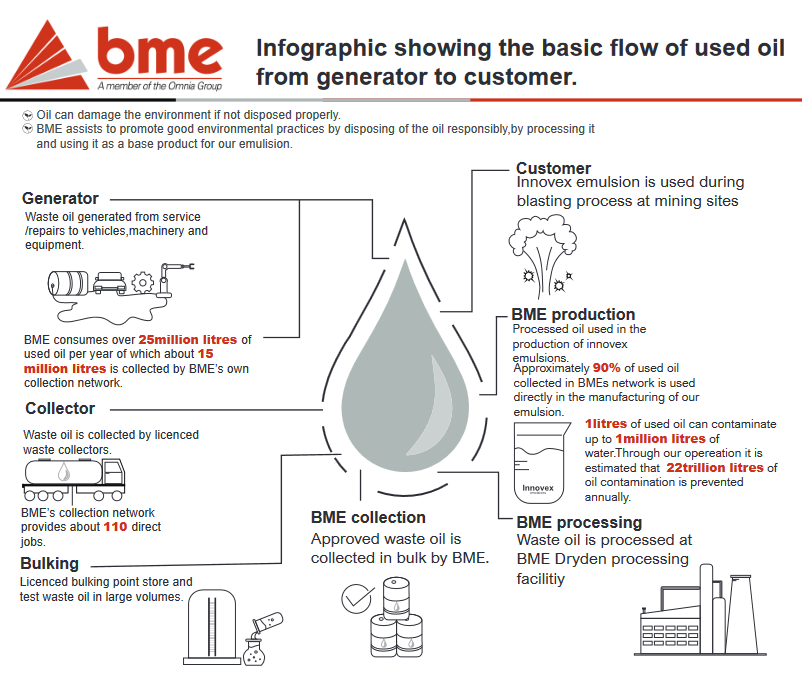

Leading the field in the way it incorporates used oil into its emulsion explosives, Omnia Group company BME is extending the benefits of this growing sustainability initiative to mining customers and other approved partners.

With its innovative culture and decades of successful blasting operations, BME has become the leading consumer of used oil in the explosives sector. This harmful waste product is used as a fuel agent in the company’s high-quality emulsions, ensuring that it is safely disposed of during the blasting process.

“Through our large collection network, we can ensure that used oil from customers and other sources does not find its way into valuable water resources or soil as a contaminant,” said Ramesh Dhoorgapersadh, BME’s General Manager for Safety, Health, Environment and Quality (SHEQ). “This helps us fulfil the Omnia vision of protecting life, sustaining livelihoods and creating a better world.”

BME consumes almost 25-million litres of used oil annually in South Africa alone and plans to increase its collection and processing capacity steadily in the years to come. It has been estimated that it takes only a litre of oil to contaminate a million litres of water, making the safe disposal of oil a strategic global imperative – especially for water-scarce countries. Dhoorgapersadh emphasised the alignment of BME’s used oil initiative with the United Nation’s Sustainable Development Goals (SDGs) – which focus on goals such as access to clean water, food security and eradicating pollution.

“It is important to appreciate the ecosystem impact of oil in the environment,” he said. “Contamination not only poisons water but can affect food security by undermining the health of soil and agriculture.”

BME was therefore reaching out to partner with mining and other players to promote the SDGs in pursuit of a sustainable future for the planet. He emphasised, however, that the collection, testing, treatment and utilisation of used oil is a complex and demanding process. It cannot be reliably conducted without a robust infrastructure and meticulous attention to quality in every step of the operation.

Dirk Voogt, BME’s General Manager for Production and Logistics, explained that the company’s oil collection network has evolved over many years – aligning each phase with its ISO 9000 quality certification. It is also registered as an approved collector and processor with the Recycling Oil Saves the Environment (ROSE) Foundation.

“Our extensive logistical arrangements include taking used oil from our mining customers, but also from our network of 11 approved suppliers – or bulking points,” said Voogt. “The oil is processed and tested at our dedicated facility in Delmas, from where it can be channelled into our emulsion production.”

Driving its increasing consumption levels is BME’s expanding business and its leading emulsion technology which can incorporate steadily higher proportions of used oil in comparison to conventional fuel agents. He notes that its used oil capability is not limited to South Africa but has been applied for mining customers as far afield as West Africa and Indonesia.

“We can collect all the used motor oil from a mine’s vehicles on a regular basis, providing a safe and environmentally sound service that is very convenient for the customer,” he said. “The responsible disposal of the oil in our emulsion adds another dimension to our partnership with mining customers – supporting their sustainability efforts while reducing their logistical load and environmental risk.”

The environmental, social and governance (ESG) benefits extend further than this, said Sachin Govender, Used Oil Manager at BME. He explained that small businesses are among the most important contributors to the success of the company’s used oil collection network. The initiative therefore creates long-term business opportunities in the local economy, stimulating entrepreneurial activity and generating jobs.

“Our infrastructure relies on small and micro-businesses to collect oil in a compliant manner from a range of sectors outside mining such as vehicle maintenance workshops,” said Govender. “This has led to a bulking point network that already provides employment for over 120 people in South Africa.”

He noted that BME is expanding this initiative into neighbouring countries where it can draw on small – even informal – businesses to collect used oil, thus creating demand in the local economy. The company’s regular and growing demand for used oil provides a solid platform for these small businesses to develop their expertise and standards, so they can fulfil this demand into the future.

Voogt highlighted that the used oil methodology employed in Indonesia is applied on a remote mining site, where BME manufactures emulsion for its customer. Despite the remote location, the manufacturing process can achieve loading levels – of used oil relative to virgin fuels – similar to those in South African operations.

“We are also taking this technology into our other operations around the globe,” he said. “Wherever there are sufficient sources of used oil, we can put the equipment and processes in place to support the principles of a more circular economy.”

The important impact of BME’s used oil initiative was recently recognised by the Chemical and Allied Industries’ Association (CAIA). In CAIA’s annual awards to the sector, it gave BME the Responsible Care® initiative of the year award in the Category A segment.

To watch a video about BME’s used oil initiative, click the links below:

Images and captions:

Follow this QR code to visit BME’s Used Oil website

BME’s emulsions contain used oil as a fuel agent

BME’s used oil truck collects used oil from customers

Bios:

Dirk Voogt is BME’s General Manager: Production and Logistics, having joined the company in 2000 as Plant Manager. Voogt oversees all BME’s manufacturing plants in South Africa, including those producing emulsifier, bulk emulsion, cartridge explosives and packaged ANFO, as well as shock tube and electronic delay detonation systems. He manages the plants’ efficiencies, quality control and human capital among other aspects. His qualifications include a degree in chemical engineering from the University of Pretoria, a certificate in explosives technology for supervision and management, and various courses on explosives management.

Ramesh Dhoorgapersadh is BME’s General Manager for Safety, Health, Environment and Quality (SHEQ). He has over 30 years of industrial experience and covers all aspects of safety, health, environment, quality and sustainability at BME. This includes strategic SHERQ management of a multitude of operations and distribution sites across Africa, Indonesia, Australia, Canada and USA, as well as managing the security and regulatory requirements of explosive manufacture and distribution. His qualifications include an MBA from Mancosa and a degree in industrial technology and management from the Production Management Institute.

As Used Oil Manager at BME, Sachin Govender is responsible for the P&L performance for the unit with specific objective to formulate and lead the implementation of BME’s Used oil strategy and operating framework (commercial, strategic sourcing, logistics, SHERQ and market development) across the Southern African region. He holds a degree from The University of the Witwatersrand in business administration and management, as well as a degree in supply chain and operations management from UNISA.

About BME

Blasting and explosives company, BME is an integrated provider of safe, smart, sustainable blasting solutions – collaborating closely with customers and business partners to create value across the blasting cycle. Together with Protea Mining Chemicals, BME forms the mining division of the Omnia Group – a JSE listed diversified provider of specialised chemical products and services used in the mining, agriculture, and chemicals sectors.

Formed over three decades ago on the strength of a new cold emulsion technology that has since become an industry standard, BME offers innovative products and services at every stage in the blasting supply chain. As a mid-tier, global manufacturer and supplier of explosives, related accessories and blasting services to the mining, quarrying and construction industries, its continuous improvement is driven by an agile, solutions-based approach. Its commitment to operational excellence ensures customers of fit-for-purpose solutions that optimise mining efficiency – delivered reliably through its secure supply chain. The company is committed to environmental social and governance (ESG) initiatives to underpin our sustainable strategies that protect life, sustain livelihoods, and leave a better world.

BME’s footprint covers 17 African counties including South Africa, Namibia, Botswana, Zimbabwe, Zambia, Swaziland, Angola, Malawi, Mozambique, DRC, Sierra Leone, Mali, Burkina Faso, Mauritania, Senegal and Eritrea. The company also has legal entities in Australia, Canada, Indonesia and the USA.

![]()